.gif)

MENU

|

Man in Space

A National Historic Landmark Theme Study |

|

|

National Advisory Committee for Aeronautics Wind Tunnels |

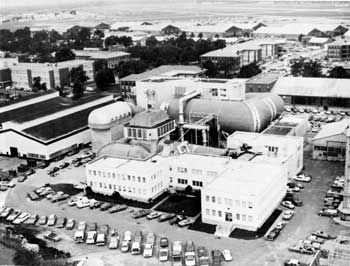

Exterior view of Eight-Foot High Speed Tunnel, 1981

(Courtesy of NASA, NASA/Langley Research Center Facilities Office)

Eight-Foot High Speed Tunnel

| Name: | Eight-Foot High Speed Tunnel (Eight-Foot Transonic Tunnel) |

| Location: | Langley Research Center, Hampton, Virginia |

| Owner: | National Aeronautics and Space Administration (NASA) |

| Condition: | Good, unaltered, original site |

| Builder/Architect: | NACA |

| Dates: | 1936-1956 |

DESCRIPTION

The Eight-Foot High Speed Tunnel is a single-return atmospheric pressure tunnel with an 8-foot diameter closed-throat test section. The tunnel became operational in 1936 and at that time had a maximum speed of Mach 0.75 driven by an 8,000-horsepower electric motor/fan.

The design of the Eight Foot High Speed Tunnel was

complicated by two problems. [1]

The first problem involved the effect discovered in 1738 by the Swiss mathematician Daniel Bernoulli who observed that as the velocity of flow in a duct is increased by constricting the cross sectional area, the static pressure of the fluid drops. In wind tunnel design, this means that the air pressure in the chamber containing the high-velocity test section will be lower than in the rest of the tunnel. Thus, for the tunnel, the test chamber had to withstand a powerful, inwardly directed pressure. [2]

One method to solve this problem would have been to construct a welded steel pressure vessel around the test section. In an effort to solve the pressing unemployment problem then existing as a result of the Depression, NACA engineers decided to use locally available unskilled labor and build the entire tunnel of reinforced concrete. An igloo-like structure around the test sections was built with walls 1 foot thick. The igloo was essentially a low pressure chamber—just the opposite of the VDT. Operating personnel in the igloo were subjected to pressures that were the equivalent of 10,000 feet altitude and had to wear oxygen masks and enter through airlocks. [3]

The second new problem that was created had to do with the mechanical energy that the 8,000-horsepower fan added to the airstream. NACA engineers calculated that this additional heat would cause the temperature within the tunnel to rise ten degrees per second until it reached the stage at which the amount of heat seeping through the concrete walls would equal the input of heat from the fan. Before this would happen the temperature within the tunnel would reach several thousand degrees.

The task of providing a cooling system was given to Russell G. Robinson who devised a ventilating tower that periodically allowed a small amount of heated air to escape in exchange for fresh cool air. This system proved to be successful and was accomplished with a loss of only one percent of power. This same principle was later applied to many other high speed tunnels. [4]

The Eight-Foot High Speed Tunnel was repowered in 1945 to 16,000-horsepower. By 1950 a slotted throat design was added to the test section that enabled the tunnel to be operated as a transonic tunnel. In 1953 the tunnel was repowered to 25,000-horsepower to yield a speed of Mach 1.2. A schlieren apparatus was also added to the test section of the tunnel to increase the capability for visual flow studies.

The Eight-Foot High Speed Tunnel was deactivated in 1956 and is now abandoned in place. The original test section of the tunnel is used for storage.

STATEMENT OF SIGNIFICANCE

The Eight-Foot High Speed Tunnel is a landmark in wind tunnel design. At the time of the construction of the High Speed Tunnel, NACA had only two small high speed tunnels (the 11" and 24" tunnels) to test aircraft design in speeds ranging from Mach 0.5 to Mach 0.9. While useful, these small tunnels had two severe limitations. First, the small size of these tunnels meant than only small scale models could be tested. This meant that test results were suspect if high Reynolds numbers could not be obtained. Second, both tunnels were powered by the rapid blowdown of the VDT and were thus restricted to tests lasting less than a minute.

