Last updated: May 23, 2023

Article

Fort Livingston, Grand Terre Island

Prepared by Carol S. Chin and Jason Church

5 November 2010

Executive Summary

NCPTT made a second visit to Fort Livingston, Grand Terre Island, in September, 2010. Eight surface washing agents were tested for their effectiveness in removing weathered crude oil from the brick masonry at the fort. A few of the products tested were somewhat effective, removing approximately 50% to 70% of the surface soiling from the brick surface. None of the products tested to date provided excellent results, similar to pre-oiling conditions.

A clay poultice was also tested as a method of applying a solvent cleaner. The poultice appeared to be as effective as the best surface washing agent. Poultices provide a longer time for the cleaning product to react with and break down the oil, so the results of this test indicate that dwell time is important in removing weathered crude oil.

Performance-based contracting is recommended for cleaning of the weathered crude oil from Fort Livingston, with proposals from potential contractors guided by a pre-defined set of end criteria. It is very important that an architectural conservator with experience in masonry conservation be part of the contractor’s team and be on site to supervise clean-up operations.

Introduction

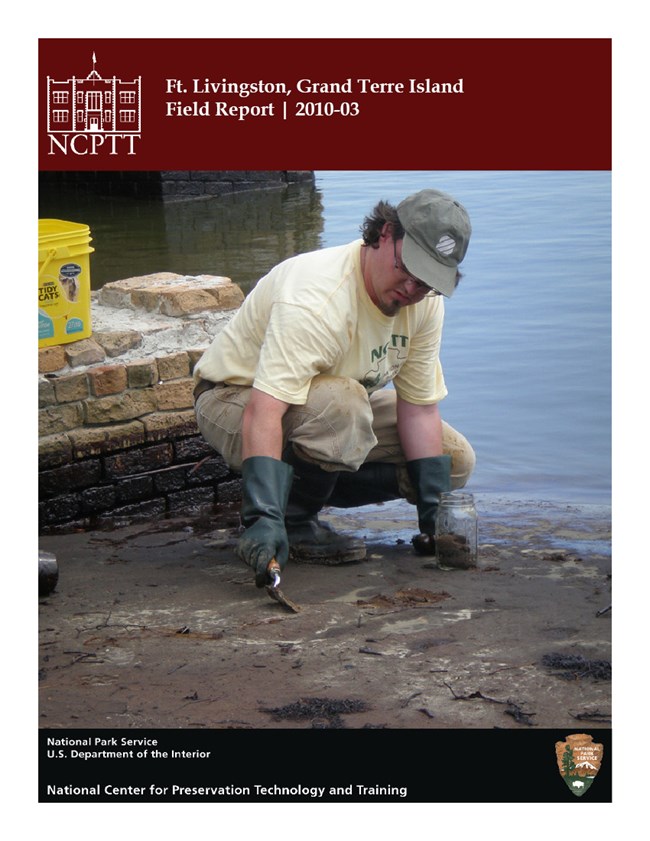

NCPTT staff made a second visit to Fort Livingston, Grand Terre Island, on September 9 and 10, 2010 at the request of the Unified Area Command (UAC). The NCPTT team included Carol Chin, Jason Church, Ed FitzGerald, and Payal Vora (from the University of Texas, Austin.) The purpose of the visit was to document any changes in condition since the visit on June 16, 2010, to evaluate the condition of the previous test areas, and to perform additional field cleaning tests. As a result of these evaluations, further recommendations are presented at the end of this document.

On September 9, NCPTT staff were joined by NPS archeologist Paul Gleeson, anthropologist Liz Williams, and Louisiana SHPO representative Melissa Braud. An impending thunder storm prevented the group from remaining on Grand Terre Island past about 4pm. The next morning Chin, Church, FitzGerald and Vora returned to Fort Livingston to continue with field tests.

Changes in Condition

Additional contamination of the fort was not observed during the September 9-10 visit. While additional oil might have arrived at Grand Terre Island, there were no new areas of the fort that experienced oiling. The primary change in condition was a change in the properties of the oil itself. With weathering, the oil has continued to lose volatiles. In shaded areas and interior spaces of the fort, the oil had become sticky and more tar-like in consistency. Where the oil was also exposed to sunlight, it had become even more viscous with a dry, cracked, almost crusty surface.

