Last updated: July 7, 2021

Article

Timber-Framed Steeples - Engineering a Steeple Restoration

HISTORIC AMERICAN TIMBER-FRAMED STEEPLES

V. Engineering a Steeple Restoration

This article is fifth in a series to discuss the form, function and joinery of selected historic American timber-framed steeples. The series was developed from original research under a grant from the National Park Service and the National Center for Preservation Technology and Training. Its contents are solely the responsibility of the authors and do not represent the official position of the NPS or the NCPTT.

THE stability of a steeple in the wind depends on its anchorage to the building’s foundations. Steeples may stand free on their own foundations or they may integrate into the endwall or sidewall framing of a larger structure, usually a church. Many roof-mounted timber-framed steeples divide their bearing, with two posts on the endwall of the church and two posts on the first interior roof truss. In many cases, the two interior posts pass through a balcony structure. Endwalls may be timber framed or masonry.

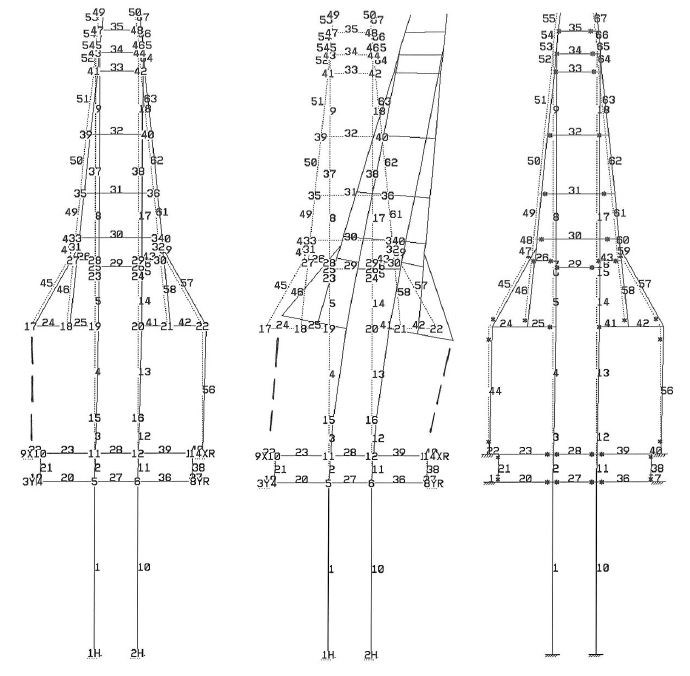

Some steeples comprise square, hexagonal or octagonal stages erected in telescoping fashion and surmounted by a spire, including between their stages transitional structures called crabs. For these steeples a three-dimensional engineering analysis may be most appropriate. A two-dimensional or plane frame analysis may be appropriate for other sorts of steeples.

The engineering analysis of a steeple should consider wind pressure in four directions. No matter what the configuration, wind and seismic forces should be applied in the transverse directions (across the ridge of the main structure) and in the longitudinal directions (parallel to the ridge). Many roof-mounted church steeples lean back toward the nave when support is shared between an endwall and a lessstiff roof truss. Even with the rigid support of timber posts and balcony or narthex wall framing, a steeple will eventually lean if the endwall support is a nonyielding masonry wall. In these cases, a small amount of shrinkage across the grain in each of several large timber plates on the nave side can collectively cause a dramatic lean in a tall church steeple.

For ease of analysis, the timber frame of a steeple may be reduced to primary and secondary framing comprising posts, beams and bracing. Rigidity may depend on X-braces, short knee braces or longer up- or down-braces connecting post to sill or plate, usually at a steeper angle than 45 degrees and running across or through several studs.

A preliminary analysis will reveal whether braces are resisting tension or compression forces. If the computed tension is high, and the ability of the connection to resist tension insufficient, all such tension members should be deleted from the analysis and the program re-run.

The computer model must account for continuity or discontinuity through joints. In the past, traditional truss analysis required that all joints be hinged (able to rotate) to compute axial forces by graphical analysis or the methods of shears or moments. In these cases, bending forces in continuous members were ignored. With the computer and appropriate software, we can provide joints with hinges or we can run members continuously through an intersection. To model half-lapped or intersecting members, a link can be added to the model that allows full or partial continuity through the joint as well as rotation. We can also model springs that allow a support a given amount of movement in response to a given amount of force. Computers thus enable us to more accurately determine the theoretical stiffness of timber trusses and frames.

