Last updated: April 7, 2025

Article

The Space Age in Construction

Conservation Science Institute (CSI)

Conservation Science Institute

Researchers: Justine P. Bello, Caroline Guay, Tom McDowell, Mark Rabinowitz, Joseph Sembrat

Caroline Guay: Good morning. I’ll be speaking about space age and architecture, what influenced space-age design, how it impacted our lives, the development of space age materials that came out of the space program, and, ultimately, how we are now tasked with having to conserve those materials. The influence of the machine age on architecture and design is well documented, as seen in the streamlining of art-deco and modernist styles. By contrast, the space age is typically understood as more of a cliché or stylistic fad than an academic architectural influence. While there is a visual progression from the streamlined locomotives of the 1930’s to the scenic cruiser coach of the 50’s through to the Avanti automobile of the 1960’s, that design influence did not continue into Skylab of the 1970’s, although all were designed by Raymond Loewy. An interesting anecdote is that NASA did approach Loewy and gave him a stage three of a Saturn 5 rocket and basically said, “Make it fit.” He did advise on the arrangement, size, and even color scheme of the living quarters for the astronauts aboard the space station.

Aircraft design in the late 20’s and into the 30’s became more aerodynamic and made use of advancing technologies to increase speed and reduce drag. Industrial designers were heavily influenced by the new, streamlined aircraft design, cylindrical forms, and long, horizontal windows, horizontal lines and curves all conveying motion and speed were successfully scaled down for use in locomotives and automobiles, even scooters. These design elements appeared in all forms of transportation, no matter how simple. This look was also incorporated into the design and manufacture of consumer goods. Toasters, fans, clocks, radios and vacuum cleaners. The possibilities were endless. Leading innovators, like Buckminster Fuller, gave us futuristic designs like Dymaxion car, Dymaxion house and the Geodesic Dome.

Post World War II America was a period of optimism. The country was experiencing vigorous economic growth, a baby boom, and saw great advances in science and technology. With the construction of highways across America and the growing car culture of southern California, businesses were trying to attract the attention of passing motorists. A new style of roadside architecture developed appearing as drive-ins, diners, bowling alleys, and particularly influenced the design of signage and, in the bottom right hand corner is Googies. The term was coined in 1952 by architectural critic Douglas Haskell when describing architect John Lautner’s Googie’s Coffee Shop in Los Angeles. A new design was emerging featuring aerodynamic elements such as up-swept and cantilevered roof lines, geometric, boomerang, amoebic, starburst, atoms and parabolic shapes came to characterize this style. In addition to the use of large expanses of glass, bright colors, neon lights and plastic paneling, Googie reflected the optimism of the time and how society was embracing technology and science and moving towards the future, but at the same time, remaining accessible to the middle class. While not considered seriously as an architectural movement, Googie design represented a lighthearted and whimsical aesthetic that helped to launch the space age style that ultimately grew out of it.

The beginning of the space age could be marked by the Soviet Union launching the satellite Sputnik 1 in 1957 and the subsequent decision by the U.S. government not to be surpassed by the Soviets. The impact on popular culture was immediate and pervasive. In television and film, The Jetsons, 2001: A Space Odyssey, and Barbarella perpetuated the Googie visual style combined with space race themes. The 60’s brought increasing momentum to the space race and, with it, increasingly futuristic design employing new materials and experimenting with new shapes, masses, and volumes. It’s influences could be seen throughout all aspects of American culture, in movies, TV, furniture, fashion, and music. And while Googie began as a fanciful marking concept, the futuristic design of the 60’s became more purposeful, studied, and academic. World fairs have always been a showcase of innovation, technology science, and culture and this was exemplified in the pavilion architecture and the use of modern building materials to create new forms. The Automium in the 1958 World’s Fair in Belgium, the Space Needle at the 1962 Seattle World’s Fair, Tent of Tomorrow and the United States Space Park at the 1964 New York World’s Fair and Buchminster Fuller’s Geodesic Dome at Expo 67 in Montreal. Attractions at Disneyland even embrace space age movement and futurism with Tomorrowland introduced in ’55 and the Monsanto House of the Future built in ’57.

Conservation Science International (CSI)

Kitsch & Higher Forms of Architecture

The space age eventually inspired higher forms of architecture. Far from the kitsch of Googie, but clearly influenced by space themes, a great number of architects were highly successful in creating designs that still stand the test of time. Neimeyer’s designs for the new civic buildings for Brasilia, including the National Congress and the Cathedral of Brasilia. Also, his contemporary art museum in Niteroi overlooking the city of Rio de Janeiro. The same can be said about Saarinen’s works. His work at the campus at MIT, Kresge Audotorium and the chapel with the stunning interior showcasing the Bertoia sculpture cascading above the alter, the North Christian Church and, of course, the Arch.