Condition of Previous Test Surfaces

Previously cleaned surfaces were relatively small and appeared to be re-contaminated, as shown in Figure 1. These surfaces did not appear to be more resistant to further oiling. One of the previously cleaned surfaces was only partially re-contaminated. The portion of the surface that was not re-contaminated retained a clean and mostly non-oily appearance.

Field Cleaning Tests

Types of surface washing agents tested

Two types of surface washing agents were tested: surfactant-based cleaners and solvent-based cleaners. The cleaners were chosen based on their availability to remove oil as well as their physical properties such as pH, composition, handling precautions, and toxicity. Cleaners were applied directly to the masonry surface. Additionally, a poultice was used for one cleaning method (see below).

NCP Product Schedule

Of the products used during this site visit, De-Solv-It (Orange-Sol Blending and Packaging, Inc.) and Simple Green (Sunshine Makers, Inc.) were chosen from the National Contingency Plan Product Schedule (NCP Product Schedule), published by the Environmental Protection Agency (EPA). The products were classified as “surface washing agents” (SWA), which are defined by the EPA as “any product that removes oil from solid surfaces, such as beaches and rocks, through a detergency mechanism and does not involve dispersing or solubilizing the oil into the water column.”

| Product | Manufacturer | Website |

|---|---|---|

| Biz | Procter & Gamble | http://www.bizstainfighter.com/ |

| Dawn | Procter & Gamble | http://www.dawn?dish.com |

| De-Solv-It | Orange-Sol Household Products, Inc. | http://www.orange?sol.com |

| Goo Gone | Magic American Products | http://www.magicamerican.com |

| LA’s Totally Awesome | Awesome Products, Inc. | http://www.lastotallyawesome.com |

| Simple Green | Sunshine Makers, Inc. | http://www.simplegreen.com |

| VeruSOLVE | VeruTEK | http://www.verutek.com |

| Vulpex | Picreator Enterprises, Ltd. | http://www.picreator.co.uk |

Application

Surface Washing Agents

The SWA was applied by spraying directly onto the surface, allowed to dwell on the surface for 60 seconds, re-applied, and agitated for 120 seconds using a soft-bristle brush. Additional cleaner was applied during agitation to insure that the surface did not dry. Excess SWA and rinse water was collected for disposal using pet training pads.

Poultice

The poultice was prepared from attapulgite clay mixed with mineral spirits to the consistency of peanut butter. The mixture was spread on two small areas, one that had been cleaned previously and another that had not been cleaned. Both areas were covered lightly with a plastic bag to keep the mixture from drying too quickly. After several hours, the plastic was removed to allow the clay to finish drying. Once the poultice appeared dry (lighter in color and cracked) it was brushed off the surface of the brick. The dried, soiled poultice was collected for disposal.

Results

Effectiveness of SWAs was not evaluated quantitatively with instrumentation and was subject to interpretation. All ranking was done through visual inspection on site by the staff doing the cleaning tests. The results of the cleaning tests were ranked best to worst by the definitions: poor, fair, good, and excellent, as follows:

Poor: A Poor result was a cleaning patch where very little of the surface oil was removed. Usually no visual oil was removed on the application of the cleaner and only a slight amount was removed during agitation. In most cases it is likely that the oil was removed as much by the agitation as by the cleaner.

Fair: A Fair result was a cleaning patch where some of the surface oil was removed but a portion of the surface coating of oil remained and oil was still evident in the cracks and crevices. In a Fair rating oil was visibly removed during the initial application of the cleaner but not without agitation. The surface retained a soiled appearance.

Good: A Good result was a cleaning patch where the majority of the surface oil and a majority of the oil in the cracks and crevices were removed. In a Good rating visible oil was removed during the initial application of the cleaner. It was evident that the surface tension of the oil was broken by the spray application of the cleaner and breakdown of the oil began before agitation.