The Eight-Foot High Speed Tunnel solved both of these problems. It was large enough to accommodate sizeable test models and even complete aircraft parts on occasion. It was also a continuous flow tunnel that could operate almost indefinitely thereby giving the engineers sufficient time to run their tests and to check their test results. For the first time NACA engineers had a research tool that could supply high speed test results on a large scale.

Over the years NACA engineers continued to modify and upgrade the Eight-Foot High Speed Tunnel. After the Second World War NACA engineers began to work on improving wind tunnel performance in the transonic range (Mach 0.7 to Mach 1.4). It had long been known that airflow within the test section of a transonic wind tunnel did not represent the actual conditions of free flight. The problem was that the natural pattern of airflow in this range is disturbed and altered by the existence of the walls of the tunnel. This problem became severe in the area of Mach 1 and was known as the tunnel choking effect. Until this problem was solved accurate test results were not possible for transonic tunnels.

Attempts to solve this problem by making smaller models proved unsuccessful when lower Reynolds numbers were obtained. Attempts to eliminated the walls of the tunnel in the area of the test section also proved less than satisfactory. In 1946 Ray Wright at Langley analyzed the potentialities of a partially open or slotted wind tunnel wall. His results suggested that slots occupying about 6 percent of the wall would closely duplicate free-air conditions. [5]

This solution was quickly applied to the Eight-Foot High Speed Tunnel. In February 1950 the tunnel was shut down and slotted walls were added to the test section. The concept worked and NACA now had the first wind tunnel in the world that would give accurate test results in the transonic range. Since all supersonic aircraft would have to fly briefly in the transonic range, knowing what happened to aircraft in this transition zone was critical to the supersonic fighters and bombers being planned in the postwar era. The slotted wall concept was immediately put to work testing the next generation of American aircraft.

After February 1950 the name of the Eight-Foot High Speed Tunnel was changed to the Eight-Foot Transonic Tunnel. Before the tunnel was phased out of operation in 1956 critical tests led to the discovery of the famous Area Rule which dictated that the fuselage of supersonic aircraft should be constricted where the wings are attached and then expanded at their trailing edges. This eliminated the possibility of generating strong shock waves behind an aircraft that can act as a drag on speed.

Many modern wind tunnels are derived from the technology extended or developed at Langley by NACA engineers. The Variable Density Tunnel was the world's first pressurized wind tunnel. The Full Scale Wind Tunnel was exactly that, full scale and thus able to conduct important drag cleanup tests for modern aircraft. The Eight-Foot High Speed Tunnel was the first continuous flow high speed tunnel able to test large models and actual working parts of airplanes. The addition of the slotted throat design was revolutionary for its time and gave accurate wind tunnel data in the transonic range. Many modern wind tunnels incorporate some variation of these features of pressure, large scale, high speed, continuous flow, and slotted throat design. These three tunnels marked the emerging technological superiority of the American aircraft industry. After the Second World War this technology was to provide the base upon which Americans would begin to construct rockets that would eventually fly to the moon and beyond.

FOOTNOTES

1. Much of the material in Section 7 and 8 of this report has been adapted from Donald D. Baals and William R. Corliss, Wind Tunnels of NASA (Washington, D.C.: National Aeronautics and Space Administration, 1981), pp. 25-8.

4. George W. Gray, Frontiers of Flight: The Story of NACA Research (New York: Alfred A. Knopf, 1948). pp. 42-43.

BIBLIOGRAPHY

Anderton, David A. Sixty Years of Aeronautical Research: 1917-1977. Washington, D.C.: National Aeronautics and Space Administration, 1978.

Anderson, John D. Jr. Introduction to Flight: Its Engineering and History. New York: McGraw Hill Book Company, 1978.

Baals, Donald D., and Corliss, William R. Wind Tunnels of NASA. Washington, D.C.: National Aeronautics and Space Administration, 1981.

Berkes, John D. The High Speed Frontier. Washington, D.C.: National Aeronautics and Space Administration, 1981.

Gray, George W. Frontiers of Flight: The Story of NACA Research. New York: Alfred E. Knopf, 1948.

PHOTOGRAPHS

(click on the above photographs for a more detailed view)

Top

Top

Last Modified: Mon, Jan 8 2001 10:00:00 am PDT

http://www.cr.nps.gov/history/online_books/butowsky4/space3.htm

![]()