|

Fort Vancouver

Historic Structures Report |

|

| Volume II |

PLATES

| |

|

Plate VII. An Additional Step in the Operation of

a Present-Day Screw Press. After the press is full of furs, the manager places a second piece of burlap on top of them and begins to turn the screw to compress the bale. From The Beaver Outfit 279 (December, 1948): 29. | |

| |

|

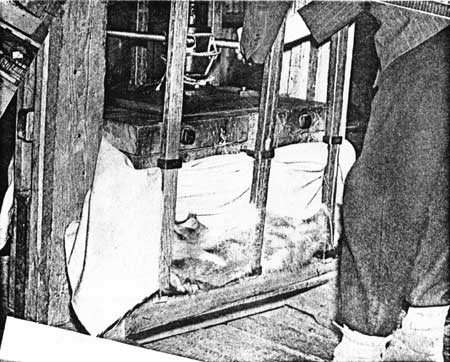

Plate VIII. A Partially Compressed Bale of Furs in

a Screw Press, ca. 1943. This press is not the same one shown in the two previous plates, but it is of similar construction. It will be noted that pack cords are not employed with modern presses. From The Beaver Outfit 274 (December, 1943): [27]. | |

| |

|

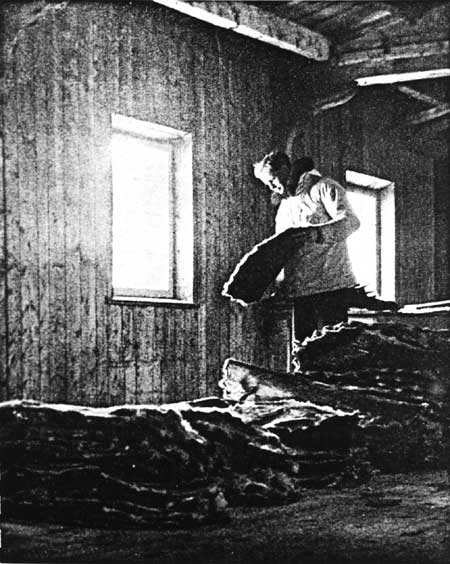

Plate IX. A Compressed Bale of Furs Being Sewn Up

in the Press, ca. 1943. The next stage in the process of packaging the furs is to mark the bale for shipment. This operation is illustrated by Plate CX in volume I. From The Beaver Outfit 274 (December, 1943): [26] | |

| |

|

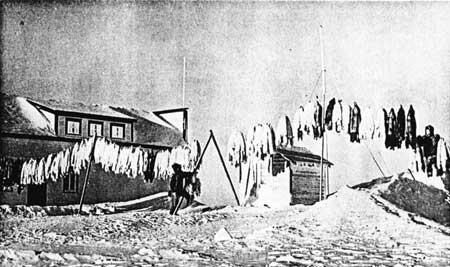

Plate X. Fox Skins Hanging Out to Dry at a

Hudson's Bay Company Post, ca. 1950. Pelts were periodically hung out for cleaning and airing at Fort Vancouver in much this same manner. From The Beaver Outfit 281 (December, 1950): [39]. | |

| |

|

Plate XI. Sorting Furs at Fort Chipewyan,

Alberta. The furs visible are largely muskrats and foxes. From The Beaver Outfit 275 (June, 1944): [9]. | |

| |

|

Plate XII. Sorting Furs in the Warehouse at York

Factory, ca. 1938. From The Beaver Outfit 269, no. 3 (December, 1938): 461. | |

| <<< Previous | <<< Contents >>> | Next >>> |

http://www.nps.gov/fova/hsr/hsr2-p1.htm

Last Updated: 10-Apr-2003