|

The protection and preservation of a precious and valuable resource was utmost in the mind of Sylvester Baxter when he sought to convince influential Bostonians to lend their support to have the Casa Grande ruins preserved for the future. It was through the efforts of these people that the first preservation and protection measures were taken in 1891. This early stabilization work, combined with future endeavors, has attempted to stop natural deterioration and repair damage. Although it has frequently proved to be a maze of dead ends, the preservation objective has remained a vital part of the monument management. The construction of shelter roofs over the Great House, combined with major stabilization efforts in 1906-08, 1924-28, 1955-56, and 1967, has slowed natural deterioration. Besides these endeavors, experimentation with chemical preservatives occurred in the 1930s, 1940s, 1970s, and 1980s in an attempt to harden the earthen remains against erosion. The solution used up until 2001 in this ongoing effort for stabilization was a commercial cement binder product called Daraweld-C to produce "Amended Mud" which was coated on the remains by using whisk brooms. Today's Amended Mud includes Rhoplex E-330, which is an acrylic polymer often added to Portland cement. Frank Pinkley, the Ruins first resident custodian, began in 1918 to give some thought to a means by which the exposed walls could be protected. He wrote to National Park Service Director Stephen Mather that he had considered spraying the walls with silicate of soda, but he did not do so. Despite his concerns, Pinkley received no preservation money until the 1925 fiscal year which began July 1, 1924. Preservation work continued until February 1928 with the initial goal to stop wall sapping. Following that work, a concrete cap was placed on the walls as a means to prevent crumbling of the soil. When Thomas Vint visited Casa Grande toward the end of 1930, he and Pinkley discussed ruin preservation techniques. Pinkley decided that he did not like coating walls with concrete. He found it objectionable because it hid the walls. Consequently, Pinkley and Vint talked about the possibility of using some transparent waterproofing chemical to coat and harden the ruin walls. Toward the end of January 1931, Vint wrote to Pinkley to tell him that he had obtained a gallon of a product called Dehydratine which was manufactured by the A. C. Horn Company. Vint's action evidently caused Pinkley to decide that it was time to more actively seek a chemical preservative. Pinkley replied that he would test the product on the ruins. At the same time, Pinkley sought more information on the subject of waterproofing materials. He wrote to the Bureau of Standards in Washington, D.C. to request a copy of "A Preliminary Report of Exposure Tests on Colorless Waterproofing Materials" published in 1921. Pinkley evidently took one further step to obtain chemical preservatives. In early February 1931, a National Park Service article titled "Solution to Preserve old Masonry is sought" appeared in newspapers almost nationwide. This appeal brought letters from companies in such states as New York, Michigan, Ohio, California, and Arizona with offers to send test samples. The newspaper article resulted in a flood of chemical preservatives being sent to the monument. When tested on small wall areas, none gave satisfactory results. The Horn Company product Dehydratine #2 turned dark. A liquid "Ankerite", received from the Lucille Chemical Company of Glendale, California, was not quite colorless and it gave the test area a glossy appearance. After four months, it cracked. Product samples continued to arrive at Casa Grande from 1931 into 1934. This parade of products carried such names as Amoglaze, Inwood, Stucco Waterproofing Compound, Oronite Waterproofing, Hornstone Crystals, Forex, Unicrete, Permo #4, and PeneTex. Some companies sent representatives with samples to apply on test areas. In November 1932 an agent of the Air-Spray Company of Washington, D.C. applied two test applications of his material on eighteen small wall areas. By January 1933 the product had cracked and in March of that year it began to peel from the wall.

