Last updated: August 15, 2025

Article

Weave Room Frequently Asked Questions

The short answer? It depends! How fast the loom is going is determined, in part, by the machine. Modern industrial looms run considerably faster than the early 1900s belt-driven looms on display in the weave room. How quickly a loom makes fabric, and how much, is specific to what kind of cloth the loom is weaving. Two main factors go into how much fabric a loom produces: loom speed and pick count.

Loom speed is measured in picks per minute (ppm). One pick is one pass of the shuttle across the width of the loom, laying down one weft thread. The looms that you see in the weave room are running at approximately 140-150 ppm, so the shuttle goes across the loom more than twice a second!

Pick count is measured in picks per inch (ppi) – in other words, how many weft threads there are in one inch of the fabric. This is set by the gears of the loom that move the fabric forward with each pass of the shuttle.

As a result, the rate that fabric is produced will not be the same on every loom. A fabric with a high thread count will take longer to weaver than a coarser fabric with a low thread count. Take, for example, two looms running at 140 ppm. If one is weaving 70 picks per inch, and the other is weaving 140 picks per inch, in the same amount of time the loom with fewer picks per inch will make twice as much fabric.

In the weave room, we use electric motors (mounted on the ceiling) to drive the line shafts, which in turn run the leather belts that power our looms.

The first mills used water wheels to drive their line shafts. Next, water turbines drove the line shafts as technology improved. After that, turbines and steam engines powered electric motors to drive line shafts. Eventually, in the mid-1900s, line shafts and belts were replaced by a separate motor for each loom. These motors would be powered by either the wider electric grid or mill-supplied power.

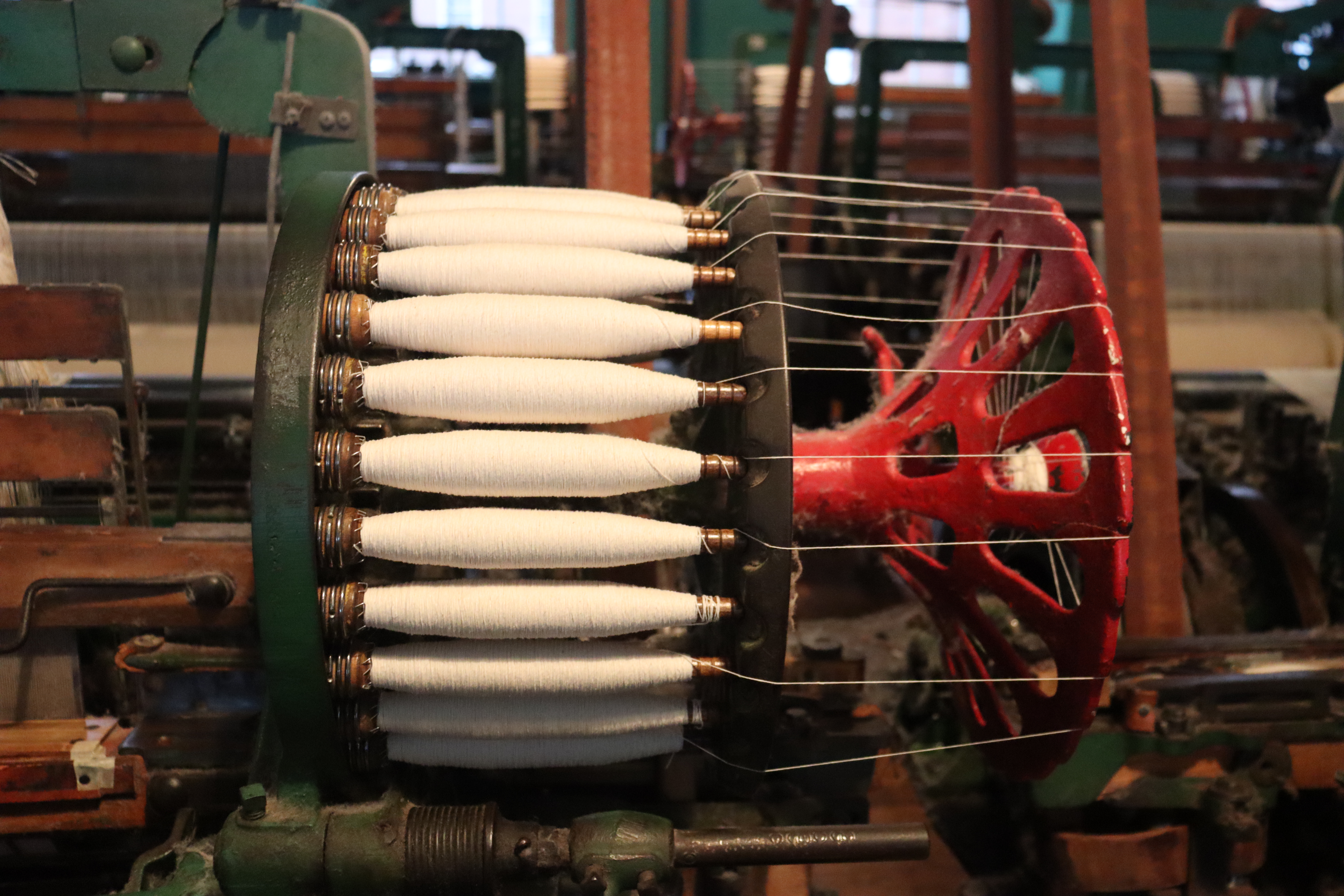

That’s a device called the bobbin battery. Early looms were designed to stop when the bobbin in the shuttle ran out of thread. This meant that the weaver had to manually replace the empty bobbin with a full one and re-thread the shuttle so that the yarn would feed out correctly. This limited how many looms one weaver could run, since each loom needed more attention.

In the 1890s, James Northrop, an employee of the Draper Corporation – the same company that made our looms on display in the weave room – patented the bobbin battery. The battery is a rotating drum, filled with new bobbins, that automatically replaces the bobbin in the shuttle with a full one as it runs out. The empty bobbin drops into the box below the battery to be collected and refilled by a worker. This allows the loom to run without stopping and one weaver to be responsible for many more looms.

This would be different across different time periods and be different from mill to mill. Management calculated a weaver’s workload according to the type of loom, the style of fabric, and their experience and skill.

In a weave room like ours, which has about 90 looms, in 1915, there may have been three weavers running the looms, plus an additional spare weaver who would double as a smash piecer (responsible for repairing any major problems with the looms, such as a large number of broken ends).

This also varies from mill to mill, depending on the time period. Early weavers worked an average of 70 or more hours per week and stopped their looms to return to the boarding house to eat lunch. In the later 1800s, production would not stop for the workers to eat.

With the invention of reliable electricity, mills – no longer directly dependent on water power – would run around the clock. In slower times of year, a weaver’s hours might be reduced.

In 1916, roughly the era that our weave room is from, most workers at the Boott Mill earned between $8 - $11.99 a week.

This equipment is over a hundred years old and comes with its own set of challenges. One is obtaining the materials needed to make cloth, especially the warp beams. Warping requires its own specialized set of equipment that takes up a lot of space! While mills at the time would have had all the needed equipment in the same building, we have a harder time finding places that can wind warps for us.

Another is maintaining and operating the demonstrations safely. This equipment was made before the days of the Occupational Safety and Health Administration, safety guards, or modern industrial standards, so it requires caution to use and work around while keeping everyone safe.