|

Watering the Land: The Turbulent History of the Carlsbad Irrigation District |

|

CHAPTER FOUR

The Reorganized Company: Brief Optimism and the Final Collapse

Even though the reorganized Pecos Irrigation Company was now bereft of its long-standing access to Hagerman's checkbook, its management displayed limited optimism during the company's first years. Tansill had managed to show a small positive cash flow during the receivership period. [1] The company still owned some 30,000 acres of valley farmland with the potential for development. Except for the deteriorating Pecos River flume, the company's physical plant was thought to be in generally good condition. Company officers considered the substantial leakage from the canal network to be irrelevant since the river presumably provided a plentiful water supply. The system, however, was operating at far less than the original projected capacity: only 9,131 acres were irrigated in 1901, an increase from 7,910 acres in 1900. [2]

The Pecos Valley's economy also began a gradual improvement after the turn of the century, perhaps largely due to the completion of the Pecos Valley & Northeastern"s line to Amarillo. The new route finally gave the valley the direct market connections it had sought since the 1880s. The first carloads of Pecos Valley fruit were shipped from the Tracy farm in 1900, and the valley's other crop uncertainties began to ease. Each year, the irrigation company managed to slowly increase the number of acres it provided with water. Agricultural land values remained lower than Carlsbad's "boosters" had hoped, however. [3]

The valley's agricultural situation further stabilized with the introduction of cotton as a staple crop. Egyptian cotton was first grown locally in an experimental plot near La Huerta for the Department of Agriculture, and the results were impressive enough to induce the operators of a Texas cotton gin to relocate to Carlsbad in 1903. The valley's cotton fields displayed an immediate and relatively substantial success, and by the end of the decade cotton had become one of the valley's primary agricultural products. It remains an important local crop today. [4]

The irrigation company remained marginally profitable after its release from receivership, although the optimism of 1901 began to fade as management realized that substantial improvements to the company's physical plant would soon be necessary. By 1902, Tracy and Tansill recognized that the Pecos River flume needed immediate replacement and that any future expansion of the system hinged on a reduction of the canal network's substantial seepage problem. The magnitude of these projects suggested to Tansill that the company's investors would be better served if a buyer for the entire system could be found. Perhaps noting the legislative progress of the Reclamation Act of 1902, Tansill suggested that the United States government might be such a buyer. In late 1902, he managed to lure F. H. Newell, the chief engineer of the newly-formed United States Reclamation Service, to Carlsbad to discuss possible Federal purchase and expansion of the company's reclamation system. [5]

Meanwhile, Tracy began the task of raising the money needed to replace the wooden Pecos River flume. Hagerman's absence made this job a difficult one, but Tracy managed to gather the needed $50,000 by the early fall of 1902. The irrigation company's trying financial situation was demonstrated when the corporate directors were forced to personally guarantee repayment of a portion of the money borrowed. [6] To design the flume, the company hired Thomas Taylor Johnston, a civil engineer from Chicago. Johnston possessed experience with the U.S. Army's Engineering Corps, specializing in the hydraulics of western rivers. After his stint in the military, Johnston worked for various public works agencies in Chicago; he also designed waterworks for Memphis and Savannah, and a water power system for Seattle. [7]

The original Pecos River flume was constructed of wood, typifying nineteenth-century American canal design. By the turn of the century, however, reinforced concrete was also commonly used to construct flumes. The adaption of masonry for bridge superstructures was a revitalization of an age-old concept, dating back at least to Roman times. The development of reinforced concrete flume designs closely followed similar developments for reinforced concrete bridges, and the earliest designs for both were arch structures. Reinforcement of the concrete with iron or steel bars allowed a significant reduction in the mass of the bridge structure. Ernest L. Ransome built the first reinforced concrete arch bridge in the United States in 1889, and by the end of the century engineers were building reinforced concrete-arch bridges with spans in excess of one hundred feet. [8] Johnston's 1902 recommendations to the Pecos Irrigation Company displayed at least a basic awareness of the advantages of reinforced concrete design. He noted that "Portland cement concrete masonry with imbedded metal constitute meritorious and desirable materials of construction." [9] Compared to the construction of a steel viaduct flume, Johnston concluded that a reinforced concrete design "would be more desirable and less expensive." [10]