For steeples with securely fastened sheathing or panels, the additional stiffness thereby afforded to the frame should also be accounted for in the computer model. Despite the relative light-ness of their materials, these elements can make a difference.

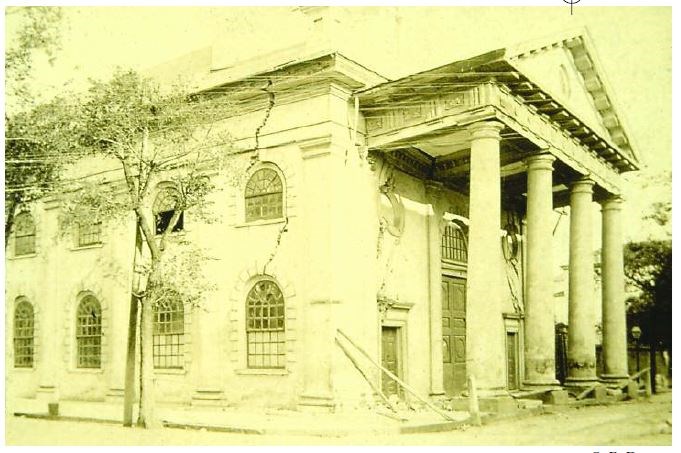

Hurricane Hugo struck near Charleston at the Isle of Palms in September 1989 and caused damage to St. Michael’s resulting in an insurance settlement of $6 million. The winds of this Category 4 storm were sufficient to bend the tapered 2½-in.-square wrought-iron bar carrying the weather vane at the top of the steeple.