In 1933, the Engineering Section of the National Park Service field office in San Francisco obtained some Civil Works Administration money to use for experiments with caliche and adobe preservatives. That office made an arrangement with Stanford University for laboratory space in which to conduct the work. F. A. Kittredge contacted Southwestern Monuments Superintendent Pinkley and asked that he send 100 adobe brick made from Casa Grande soil so that the waterproofing experiments could begin. He proposed to first perform a physical and chemical analysis of the adobe soil so that a determination could be made if a potential preservative would cause a chemical reaction with the soil. Kittredge hoped to find a colorless waterproofing fluid that would not peel or crack. In addition he sought to design a concrete cap which would keep wall tops dry. Pinkley had Casa Grande Custodian Palmer send ninety-seven adobe brick to Kittredge. Palmer evidently had no objection to turning over the preservative testing to the San Francisco field office. At the same time, however, he wanted to make sure that the new Park Service laboratory received a sample of his favorite waterproofing chemical. Within days of sending the adobe to Kittredge, Palmer wrote to M. J. Cavalier of the Truscon Steel Company in Phoenix and asked that he send a sample of PeneTex to be tested. In addition to Palmer's help, Kittredge asked companies that produced chemical preservatives to send samples of their products to the engineering laboratory. By March 28, 1934, fifty-two different preservatives had been received. Of that number, forty-three had been tested by August 18, 1934. Kittredge felt that only one of the forty-three chemicals had proved worthwhile. That solution, named Por-Lox, came from the Truscon Laboratories. His assessment, however, proved premature. By early March 1935 Por-Lox failed an ultra-violet test.

NPS Historical Photograph Collection at Casa Grande Ruins When all the commercial preservatives failed to pass National Park Service tests, the field office engineering staff set out to develop its own product. Frederick Martius began with celluloid solutions, but any mixture over one percent proved glossy, and glossy material would not penetrate. Soon, however, Martius produced a colorless chemical that did not gloss but penetrated and was not affected by ultra-violet rays. He called this vinyl resin in acetone and toluene solution NPSX. On March 20, 1935, field work began at Casa Grande with that chemical. He covered several test areas in the southwest corner of Compound A with two coats of two, three, three and one-half, and five percent NPSX solutions. NPSX worked for two years, but when it was examined in 1938, in the third year, it failed to repel water. In fact the NPSX-treated areas absorbed as much moisture as the untreated walls. These results were very disappointing because NPSX cost too much to apply every two years. Consequently, it was back to the 1931 starting point to find a means to preserve the ruin walls. In mid-1939, frustrated with watching the old cement plaster scale off the rapidly deteriorating ruin walls, the Casa Grande Custodian A. T. Bicknell decided to experiment with "bitudobe." At the time, the Civilian Conservation Corps work force used this product to cover the exterior of the adobe buildings being constructed at Casa Grande. On June 27 Bicknell had two small wall sections of the Clan House coated with bitudobe. After a month it seemed to be effective. As a result, the custodian sought official approval to put bitudobe on all standing ruin walls. The value of bitudobe was never determined, however, because no funds were available to purchase it. At that point Bicknell settled for stabilizing ruin floors by using a caliche base with a top dressing of bitumuls oil. The CCC workers employed on that project had all the floors covered by September. Although the 1930s tests failed, Casa Grande and Southwestern Monuments personnel could not give up on chemical preservatives. Charlie Steen seemed determined to find some liquid that would work. In the spring of 1940, he removed the concrete cap from the east half of the Clan House. Then he dug trenches beside and under those walls in which he placed a six-inch curtain of caliche waterproofed with emulsified asphalt. As the final step he sprayed the wall area with two coats of "Themec" which was an emulsified cement paint. In a month the Themec turned lavender and in a year it had cracked and peeled. Lack of money and a labor shortage prevented further preservation activity until after the Second World War. Although he had read about the earlier experiments with chemical preservatives and had done some testing himself, Charlie Steen still hoped to succeed where others had failed. He decided to perform more tests with water-repellent products. In these experiments to find an adequate preservative, Steen spent October and November 1946 at Casa Grande treating caliche walls and blocks with eight