|

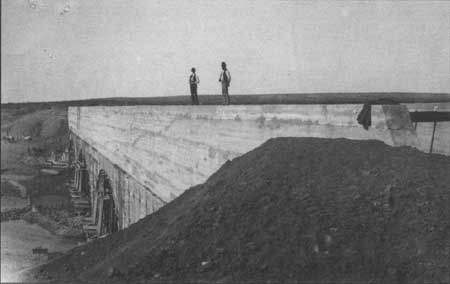

| Irrigation Company expended $50,000 in the construction of a new reinforced concrete flume in 1903. Nearly 500 fret in length, the structure was reportedly the longest irrigation flume in the United States. — Carlsbad Irrigation District, Carlsbad, New Mexico; May 1, 1903. |

In the end, Johnston's plans for the flume specified the construction of a massive reinforced concrete aqueduct some 497 feet long and up to 47 feet high. The new flume featured a water trough 18 feet high and 20 feet wide, with walls two feet thick. The trough was supported by four pairs of arches, each 25 feet high with a 100 foot span. The arch rings were 5 feet thick and sprung from grade. Piers, 8 feet thick, stood between each pair of arch rings. The 4-foot-thick floor of the trough was contiguous to the arch rings. The side walls of the flume were inset from the outer edges of the floor 6 inches on each side. Some 16,000 lineal feet of rail were placed in the floor and walls of the trough and tied across the top to carry stresses in the floor and provide lateral bracing for the walls. [11] The flume was designed to carry 1,200 cubic feet per second, even though the canal below the flume apparently carried only 365 second-feet. [12]

Construction work on the flume began in September 1902 and continued into 1903. [13] The completed structure, both massive and graceful, was a source of pride for the company and the Carlsbad community; even a representative of the Reclamation Service termed the flume "a substantial piece of work... well worth seeing." [14] On its completion, the structure was reportedly the largest irrigation flume in the United States. [15]

|

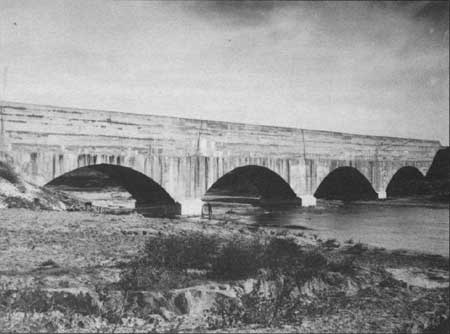

| Thomas Taylor Johnston, a former engineer with the U. S. Army Corps of Engineers, designed the impressive concrete structure to transport 1,200 cubic feet of water per second. — Natiomal Archives, Washington D.C.; October 29, 1906. |

The Final Failure

The irrigation company's perennial misfortune returned soon after the flume's construction began. Tansill's sudden death on December 27, 1902, cost the company one of its strongest advocates, although his wife assumed a portion of his former role with the company. Construction work on the new flume initially proceeded rapidly, but in 1903 Johnston suffered a serious illness and his construction foreman's wife and daughter died under "exceedingly distressing circumstances." [16] These events threw the construction project into chaos. The flume was completed sixty days behind schedule, precipitating a disastrous water shortage for the downstream farmers. [17]

Although the irrigation company's backers continued to hope for Federal acquisition of the Pecos irrigation system, the Reclamation Service's interest in New Mexico was initially drawn elsewhere. In 1903, the Reclamation Service began a careful evaluation of the possibility of constructing a reservoir and irrigation system on the Hondo River, near Roswell. This proposed "Hondo Project" was intended to irrigate some 10,000 acres of farmland, using water that was flowing into the Pecos River and, ultimately, McMillan Dam. It was not surprising, then, that Tracy and the irrigation company saw the Hondo Project as a potential threat to operations in the Carlsbad area. In June 1904, as the project seemed more and more likely, Tracy began an active campaign to protect the irrigation company's water supply by attempting to halt the Hondo Project. His first protest, a long, rambling letter addressed to the Secretary of the Interior, noted that the irrigation company relied exclusively on Hondo River water during the spring planting season. He also claimed:

|

| A young, energetic, New York banker, Francis G. Tracy moved to southern New Mexico in 1890. Ten years later, Tracy became general mamager of the irrigation project. When the United States Reclamation Service purchased the Carlsbad Project in 1905, Tracy became a vocal critic of the newly created Federal agency. — Southeastern New Mexico Historical Society of Carlsbad, New Mexico. |