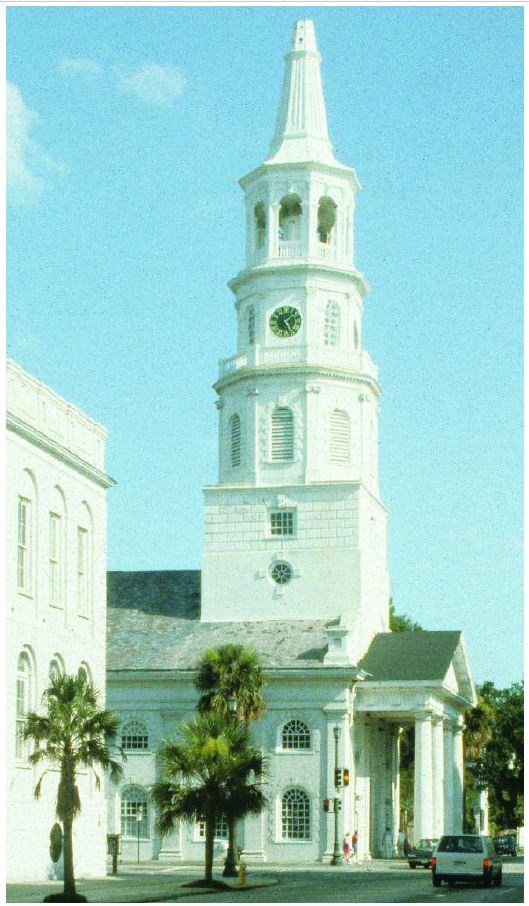

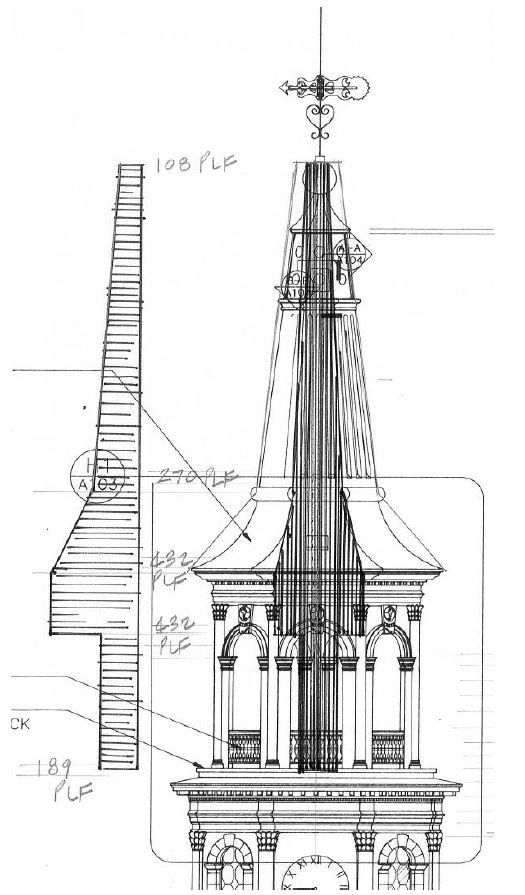

The steeple comprises five stages above the roof. The first stage, a square tower pierced by small circular and square windows and partly rusticated in its exterior finish, extends down through the body of the church to form the center portion of the vestibule. Its brick walls vary in thickness from 4 ft. 9½ in. to 5 ft. 3 in. The masonry box, translating from square to octagon, rises through two more stages, the bell stage and the clock stage, to the underside of the open lantern stage. This fourth stage is timber framed, as is the spire, the fifth stage that completes the steeple (Figs. 2–3 ).

The wood roof trusses in St. Michael’s, splendid compound kingpost and queenpost trusses spanning approximately 50 ft., are entirely independent of the steeple.

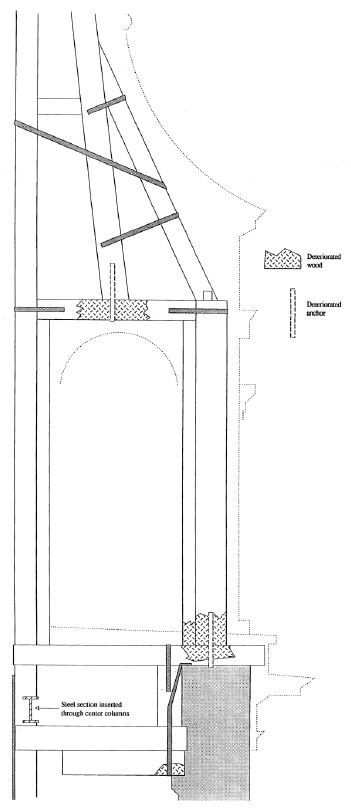

After Hurricane Hugo, materials conservator George Fore, of Raleigh, North Carolina, produced a condition analysis and conservation study of St. Michael’s carpentry, masonry, plaster and finishes. He also provided framing details for the steeple as well as evidence of racking of the upper structure attributable to Hugo, and his report graphically located areas of deteriorated wood within the framework (Figs. 11–12).

To determine the amount of static lean in the steeple, a surveyor set up an instrument in the window of a nearby office building, but measurements were inconclusive. I then made a direct inspection on a day with 5- to 10-mph wind gusts. Craig Bennett P.E. of Cummings and McCrady, architects in Charleston, led me on a climbing tour to the open lantern.

