Since 1995, the National Park Service (NPS) has partnered with the National Aeronautics and Space Administration (NASA) to document many of the historic resources related to our Nation's space program. Recently, they teamed up to record the nation's Space Transportation System, known popularly as the Space Shuttle. This cooperation took on special importance after the Atlantis--the last shuttle to fly into space--returned to earth in 2011 and was retired. Directed by the lead architect Thomas Behrens, documentation teams completed a comprehensive set of drawings and associated documentation that describes in detail various components of the shuttle system. The NPS' Historic American Engineering Record (HAER) has produced measured and interpretive drawings, written histories, and large-format photographs that are now available through the Library of Congress. Accurate 3-D digital models, built to produce measured drawings are now available online as fly-through videos. As a result of this partnership, a fascinating part of our space program has been recorded for research and posterity.

"How we, as a nation, were able to grow our space program from small, single-engine rocket boosters to the complex systems and assemblies required for lunar journeys, and then create a fleet of reusable manned spacecraft to construct and supply the space station is a story as multifaceted and complex as the space shuttles themselves," says Jennifer Groman, NASA's Preservation Officer. Behrens' teams tell this story.

In 1961, President Kennedy issued a challenge to NASA and the nation to "achieve the goal, before the decade is out, of landing a man on the moon and returning him safely to the earth." In the same year, a Redstone rocket launched Mercury Program Space Capsule Freedom 7 carrying Alan Shepard, the first American astronaut, into sub-orbital space.

Just eight years later, NASA launched Apollo 11, carrying astronauts Neil Armstrong, Michael Collins and Buzz Aldrin, with equipment and vehicles for a lunar landing. In the decade that followed, NASA developed the space shuttle program - a fleet of reusable manned space vehicles designed for multiple flights into orbit and runway landings. In 1981, the shuttle Columbia (followed by the Challenger, Discovery, Atlantis, and Endeavor) made the first of 135 successful space shuttle missions.

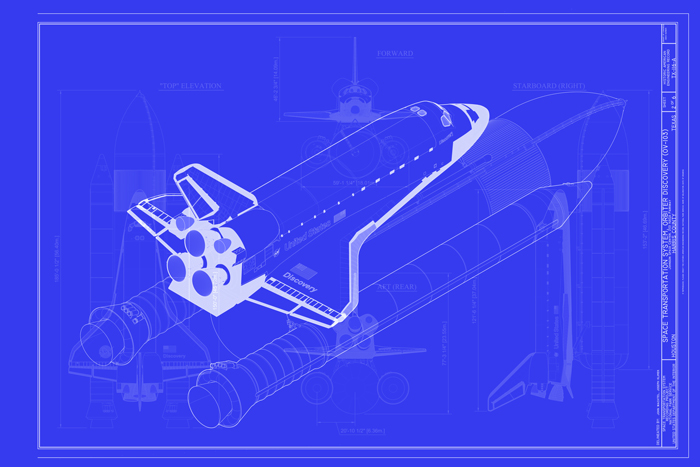

A space shuttle launch represented the accumulated knowledge and work of tens of thousands of men and women. As it awaited lift-off on the launch pad, the shuttle consisted of four major systems, the orbiter, the main engines, the external fuel tank and the solid rocket boosters. Each contained sub-assemblies of hardware, software, sensors and controllers all communicating with one another and with main computers, updating information in fractions of a second. Behrens' teams documented examples of all four systems.

NASA's research and development teams were driven by the urgency of the Cold War and the space race. Under the direction of NASA scientists and engineers, private contractors fabricated shuttle components and assemblies out of new materials and innovative methods. Everyone strove to get every detail right; once launched, there could be no second chances to redesign a system. Instead of incrementally designing systems, NASA engineers shifted to concurrently designing components. Private companies that were supplying assemblies, large and small, had to ensure their pieces of the mechanical puzzle mated flawlessly with bigger systems and performed as designed.

Documenting the Space Transportation System

The HAER teams set out to capture and record the full complexity of the Space Transportation System, a task that involved numerous historians and documentation specialists over a course of a dozen or more trips to important NASA locations, including the Kennedy Space Center at Cape Canaveral, Florida; Johnson Space Center, outside of Houston, Texas; and the Marshall Space Flight Center in Huntsville, Alabama. The teams also traveled to the Santa Susana Field Laboratory near Canoga Park, California, to document facilities where the rocket engines were developed and tested.

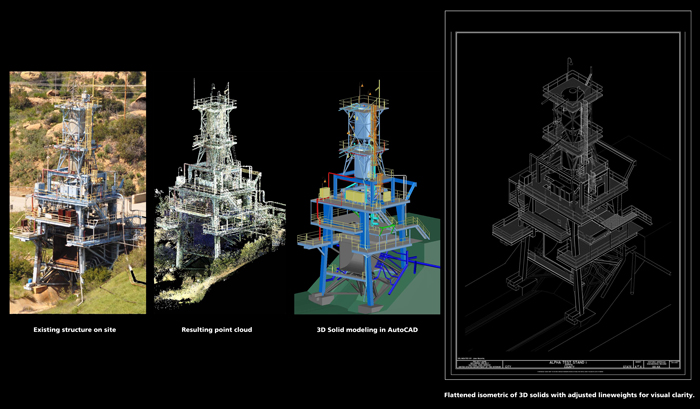

At each location, HAER teams employed sophisticated tools to accurately capture the forms, features and functions of these structures. The documentation teams used high-definition laser scanners to capture "digital point clouds," files that are composed of millions of coordinate points that can be manipulated in computers to construct three-dimensional models. Combined with meticulous field measurements and photogrammetry, technicians created several layers of documentation to reflect the system's complexity.