It is a well-recognized rule of law in all of the arid West that the appropriator of the waters of a stream is considered likewise the appropriator of all the waters of all the tributaries of that stream. On this point I must contend on behalf of this company that it is entitled to the use of all of the flood waters of the Hondo River, at least up to such time as it finds its reservoirs full of water. [18]

Tracy's claim was given credence by the fact that the irrigation company's corporate predecessor had made an abortive attempt to construct a storage dam on the Hondo in 1892. In view of this, the Reclamation Service began an examination of Tracy's charges; this evaluation included soliciting the opinion of James J. Hagerman. Hagerman characterized Tracy's letter as a series of "amazing statements," and he noted that the irrigation company had sold Hagerman its Roswell-area holdings and water rights in 1900. Hagerman, through his Felix Irrigation Company, had already agreed to sell his claims to the Hondo's floodwaters to the Reclamation Service. [19]

Meanwhile, the irrigation company filed a formal protest against the Reclamation Service proposal, and Newell authorized formation of a board of engineers to examine the company's claims. (The Reclamation Service regularly utilized the concept of an independent "Board of Engineers" or "Board of Review" to adjudicate potentially controversial issues.) The board conducted a series of hearings in Roswell during September 1904, and prepared a final report immediately thereafter. The board's report maintained that the irrigation company's water shortages were caused solely by the company's poorly-built, leaky physical plant, and that the company could more than double its acreage if reservoir and canal leakage were reduced. The company's claim of a water right on the Hondo was also refuted. The board concluded by recommending "that the protest be overruled and the Hondo Reservoir Project be constructed as early as practicable." [20]

The Hondo Reservoir dispute was quickly destined to become a moot issue, however. Following two years of unusual drought, in October 1904 the Pecos River's eccentricities were manifested in the largest, most devastating flood the valley had seen in years. The flood caused significant damage throughout the Pecos basin, although the heaviest losses were felt in the Carlsbad area. These losses included railroad and highway bridges, the community light plant and cotton gin, and numerous other improvements. [21]

The amount of damage to the Pecos Irrigation Company's physical plant was enormous. Perhaps the best written description of the flood's effects was provided by W.M. Reed, a Reclamation Service engineer who visited Carlsbad several days after the height of the flood. Reed reported damage to the irrigation company's entire network, including both dams, much of the canal system, and the new concrete flume. Examining the dams, Reed noted:

The dam proper at McMillan is standing and without any injury, the water having been about 8 feet below the crest. However... about 2000 feet of the [dam's west] embankment, ranging in height from 6 to 12 feet, has been taken away.... The head-gates are still standing but are weakened and with continuous high water and necessarily heavy flow through the gates may go to ruin. The elements will play a great part in the life of these works and may yet do considerable damage before the flood conditions cease.

I found that about 500 feet of the main [Avalon] dam had been carried away and the river, yet in flood, was running through Lake Avalon without interruption. Of 32 gates in the spillway only 8, badly wrecked, were standing. The head-gates are still in, but damaged. The canal below is broken but not as badly as I anticipated. [22]

It was obvious to all that the valley's reclamation system had suffered the worst damage in its history, and that the Pecos Irrigation Company was out of operation for the foreseeable future. The company's fragile financial condition made the prospects for reconstruction flimsy at best. This time, there was no James Hagerman to reassure the farmers and provide a massive injection of money for repairs. The outlook for the Pecos Valley seemed bleaker than it had in years, forcing all parties involved to scramble to find a new solution.

In retrospect, the history of the Pecos Valley's various irrigation companies is both tenuous and disappointing, a story of huge sums of money largely wasted on false expectations and inadequate technologies. During the fifteen years that corporate reclamation was attempted on the lower Pecos, an investment of well over two million dollars failed to produce an adequate, functional irrigation network. Instead, company engineers produced an inefficient, haphazard system, as unable to provide a consistent water supply as it was to withstand the eccentricities of the Pecos River.