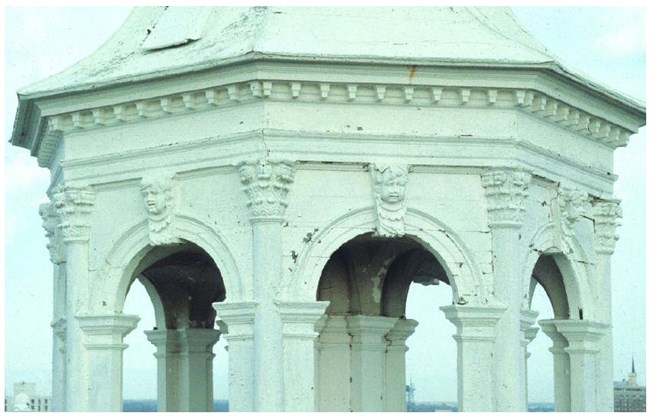

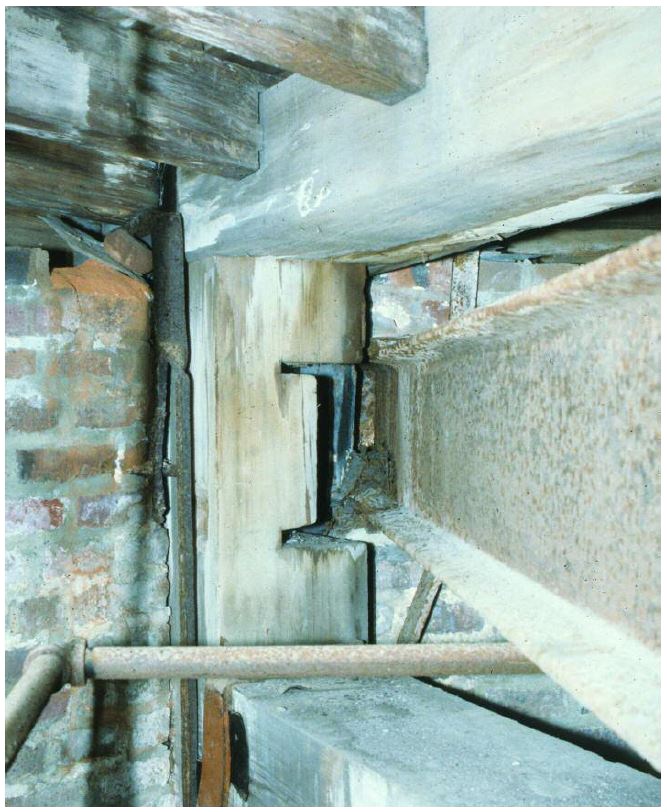

On the day of our visit, we could feel the sway of the lantern and hear the timbers rub against one another. I was impressed by the scale of the structure and the early iron straps and pins added to stiffen the section above the open lantern, a wonderful place with decorative panels, arched openings, curved ceilings and a weatherproof floor covered by lead sheets with tight flat seams.

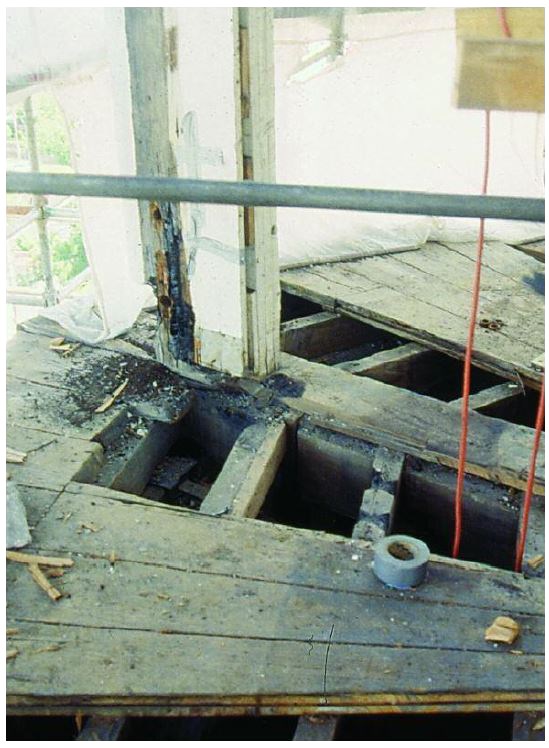

(Exposed, the floor later proved to be caulked with oakum and tar. After repairs to the framing beneath, it was eventually re-covered with sheet copper. See Figs. 15–16.) Access to the lantern was provided by a spiral stair beginning in the clock stage and encircling the primary 8x8 pendant timbers in the central core of the lantern, inside an enclosure cased to match the exterior treatment of the lantern (Fig. 4 ).