Excellent: An Excellent result was a cleaning patch where all of the surface oil and a majority of the oil contained in the cracks and crevices were removed. In an Excellent rating visible oil was removed during the initial application of the cleaner. It was evident that the surface tension of the oil was broken by the spray application of the cleaner and breakdown of oil began before agitation and minimal to no agitation was needed to cause the cleaning action. No Excellent cleaners were found in this phase of testing.

Most of the surface washing agents appeared to dislodge some of the oil, based on darkening of the product during agitation. The results based on changes in the appearance of the masonry surface were insignificant except for three of the products: Goo Gone, LA’s Totally Awesome, and Vulpex.

The poultice application method was also effective, presumably because of the longer time that this method provides for the product to react with the oil. Dwell time for this test application was four hours. It appeared that the poultice applied to the surfactant-cleaned surface did not perform as well as the poultice applied to the untreated surface. It is possible that the process of cleaning with the surfactant caused some of the oil to penetrate farther into the surface of the brick, making this contamination less accessible for removal by the poultice application. Alternatively, residual surfactant or moisture might have prevented the poultice from adhering to the remaining oil on the treated patch.

Although this test used a dwell time of four hours, typical dwell times for a poultice are 24 hours; therefore this method has the potential to be much more effective than was observed during these tests. Mineral spirits were used for this test, but because a poultice is a delivery method, it could also be used to apply a surfactant or a different solvent. The results are summarized in Table 2, below.

Table 2. Results of cleaning tests at Fort Livingston, September 2010.

| Product | Manufacturer | Diulted/Mixed | Type | Results | Notes |

|---|---|---|---|---|---|

| Biz | Procter & Gamble | mixed with water | dry (granular) surfactant | Poor results | Dry product was mixed into a paste and applied. Product was not dissolved and conAnued to absorb moisture so that it adhered to the surface. |

| Dawn | Procter & Gamble | diluted 1:1 with water | surfactant | Poor results | |

| LA’s Totally Awesome | Awesome Products, Inc. | diluted 1:50 with water | surfactant | Fair results; removed approximately 50% of the surface soiling. | |

| LA’s Totally Awesome | Awesome Products, Inc. | neat | surfactant | Fair results | Results were similar to the diluted product. |

| Simple Green | Sunshine Makers, Inc. | neat | surfactant | Poor results | |

| VeruSOLVE | VeruTEK | neat | surfactant | Poor results | standard dwell time |

| VeruSOLVE | VeruTEK | neat | surfactant | Poor results; slightly better results than two minute dwell time. | 20 minute dwell time |

| Vulpex | Picreator Enterprises, Ltd. | diluted 4:3 with mineral spirits | surfactant/solvent | Fair results; removed approximately 50% of the surface soiling. | Not evident whether effectiveness was due to the Vulpex or the mineral spirits. Greater dilution of Vulpex might have been better. |

| De?Solv?It | Orange?Sol Household Products, Inc. | neat | solvent | Poor results | Affected the outer surface of the oil, but removal from the masonry surface was only about 10%. |

| Goo Gone | Magic American Products | neat | solvent | Good results; removed approximately 70% of the surface soiling. | Some surface soiling and staining remained. |

| Except where noted, tests were carried out by applying the SWA, allowing 1 min. dwell time, reapplying SWA, agitating 2 minutes, then rinsing with water. | |||||

Collection of Samples

Oil

Samples of oil, which had the consistency of soft tar, were collected from the surface of the sand in the southwestern casemate. The oil had weathered and “dried” considerably since the June 16, 2010 visit. Eight quart-size jars and two pint-size jars of oil were collected. Samples of oil were also collected from the granite steps on the southwest side of the fort. Some of the oil from the steps had baked in the sun and been wet and dried so many times by the tides that the surface appeared dry and cracked (Figure 2.), requiring that it be removed by using a plastic scraper. Oil that had dried in a shaded portion of the granite steps had a stickier surface that did not appear dry and cracked. This oil also required a scraper for removal because it was not as warm (and therefore not as soft) as the drier oil that had been warmed in the sun, decreasing its viscosity slightly.