commercial products. He began with test areas on the Clan House walls, but switched to caliche blocks which he obtained from the nearby prehistoric Adamsville site. Of the eight water-repellent chemicals, Ethyl Silicate seemed the most promising. It, however, had no long-lasting effect. One product, Sodium Silicate, which had been suggested by Frank Pinkley in 1918, failed. Of the other substances, Diamond Seal resisted water for only several minutes. PeneTex, Hilding Palmer's favorite from the previous decade, separated with its oil being absorbed but not the wax portion. The kerosene-based wax substance, Dehydratine 2a, left a dark stain without soaking into the soil. Paraffin, a wax mixed with white gasoline, did penetrate two inches. Emulsified Asphalt did not work because of the high salt content in the caliche. Steen merely listed the last product, Synasol, without comment. Since the 1930s experiments with chemical preservatives had involved only surface applications, Steen decided to use other methods on the Adamsville caliche blocks. He tried to drill holes in the caliche, but frequently the blocks would break when the drill encountered a pebble. Absorption in holes, however, was hardly greater than with surface treatment. A capillary action test failed from lack of absorption. Steen tried to force liquid into the blocks under low pressure, but this attempt failed "miserably." Placing a block in a liquid in an effort to have complete saturation only caused the block to become soft and weak. Like his predecessors, Steen had to concede defeat. In any case, sealing the walls with a waterproofing agent could only promote greater damage to them if the capillary action of ground water could not be controlled. In 1954 John Davis, the General Superintendent of the Southwestern Monuments, wrote to the Region Three director about an urgent need for money to stabilize the walls of Compound A and the unfinished part of Compound B. This reminder that no work had been done at Casa Grande for five years finally brought funds for stabilization in 1955. Roland Richert and Gordon Vivian worked between February 3 and March 8, 1955 on a major stabilization effort on Compound A. They had originally planned to cap and veneer the walls with caliche, but they were unable to make a suitable caliche, sand, and chat mixture that would work. Therefore, they fell back on the old concrete-stabilized soil solution. The walls were cleaned by raking away loose material, and then a new wire net was placed on them where needed to hold the cement-stabilized soil in place. The new veneer on the north building walls was sprayed with Daracone, a silicone water repellent, as an experiment. Only forty percent of Compound A had been completed when Richert and his crew left on March 9. The greatest amount of work had been done on eighteen room walls. A heavy rain on August 2, 1955, seemingly did not affect the newly stabilized area of Compound A. Superintendent Bicknell thought the area sprayed with Daracone fared better. At the Great House, however, a 338-pound piece of caliche fell from the upper part of the south wall. Bicknell hoped to have that area patched. On February 29,1956, Vivian and Richert returned to finish the stabilization work on Compound A. Working until April 3, they used the same procedures and techniques that they had used in the previous year. In addition they reinforced and patched the area from which the caliche had fallen from the Great House, and sprayed it with Daracone. Funds to stabilize the walls of Compound B were approved for 1958. Consequently, Vivian and Richert returned between April 16 and May 19 to attend to those enclosure walls. On this occasion, Vivian and Richert decided that, since the thin, concrete wall veneer had never really worked, they would try to preserve these walls by enclosing them within new walls. These new walls would only cover the old ones, so that the new material would not have to bond with the old wall surface or be dependent on the prehistoric walls for support. To accomplish this task, they dug a twelve-to eighteen-inch-deep trench on each side of the compound walls to permit forms to be placed two inches away from the base of the walls. Vivian and Richert then filled the forms with a concrete-caliche mixture and tamped it to a height about two inches below the top of the prehistoric walls. The caliche came from a Coolidge Sand and Rock Company pit about five miles east of the monument. After the forms were removed, they sprayed the new walls with Daracone. The impression marks left by the forms were not removed from the new walls until 1972. Archeologist Gordon Vivian could not help but try one more chemical preservative experiment. On October 2 and 3, 1963, he sprayed thirty-four gallons of Texas Refining Company sand and adobe preservative on both sides of the largest east-west wall of Compound B. This epoxy solution darkened the wall and formed a glaze which continued to look wet although it had set up very hard.