Of prime concern to all of us were the horizontal steel beams introduced into the steeple in 1938, apparently to provide additional vertical support to the steeple frame (Figs. 9–11). The eight original 8x8 pendant core posts descending from the spire to the masonry clock stage were severed two-thirds through to accommodate these struts. In September 1990 we produced a preliminary structural evaluation report including these observations:

The introduction of horizontal steel members in the steeple may have caused a discontinuity which is the second major concern. This steel, while providing vertical support, has nearly severed vertical elements which provide a great deal of the overall stability to the steeple. . . . At first glance it would appear that the open condition of the lantern level of the tower is the source of the steeple’s inability to resist lateral forces such as wind. But the original designer did provide an excellent method of lateral stabilization with a vertical cantilever which acts much like a flagpole embedded in the ground. The bundle of eight vertical timbers telescopes from the brick masonry box below. The continuity of the eight timbers which extend from the massive masonry ring below the clock level to well into the spire was disrupted by the steel sections which were inserted in 1938. . . . At this time, we agree with George Fore that the deteriorated steel should be removed from the tower, the masonry pockets filled, and the damaged vertical members repaired. Repairs should include epoxy consolidation, epoxy-aided splicing, replacement-in-kind, and appropriate reinforcing which will not change the intended action of the existing structural system or sacrifice original historic fabric.

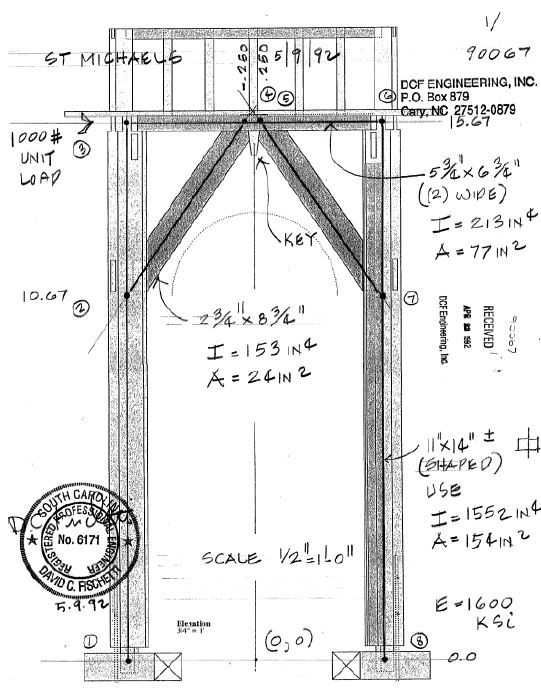

We issued a final report in May 1992, offering a simple analysis of the steeple and allowing us to consider a replacement-in-kind option without supplemental steel reinforcing. For our engineering analysis, we adopted a Use Factor of 1.00 (from the 1988 Standard Building Code) because we thought it highly unlikely that failure of the spire would affect 300 or more occupants in the sanctuary. The limited use of the church sanctuary, normally one day a week, was another reason for selecting the low factor. We applied a support condition to the spire-lantern frame amounting to the approximate stiffness of the two portal frames. The purpose of this exercise was to obtain the most realistic model of the spire by combining the stiffness of one intersecting frame with two portal frames, each of the latter comprising two lantern posts and two 2¾x8¾ knee braces. In determining the stiffness of the portal frame, we deleted the contribution of knee braces when in tension.

We applied a horizontal 1000-lb. unit load to the portal frame to derive the spring constant. To simulate the spire with the base of the lantern perimeter posts not tied down, we placed a roller sup-port with a spring constant in the Y direction at the bottom of the windward post in the portal frame. Using the stiffness of the “deteriorated” (unrestored) portal frame, we re-ran the steeple frame with a new spring constant and the lantern post omitted on the windward side. We used a Modulus of Elasticity of 1600 ksi and limited Fc (compression parallel to grain) to between 1200 psi and 1700 psi and Ft (tension parallel to grain) to 1100 psi (Fig. 8).

The analysis provided the following computed horizontal deflection of the top of the steeple frame under a 100-mph wind load:

As built 2.13 inches

Deteriorated 5.43 inches

This response seemed to be in line with actual conditions. If the spire and lantern were experiencing much larger movements, then their sheathing, cladding and architectural features would be rupturing badly. Each of the eight faces of the lantern stage is sheathed by decorative millwork comprising an arch with exceptional carved applied keystone, engaged columns with carved capitals and smooth entablature (Fig. 4). The lower elements of the lantern architrave were actually molded into the stacked horizontal planks from which the arch was cut, probably by a special-bodied plane shaped like a cooper’s croze. George Fore’s investigation did point out fractured paint lines at some joints between the planks, indicating that this level of the lantern had indeed racked, causing the horizontal planks to slip past one another. Stresses in the various members appeared to be relatively low in their net sections, consistent with a timber-framed structure where the connections govern the design. The highest stress appeared in the interior core posts at the top of the lantern stage, because a large amount of bending was applied to a small net section. (The eight 8x8s, telescoped through the masonry box, resist wind loads in bending through cantilever action. Rotation in the vertical plane of the spire causes maximum bending in the upper portion of the 8x8s.)