Oiled shells

Oiled shells were collected near the fort (several shells in a pint-size jar) and from the shoreline to the east of the fort (two quart-size jars). These samples were collected for additional research in the laboratory.

Sand

Sand was collected from just above the high water line near the shoreline east of the fort. In this area sand crabs had dug up darker colored sand that was believed to be slightly contaminated sand from below clean surface sand. It is likely that surge during storms Alex and Bonnie deposited clean sand on top of oiled sand along the shoreline of Grand Terre Island.

Recommendations

Conditions

Differences in the appearance of the oil as well as the results of the cleaning tests indicate that the oil has weathered into a sticky coating on the surface of the masonry of the fort, making it much more difficult to remove at this later date compared with initial cleaning tests performed in June 2010. The solvent-based cleaner “Goo Gone” and the clay poultice delivery method were most effective at removing the tarry oil. Goo Gone is a solvent-based cleaner, and the clay poultice was mixed with mineral spirits, so this suggests that a solvent is an important component that helps “soften” the oil for more effective removal.

Approach

Because of the level of work that will be necessary to remove the weathered crude oil from Fort Livingston, an architectural firm or contractor with specialization in historic preservation is needed. Performance-based contracting is recommended. A set of end criteria may be defined, then potential contractors could be asked to provide creative, innovative solutions to the oil removal problem at hand. NCPTT recommends that contractors be pre-qualified to bid on the oil removal based on their previous historic preservation experience. The Unified Area Command could put together a panel of technical experts to review cleaning proposals and recommend the best approach. Performance-based contracting has been used by the U.S. Army and the U.S. Army Corp of Engineers on cultural resource preservation and restoration projects such as preservation of the Tomb of the Unknowns at Arlington National Cemetery. It is further recommended that an architectural conservator with experience in masonry conservation be part of the contractor’s team and be on site to supervise clean-up operations.

Selection of a Contractor

NCPTT recommends that the contractor and sub-contractors must meet the following: Adherence to the professional standards set forth in the American Institute for Conservation Code of Ethics and Guidelines for Practice, and the Secretary of the Interior’s Historic Preservation Professional Qualification Standard for Conservator. The contractor shall review credentials and portfolios of prospective project members. Conservators shall be professionally trained in the conservation of works of brick masonry, or similar specialty directly applicable to the conservation for Fort Livingston. All conservator positions require at minimum a Masters in Conservation from an American or Canadian certified graduate program as recognized by the U.S. Govt. Dept of Education and 3 years experience in the field of conservation. Technicians would require a Bachelor of Arts Degree and 2 years experience.

Selection of Cleaners

While solvent-based cleaning products appeared to perform better in these field tests, they have some inherent disadvantages compared to surfactant-based products. Solvents have the potential to mobilize oil, possibly moving some of the oil deeper into the masonry. The farther the oil penetrates the brick, the more difficult it is to remove it. Any remaining oil has the potential to do damage as it breaks down or is degraded by microbial activity. Solvents also tend to leave a residue. This residue can also be attractive to microbes and has the potential to enhance bio-growth. Byproducts of biological activity are often acidic in nature, which can degrade historic brick and lime-based mortars.

Additional testing is required to determine the best surfactant-based product for the removal of weathered crude oil from masonry. The NCP Product Schedule is being consulted for possible products because a portion of the fort is submerged as a result of decades of erosion of the shoreline. This means that any product used to clean these areas of the fort will undoubtedly be released, at least in small amounts, to the adjacent waterways. A study of surfactant-based cleaning products is currently being conducted by Ms. Payal Vora at The University of Texas at Austin as a Master’s Thesis project. The results of this study are expected in May 2011.

Acknowledgments

The team acknowledges the excellent field assistance provided by David McKinnon and Douglas Jack who were contracted by the Vessel of Opportunity program of the Deepwater Horizon Response. Dave and Douglas kept us fed, hydrated, and even provided an additional cleaner for testing. Their assistance and good humor were very much appreciated.