By Henry Karpinski

By 1928 it was obvious that a new bridge over the great river was needed.

It was equally obvious that this would be no ordinary job.

SWAY WAS A CONCERN.

The 1921 bridge danced in the winds that regularly came roaring through the inner gorge and on at least one occasion it was reported to have capsized. The new crossing must be built to maintain rigidity in all conditions so as not to frighten (or kill) the many tourists that were expected to ride or walk upon it.

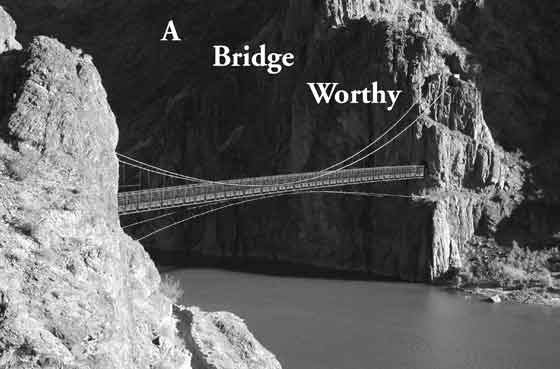

The structure was to be longer than any bridge within the Forest or Park Service-

five hundred feet between the supports- which, in turn, were to be anchored deep into the maddeningly hard "Rose Granite". Requirements were that the span would be able to support a pack train of any length as well as provide for congestion or stampede.

Since 1922, when Phantom Ranch opened, ever-increasing numbers of visitors were clamoring to ride the mules down and it did not take long before the inadequacy of the first bridge became apparent; only one rider at a time was allowed to cross and the delay--while not the imposition that the old cable and cage presented-was nonetheless prolonged and irksome. On January 4th, 1928, F. A. Kittredge, Chief Engineer for the National Park Service, wrote Grand Canyon Superintendent, Miner Tillotson;

"Your letter of December 3rd regarding proposed Kaibab Trail suspension bridge is at hand and we have given it a great deal of study.…we have within the last few days received allotment advice No. 253, which includes $48,000 for immediate construction of this structure."

A camp accommodating nine skilled laborers and an (all-important) cook was established at the confluence of the Colorado and the Bright Angel Creek-later the crew was increased to twenty. Construction commenced on March 9th, 1928. The site selected for the new structure was about sixteen feet directly over the 1921 bridge, the use of which was uninterrupted throughout the duration of the project..

Work began with the building of the north anchorage. Into the granite were sunk a pair of pits-fourteen feet for the upstream anchorage and four feet for the downstream one. So as not to disturb the moorings of the old bridge, extreme caution, even delicacy, was exercised in the use of explosives and machinery. After forms were built and concrete poured and set, steel was put in place and much of the displaced rock was used as fill over these forms. John H. Lawrence, Construction Engineer for the project, estimated that, "… the north cable anchorage is good for a resistance to horizontal tension of over four hundred tons, and a vertical uplift (of) one hundred and fifty tons".