As investigation proceeded, the original marriage marks on the scribed timber frame revealed themselves to correspond to compass points. The points shown on our plans keyed to the marriage marks as follows: SSW–I, WSW–II, WNW–III, NNW–IIII, NNE–V, ENE–VI, ESE–VII, SSE–VIII.

Our analysis appeared to set the stage for a replacement-in-kind solution where severely deteriorated members are wholly replaced and the deteriorated ends of other members are repaired.

Tommy Graham, of McClellanville, South Carolina, had been selected by Hill Construction Corporation of Charleston to pro-vide the timberwork in the restoration of St. Michael’s steeple. Though my first inclination was to replace in kind the deteriorated timbers and portions of timbers using mechanical splices, Tommy suggested that we make repairs using Dutchmen and a gap-filling epoxy adhesive to maximize the retention of historic fabric. Besides, he said, it would be problematic to acquire large dense cypress timbers dried to a moisture content compatible with the timber inside the tower. To test the epoxy, I directed Tommy to have his crew prepare, under field conditions, six 1-in. by 3-in.-long half-lapped specimen joints that could be transported to a testing laboratory (Fig. 13). With the assistance of the Raleigh office of Froehling & Robertson, Inc., an independent testing laboratory, we tested the specimens at North Carolina State University’s Forestry Department using a Tinius-Olsen testing machine. The results tabulated in F&R’s report of tensile tests were fairly uniform:

| NO. | M.C.% | Breaking Load(lbs.) | Stress (psi) |

|---|---|---|---|

| 1 | 10.4 | 2510 | 846 |

| 2 | 10.3 | 2500 | 842 |

| 3 | 10.2 | 2855 | 973 |

| 4 | 10.6 | 3040 | 1035 |

| 5 | 10.4 | 2390 | 812 |

| 6 | 10.5 | 1845 | 634 |

| Avg 857 |

We applied a factor of safety of four to the average value obtained by the testing program and used the result to design moment splices between the original wood and rebuilt ends of several of the spider beams. In one case, we discovered a horizontal strut that was totally deteriorated. To replace it, we laminated five cypress boards together on edge (Fig. 14).

New bottom tenons or tenoned ends as necessary for those perimeter posts that had deteriorated at the lantern floor were fabricated from dense cypress with a moisture content of 14 to 16 per-cent, close to the 11 to 14 percent moisture content of the original frame (Figs. 15–16).

Where the radial 8x10 horizontal timbers (or spider beams as we called them) below the floor of the lantern were severely deteriorated, we replaced them with pressure-treated Southern yellow pine having a 2.5 pcf retention of copper chromated arsenate (CCA) water-borne preservative. These members, embedded 3 ft. deep inside the heavy masonry walls near the top of the clock stage and cantilevered toward the center across brick corbels, provided stabilization and some vertical support to the central spine of the spire. Wrought-iron straps throughout the steeple that had disintegrated too far to be reworked were replaced with stainless steel.

The rehabilitation of St. Michael’s steeple required the combined efforts of an architect, an engineer, a materials conservator, a timber framer, a general contractor and a representative of the church. Louis Dawson III, representing the building committee of the church, participated in day-to-day decisions. Besides our reliance on George Fore’s materials report and Tommy Graham’s timber framing expertise, we enjoyed the frequent advice of consultant John Laurens of Charleston, a near neighbor of the church and an expert in historic fabric. The steady support of Craig Bennett and Dan Beaman A.I.A., also of Cummings & McCrady, Inc., was essential to our own contribution to this project.

––David C. Fischetti

David C. Fischetti P. E. (office@dcfengineering.com) operates DCF Engineering, Inc., in Cary, North Carolina, and has long experience with the repair of historic structures.