Much of the blame for the private reclamation system's failure can be traced to the lack of proven irrigation technologies available to irrigation company engineers. Tracy's analysis of the irrigation company as "real pioneering" was both accurate and perceptive — the Pecos Valley's promoters were undertaking reclamation work at a scale and level of complexity heretofore nearly unknown in the American West. While this undeniably proved discouraging and frustrating to the system's nineteenth-century entrepreneurs, it makes the Pecos projects highly significant as a case study of early, large-scale western reclamation.

|

| In October of 1904 another devastating flood swept down the Pecos Valley destroying Avalon Dam for a second time. A reclamation engineer who examined the wreckage at Avalon reported, "I found that about 500 feet of the main dam had been carried away. . ." — Carlsbad Irrigation District, Carlsbad, New Mexico; December 18, 1905. |

Among the irrigation system's physical features, Avalon and McMillan Dams were easily the largest and most significant. The rockfill design of both structures represented innovative reclamation engineering for the day, as one stage in a complex evolutionary process of dam design. Rockfill dams such as Avalon and McMillan consist of loose, dumped rocks which, by their mass, resist the horizontal force of the water the dam impounds. The dam must rely on an impermeable zone or membrane to keep water from passing through it. Rockfill dams may be divided into two categories, those with a waterproof upstream face and those with an impermeable core. In twentieth-century practice, the upstream face of the former is generally concrete and the core of the latter is impermeable earthfill. Rockfill dams with an impermeable upstream face are the older of the two types; the widespread acceptance of this structural form dates to the years following the California gold rush when miners needed to impound water for hydraulic mining. The earliest dams in the mining regions were small, timber-crib structures with a plank upstream face, based on a technology widely used in the eastern states. As miners built larger dams, the timber cribs became rock-filled, and eventually the timber cribs were eliminated altogether. These dams were rendered relatively impervious by anchoring an upstream face of wood planks to the rockfill. Such dams were favored because they were less expensive to construct than masonry dams and they were considered less prone to failure than earthfill dams. It was not until the late nineteenth century that the upstream wood planking began to be superseded by concrete. [23]

Late in the nineteenth century, the use of an impermeable earth core or upstream apron became more common. Some dams had a central earthfill core with rockfill both upstream and downstream, while others simply had an upstream zone of impermeable earthfill with a gradual slope and an upstream face of rock riprap to resist the erosive action of the reservoir. As these dam forms developed, engineers finally accepted the safety of rockfill dams, or loose-rock dams as they were sometimes called. Some engineers actually considered rockfill to be the safest dam technology because of the inherent flexibility of the structure. The most highly recommended version of the rockfill dam — used at both Avalon and McMillan — employed the impermeable earthfill upstream zone and a riprapped upstream face. Such a structure was sometimes called a "composite dam." Some engineers preferred not to consider composite dams a sub-category of rockfill dams, because the earthfill zone made them more comparable to standard earthfill dams. Others argued that composite dams were truly rockfill dams because the mass of rock provided the main resistance to the horizontal force of water in the reservoir, while the choice of impermeable element — wood, earth, concrete, or steel — was of secondary importance. [24]

Contemporary professional observers considered both Avalon and McMillan Dams to "most boldly exemplify" the rockfill dam technology as practiced during the late nineteenth century. Such dams, however, had to be constructed properly. During Avalon's initial construction in 1890, the earth zone was simply backfilled against the rockfill: it was neither wetted nor compacted. Consequently, the potential existed for a sudden, powerful flood to impregnate the loose, sandy-loam earthfill with water, causing the earthfill to settle and exposing the dam's loose rock to the force of the water. This could, in turn, lead to the dam's failure. Unfortunately for the Pecos Valley's residents, the unpredictable Pecos River demonstrated just such a scenario in both 1893 and 1904. [25]

Other aspects of the system's construction also reflected incorrect design based on uninformed judgements or inadequate technology, including the roughly-built canal network and the vulnerable, ephemeral wooden Pecos River flume. These facilities, in common with the dams themselves, reflected the philosophies of current reclamation design, but contained inadequacies that required correction before the system could fill even a portion of its intended potential.

Finally, the grandiose plans of Eddy, Hagerman, and the others were also unfulfilled due to a basic misunderstanding of the land itself. Large-scale irrigation was introduced to the Pecos Valley without a clear understanding of what the land was capable of growing, how local crops could best be managed, and the amount of return these crops could generate. Unrealistic expectations of the valley's agricultural productivity not only left many farmers disappointed, but diminished the revenue of the irrigation companies. As with the reclamation system's engineering, the farmers' eventual success was dependent on refining local agricultural methods and technologies.