Documenting the Shuttle Assembly

The HAER teams documented an example of the full shuttle assembly – the orbiter Discovery, main engines, external tank, and boosters as a single unit, and then examined each component separately. It is one of the most complex pieces of machinery ever created by humans, and each component has a unique history and development.

One team explored every inch of the Discovery while it was at the Kennedy Space Center, and was also on hand to welcome the orbiter to its new home at the Smithsonian's Udvar-Hazy Center in Dulles, Virginia.

"Getting up close and personal with the Discovery during its process of being decommissioned was a privilege and an opportunity of a lifetime," said HAER team member John Wachtel. "I couldn't believe that I was touching something that had been to space and back! Meeting men and women who maintained the Shuttle Fleet as they were working on Discovery for the last time was also a privilege. The high degree of dedication and devotion to their jobs and the mission remained evident, even in the closing months of the program."

The HAER team took a different approach to documenting the external tank, solid rocket boosters, and main engines. The external tanks disintegrate after their jettison and re-entry into earth's atmosphere, and the main engines and boosters are so intricate that any scanning or hand-held measuring device was inefficient. Instead of scanning and measuring the actual machinery, Behrens and his teams relied on technical specifications and diagrams shared by NASA headquarters to create models and drawings for them.

Documenting the Test Stands

Some of the most visually striking components of the space program are the propulsion test stands designed to hold rocket engines in place while measuring performance. The stands had to withstand the tremendous power, heat, noise, and vibrations produced by the assemblies being tested. Many of the test stands built for the Apollo Program were repurposed and adapted for the development and testing of the space shuttle main engines and their improved variants.

To support concurrent development of assembly systems, test stands were built at several locations across the country. HAER teams documented test stands at the Marshall Space Flight Center at Huntsville, Alabama, and the Santa Susana Field Laboratory in Canoga Park, California. At the start of the project several of the test stands at Santa Susana were still in configurations from the shuttle main engine testing era. "I was stunned by the scale of the site," said Behrens. "This was a vast complex with multiple test areas scattered throughout very rugged terrain, three of which had several extant test stands, and each was configured to a unique purpose."

The HAER team created measured and interpretive drawings of the test stands from 3-D digital models derived from laser scan data and field measurements. The models helped the team document complicated features and processes in a way that is understandable to nonspecialists.

In engineering fields, and especially aerospace engineering, there is little room for individual expression. Occasionally, however, pride of workmanship appears. A HAER team found an unusual signed example of workmanship at the Bravo Test stand at the Santa Susana Field Laboratory. A skilled welder sculpted from molten welding alloy a hand with a finger pointing to a beautifully crafted weld, and signed the name, "Floyd." Visitors, reaching out to touch Floyd's handiwork, have burnished the hand to a high polish. Behrens said, "It's like finding a rare gem. When someone takes the time to sign their work, the work becomes more like a sculpture."

He continued, "A challenge that we have at the engineering record is that much of what we document is dehumanized machinery, built at a larger-than-human scale. The test stands can be 10 to 20 stories tall. It is exciting for us when you find signs of individual workmanship, because then the machinery becomes more human. Someone's pride in their craftsmanship creates a human connection, and reminds us that individual men and women built the space program."

The accomplishments of NASA's space program have been well documented; however the actual space craft and test facilities that were critical to achieving these unique successes are somewhat ephemeral and are being lost at an alarming rate. As retired Marshall Space Flight Center Historic Preservation Officer, Ralph Allen recalls, "Over twenty years ago, NASA and the Historic American Engineering Record entered into a long term partnership to document these national treasures for future generations. Ranging from test stands that were used to ensure that our space craft were safe to an actual space shuttle HAER has undertaken the difficult task of understanding and interpreting some of the most complicated structures and systems ever imagined and built by man." Allen continued, "Mr. Behrens' leadership, knowledge and advocacy enabled his teams to produce drawings, photographs and historical records that capture the essence and story of America's quest for space. The NPS is fortunate to have employees of such high calibre and dedication."

The measured and interpretive drawings, written histories and large-format photographs will become part of permanent HABS/HAER/HALS Collection at the Library of Congress. By using advanced digital hardware and software, the NPS HAER program has been able to effectively document sites and features, to deliver rich digital content and, most importantly, create a permanent, archival record. The documentation from the Space Shuttle and Test Stand projects will join documentation from sites as grand as the Statue of Liberty and the Golden Gate Bridge and as humble as a cotton-bale press in Natchitoches, Louisiana. This collection is available online to present-day researchers, enthusiasts and anyone with an internet connection to use and reproduce without copyright restrictions.

To date the Historic American Engineering Record has documented over fifty significant sites and features associated with our ventures into space, producing more than 162 measured and interpretive drawings, nearly 700 large-format photographs and over 350 pages of written history, with more to come. It is a fitting tribute to the achievements of the men and women who worked on the Space Transportation System.

For more information contact Thomas Behrens

Acknowledgements - Thanks to Karen Mudar who commeted on earlier versions of this article