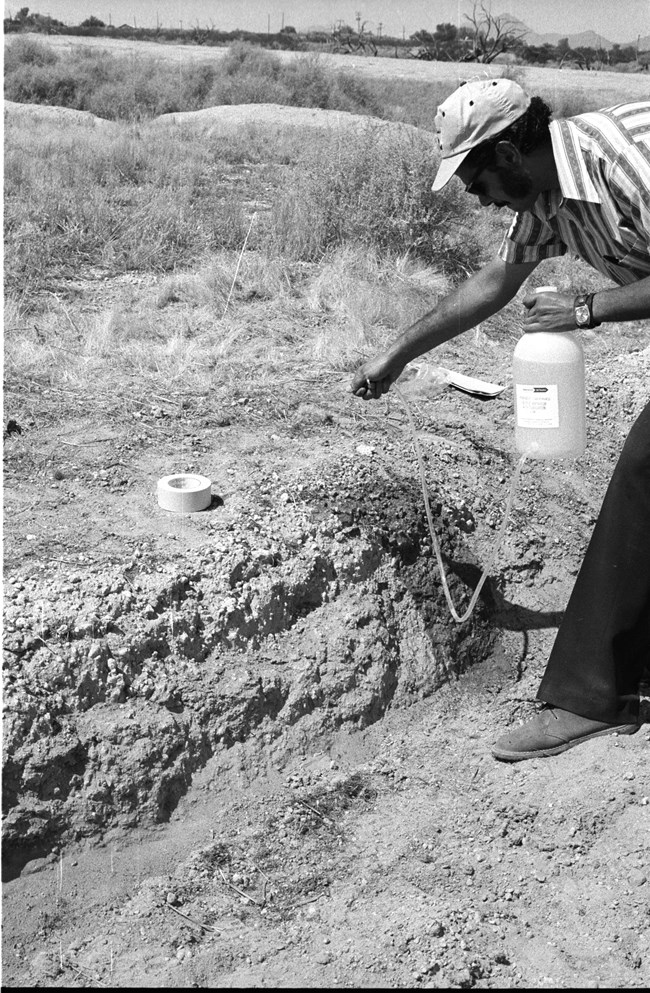

NPS A major stabilization project focused on Compound A between March 6 and April 28, 1967 with some work done on Compound B. Martin Mayer performed maintenance work on all walls and buildings including the Great House. He either patched and/or replaced disintegrated soil cement caps and veneer on all walls and treated them with silicone. In the Great House, Mayer plastered the lintels over seven doorways, replastered loose and missing concrete stucco on the building's base, and repaired minor breaks and holes in walls. A new product, Daraweld-C, was mixed with the soil-cement to help new patches bond better. In Compound B Mayer sprayed silicone on the compound walls and stabilized rooms 3 and 4. W. E. Sudderth came to Casa Grande between May 16 and June 8, 1972 to continue the never-ending stabilization work. He patched cracks in the compound walls and a number of the rooms of Compound A. In addition Sudderth put a number of test finishes on walls to find the one that would be most in harmony with the Great House for uniformity of color and texture. He was instructed to apply the finish judged to be best to the walls of both Compounds A and B. He decided that a commercial product called Daraweld-C proved to be the most satisfactory. Daraweld-C was mixed with caliche and sand to produce an "Amended Mud" which was then applied to the ruins walls with whisk brooms. It was found that a coating of this brownish-colored substance allowed the capillary moisture in the walls to evaporate. The only disadvantage to Amended Mud was that it had to be applied every two years. In the mid 1970s a three phase chemical research plan was developed by the Western Archeological Center. It was intended that the first two phases would involve the testing of chemical soil amendments to find one that would effectively protect badly eroded walls and the development of a durable overcoat mortar for soil cement walls which would give a more natural appearance. Twenty-eight test walls were constructed at Casa Grande from soil taken from the prehistoric Escalante Ruins. These walls were allowed to weather for nine months between March 1977 and January 1978 before they were treated with ten water-based chemicals. The effectiveness of these chemicals was monitored over a twelve-month period. They evidently were not found to provide protection. No overcoat mortar was tested. Phase three of the chemical testing on the experimental walls came about through a contract with the Arizona State University College of Engineering. Its purpose was to determine the effectiveness of electro-chemical treatment of earthen walls in terms of compressive strength, decreased capillary action, appearance, and weathering. The Arizona State engineers recommended the use of aluminum sulfate for an electro-chemical treatment. It increased the compressive strength and reduced capillary action. Thus, walls were subject to less weathering. This remedy also had less effect on wall color than other treatments. Again no action was taken to implement the study's recommendation. A plan surfaced in early 1986 to remove the old concrete plaster from the Compound A walls and merely cover the walls with Amended Mud. Believing that all of the preservation treatments over the years, with the possible exception of Amended Mud, might have weakened the prehistoric caliche walls, Dennis Fenn, of the Western Archeological Center, recommended that the concrete plaster not be removed. He thought that to do so might cause irreversible damage to the original material. As a result, a decision was made to continue to apply the Amended Mud coating every two years with annual applications as needed. Experiments to cover the prehistoric caliche walls with concrete and chemical preservatives failed to adequately preserve them. On some occasions, these measures damaged the walls resulting in the loss of prehistoric material. Probably the best preservation technique, as advocated in 1902 by S. J. Holsinger, would have been the use of caliche for repairs. |

Last updated: February 24, 2015