A few other examples include the two towers on the upper left. Ten towers were built by the architect Gerard Grandval in the Paris suburb called Creteil. These ten towers are called Les Choux or cabbages. Vilgio Revell’s design for 1965 Toronto City Hall features two curved towers with a saucer shaped council chamber and John Lautner’s designs for the Chemosphere, built on what was deemed to be an un-buildable sight, and the Bob Hope residence in Palm Springs built in 1973. Appropriately, the stylist influence of technology and flight is evident in airport design such as the 1961 theme building at LAX and Saarinen’s Washington Dulles Airport, and the former TWA Flight Center JFK.

Important elements of modern material science are the product of the space race and the government’s desire to make these advancements transferable to the development of commercial products and services for the public. As a result of a 1958 congressional mandate, NASA created the Technology Utilization Program. This accomplished several goals. Justification for the continued expenditure of NASA funds, it served as a tool to educate the media and the general public about benefits and dispelling the myth of wasted taxpayer dollars and it reinforced interest in space exploration. Since the mid-70’s, the number of spin off technology exceeds 1800. These developments have been applied to numerous fields; transportation, communications, medicine, natural resources, energy, but also architecture. The understanding and engineering of lightweight materials and metals that have made space exploration possible also allow these materials to be effectively appropriated into building construction materials. Some of these follow. After the Apollo 1 fire, NASA developed fireproof astronaut suits, which led to improved firefighting suits on Earth. Self-righting life rafts against the downdraft of rescue helicopters are being used today. Cordless tools for moonwalks, Black and Decker developed cordless drills and the dust buster. Then there was memory foam, water filters, smoke detectors, and the original Apollo moon boots revolutionized the design of shoes.

My colleagues have the unique experience of assessing, studying, testing, researching and conserving several significant space age artifacts including space shuttle Atlantis, Saturn V rockets, Skylab and an A-12 Spy Plane and a Corona spy satellite. Through this, they have gained knowledge on the preservation of these exotic materials that can influence the larger sphere for the use of these materials in architecture. The first case study is the A-12 Spy Plane, which was produced from ’62 to ’64 and was in operation until 1968. This was developed by Lockheed’s famous Skunk Works. The A-12 was developed for the CIA to spy on the Soviet Union. The plane’s design required titanium in order to resist intense heat created by supersonic flight speeds. Lockheed’s supplier for titanium had only limited reserves, so the CIA conducted a worldwide search and, by using third parties and dummy companies, managed to quietly purchase the base metal from one of the world’s leading exporters, the Soviet Union. The Russians never realized how they actually contributed to the creation of the airplane that was being constructed to spy on their own homeland.

Prior to the development of the A-12, titanium was a little used and virtually unknown material. The metal was initially refined in the early 19th century, but was not in common use due to the scarcity of the sources until the third quarter of the 20th century. Titanium is a low density material, 60% the density of steel, and can be strengthened by alloying it to suit various purposes. It has an extremely low rate of thermal expansion and has excellent strength-to-weight properties. Although the Russians had used the metal for smaller components on aircraft, they had not developed the techniques to use the material effectively. It was not until the A-12 program that engineers were able to figure out how to effectively work the material into sheets which then allowed them to completely sheet the aircraft. This helped paved the way for titanium later being used in bold architectural statements such as those being created by Frank Gehry.

Conservation Science International (CSI)

CIA A-12 Spy Plane

In researching the preservation of the CIA spy plane, CSI conservators encountered the following oddities associated with the preservation of titanium. Although titanium is thought to be an indestructible material, it was found that this metal exhibits extreme sensitivity to contaminants such as chlorine, fluorine, and cadmium. For example, during fabrication, it was discovered that the chlorine based ink of a Pentel marker used to layout the titanium sheets caused them to fail after exposure to heat. Working with the metal was always a challenge. The biggest issue was how to roll the sheets. The Soviets never figured it out. They used blocks of metal that were milled down. Titanium is extremely hard and trying to drill it resulted in breaking bits all the time. Cadmium plated hand tools has an adverse effect on fasteners, which would fail after exposure to heat and spot wells would break. For this particular aircraft, the biggest problem was peeling paint related to poor adhesion between the top coat layer and what remains of the original paint. The wings had been cut off when the plane was shipped to CIA headquarters in Langley in 2007. The siliconized paint was applied after reattachment would fail. The decals were wrong and, all in all, a very poor restoration, but with a new understanding of this material, the aircraft will be appropriately specified for proper treatment.

Our second case study, or the two Saturn V rockets in Houston and in Huntsville. Just as NASA and DARPA encouraged the spin off of innovations and materials, technology transfer from their weaponry and space programs for commercial uses, conservators have used a similar technology transfer from the aerospace corrosion engineering and coding industries to better understand the deterioration processes and the means and methods available to treat many of the iconic technological wonders of the space age. The Saturn V rockets were unknown territory for CSI. While they had worked on aluminum sculpture and smaller types of artifacts, it wasn’t until they went to Houston to bid the rocket that the task of figuring out how to conserve all of these relatively unknown materials became evident. They went through everything one at a time. They created a bibliography of industry wide aircraft restoration articles to understand what was being done and then culling the information. They approached experts in the field, corrosion engineers, urethane foam experts and, yes, there is a urethane foam institute, water jetting industry people. The specifications had originally called for abrasive media blasting, but through research, they would that water jetting was the accepted practice in the aerospace industry.