The myriad of difficulties encountered by the sponsors of Pecos irrigation projects frequently mirrored the obstacles encountered by other irrigation companies across the West. Late nineteenth-century enthusiasm for corporate reclamation schemes resulted in a variety of private irrigation projects scattered across the western states. Few, however, proved successful; most clearly reflected the inadequate funding, ineffective engineering, and false expectations that characterized the Pecos Irrigation Company and its predecessors. [26]

As a whole, then, corporate irrigation in the Pecos Valley and elsewhere generally proved unsuccessful. The experiences of nineteenth century irrigation entrepreneurs, however, served as a proving ground for the embryonic field of reclamation engineering. As the twentieth century began, this field was poised to initiate a rapid period of expansion and development, and the technologies employed by the early irrigation companies would continue to evolve. Now, however, the impetus for technological advancement was to come from the Federal government rather than the private developer. Nonetheless, the Pecos Valley was once again destined to be a showplace for these changes.

Endnotes

1. Tracy, "Eddy County, New Mexico."

7. History of Chicago: Its Men and Institutions (Chicago: InterOcean, 1900), 83-84.

8. For background material on the evolution of reinforced concrete bridge design, see B.A. Etcheverry, Irrigation Practice and Engineering: Vol. II, Conveyance of Water (New York: McGraw-Hill Book Company, Inc., 1915), 198, 223-224; Carl W. Condit, American Building Art: The Nineteenth Century (New York: Oxford University Press, 1960), 248-254; Condit, American Building: Materials and Techniques from the Beginning of the Colonial Settlement to the Present (Chicago: University of Chicago Press, 1968), 172-176.

9. "Minutes of the First Annual Meeting of Stockholders of Pecos Irrigation Company," February 10, 1902, RG 115, Entry 3, Box 449, File 651, National Archives, Washington, D.C.

11. "Minutes of Second Annual Meeting of the Stockholders of the Pecos Irrigation Company," February 10, 1903, RG 115, Entry 3, Box 449, File 875, National Archives, Washington, D.C.

12. Hagerman, "In the Matter of the Hondo Reservoir." Hagerman stated that, with work, the lower canal's capacity could be increased to a maximum of 600 second-feet.

13. "History of Carlsbad Project — 1912."

14. C.H. Finch to F. H. Newell, February 24, 1903, RG 115, Entry 3, Box 443, File 651, National Archives, Washington, D.C.

15. C.J. Blanchard, "Millions for Moisture: An Account of the Work of the U.S. Reclamation Service," National Geographic Magazine 18 (April 1907): 223.

16. Tracy, "Eddy County, New Mexico."

18. Francis G. Tracy to the Secretary of the Interior, June 23, 1904, RG 115, Entry 4, Box 1, File 25, National Archives, Washington, D.C.

19. James J. Hagerman to W. M. Reed, July 1, 1904, ibid.

20. A.P. Davis, et. al. to F.H. Newell, September 10, 1904, ibid.

21. W. M. Reed to the Chief Engineer, U.S. Reclamation Service, October 10, 1904, RG 115, Entry 3, Box 443, File 651, National Archives, Washington, D.C.

23. J. Barry Cooke and Arthur G. Strassburger, "Rockfill Dams," in Kollgaard and Chadwick, Development of Dam Engineering in the United States, 887; Follett, "Earthen vs. Masonry Dams," 20-21, 28-29; J.D. Galloway, "The Design of Rock-Fill Dams," Transactions of the American Society of Civil Engineers 104 (1939): 3-5.

24. Follett, "Earthen vs. Masonry Dams," 28-29; Galloway, "The Design of Rock-Fill Dams;" responses to Galloway's paper by Howard F. Peckworth, 30-31, by C.S. Jarvis, 68-69, and by Galloway, 83; Creager et. al., Engineering for Dams, Vol. 3, 806.

25. For contemporary analyses of rockfill dam design, see James D. Schuyler, "Reservoirs for Irrigation," Eighteenth Annual Report of the United States Geological Survey, 1896-97: Part IV — Hydrography (Washington: 1897), 645; Follett, "Earthen vs. Masonry Dams," 28-29; Schuyler, Reservoirs for Irrigation, 51-52.

26. Most of these projects are briefly described in Part 3 of Smythe, The Conquest of Arid America.

| <<< Previous | <<< Contents>>> | Next >>> |

rmr/0/chap4.htm

Last Updated: 01-Feb-2008