|

Explore the job descriptions below to learn about key positions at Hopewell Furnace.

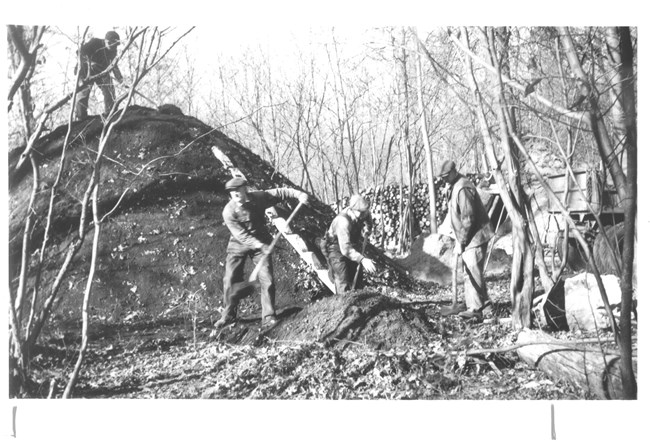

NPS Photo Woodcutter:A large portion of Hopewell’s work force was made up of woodcutters. From 1835 to 1837, 112 out of 213 employees on the payroll cut wood for charcoal making. Collier:Colliers produced charcoal by charring it in pits under carefully controlled conditions. During coaling, the master collier and his helpers lived in primitive huts near the pits. Charcoal making is still demonstrated at Hopewell Furnace annually.

NPS Image MinerEarly miners worked in surface pits, usually in two-man teams. Some were employed by a furnace and others developed mining partnerships and sold ore at contracted prices.

Photo by Brian Kurtner Teamster:Furnaces employed their own teamsters or contracted with men who owned teams and wagons. A trip to Philadelphia, for which the furnace paid the teamster’s expenses required several days. Founder:The success of an ironmaking operation depended on the experience, skill, and judgement of the founder, whose job it was to keep the furnace running at peak efficiency. A founder maintained the proper smelting temperature and determined when the iron was ready to tap. A poor product brought a lower wage and reduced the furnace company’s revenue. A poor founder was quickly dismissed.

Photo by Brian Kutner Keeper:The keeper served the founder and ensured the proper functioning of the blast equipment. Filler:Keeping the furnace charged was one of the hardest and hottest tasks in ironmaking. At the direction of the founder, the fillers damped barrows and carts of charcoal, ore, and limestone into the “tunnel head.” Before scales were used, the founder depended on the fillers to approximate the amount of each ingredient. Fillers endured the flame, smoke, and cinders at the tunnel head and work in all-weather but were paid little more than common laborers.

NPS Photo Gutterman:Before the iron was tapped, the gutterman prepared the sand bed on the cast house floor by raking it and digging channels into which the iron flowed. They stacked the hardened bars outside the cast house for transport. Gutterman, often boys, also hauled away the cooling “cinder” to the slag heap. Moulder:The casting of iron products was an exacting craft, and the moulders who practiced it were among the highest paid of ironworkers. It took years to gain the necessary skills, and the craft was often passed from father to son. Moulding techniques are still demonstrated at Hopewell Furnace annually.

NPS Photo Blacksmith:Blacksmiths were valued citizens known for the utility, quality, and beauty of their work. Equipped with a hand-powered bellows, hearth, anvil, hammers, tongs, punches, chisels, and forms, a blacksmith turned out horseshoes, nails, weapons, wagon tires, cooking utensils, and agricultural implements. He was also a general repairman who restored and re-edged tools and machinery and shod horses, mules and oxen. Today, volunteer blacksmiths periodically demonstrate their craft at Hopewell Furnace.

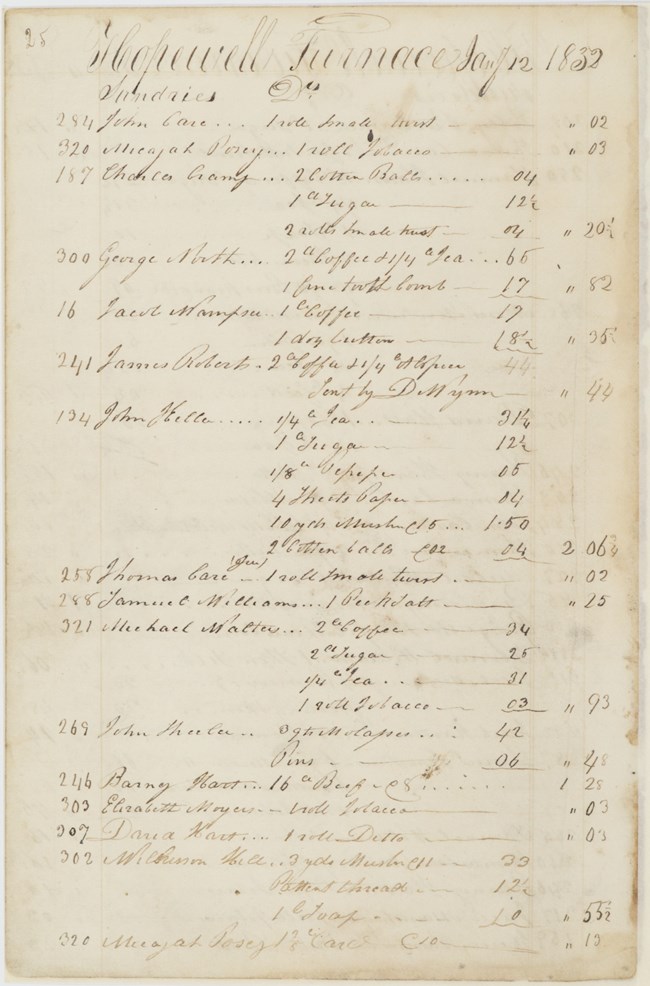

NPS Photo Clerk:Clerks kept books and acted as paymaster. He also managed the company store, ordering supplies for the village and charging workers’ purchases against their wages. He was trusted with setting proprieties for filling orders and could extend credit. He also managed the furnace in the ironmaster’s absence. The holders of this prestigious job often lived in the home of the ironmaster, a position that an enterprising clerk had a good chance of attaining.

Photo by Brian Kutner Ironmaster:A good ironmaster was a capitalist, technician, market analyst, personnel director, bill collector, purchasing agent, and transportation expert. Many learned the business by working their way up the ladder at an ironworks. Others, such as Mark Bird, inherited the business and their position from their father. |

Last updated: June 17, 2025