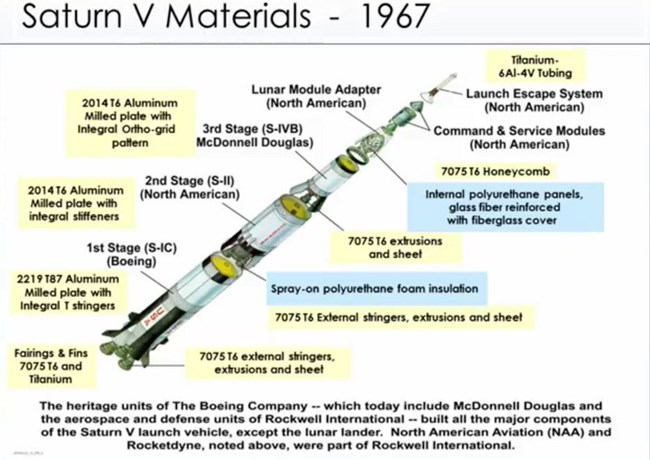

This slide shows the range of either metal or nonmetal materials in the Saturn V. The Saturn V’s are significant for the numerous and exotic array of metals and nonmetal materials that were used in its construction; aluminum, titanium, urethane foam, and even cork. The first stage was even fabricated of asbestos panels. It was important to understand what there was and how the materials were fabricated- extrusions, sheets, and so forth. Saturn V rocket was built primarily of aluminum. Interestingly, stage one of the rocket fired for just 168 seconds, a little over 2 1/2 minutes, before being jettisoned and dumped into the Atlantic. The other two components of the launch vehicle experienced similarly short service lives and none of these stages were ever intended to be recovered. Imagine all this work to conserve something that was meant to last a few minutes. In spite of the disposability, chemical surface treatments to the aluminum and durable protective coatings that were used during manufacture had proven to be quite effective at preserving much of the historic aluminum of the two rockets.

Conservation Science International (CSI)

Saturn V

This is a photo of some of the various metals on the Saturn V, as you can see listed. All the metals were selected for the high strength, low weight characteristics and in the case of engine metals, high heat and sulfur resistance; however, none of the aluminum alloys have corrosion resistance normally associated with aluminum. They are high copper and high zinc content and the key to their short term durability was the application of coropon, the zinc chromate primer, which you will see later. It’s a green finish. The primers provided better protection than the finished coats.

These are examples of material deterioration and it is what you would expect when you have various metals that were only meant to last 2 1/2 minutes. Unlike the space shuttle, these components were disposable. The causes of deterioration included a combination of high humidity, heavy pollution, high UV, high salt aerosol off the coast, and sitting next to a farm, so they were exposed to fertilizers and herbicides. You have galvanic reactions between different metals, collection points where moisture and water collect, and UV breaks down coatings and foams. An earlier attempt to restore finishes was carried out by unknowledgeable people and their intervention likely caused greater deterioration. Early sand blasting spread the salts and then removed the passivating layer from the aluminum. Since the rocket wasn’t meant to last, NASA was not concerned about galvanic reaction, nor do they care about the paint finish; however they were concerned with weight and they still are. The selection of lightweight materials sometimes meant other properties were affected such as corrosion resistance and NASA has since learned their lesson about storing these vehicles. They must be kept in an enclosed facility, not left out to the elements.

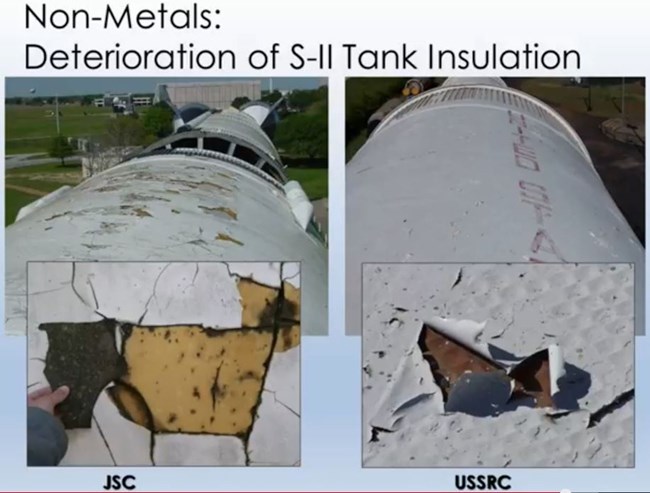

Some of the nonmetal materials used include tedlar, which is a plastic finish, mylar, velcro, a variety of plastics and synthetic rubbers were all developed in the early to mid 20th century, some specifically for NASA, and all were found on the Saturn V. In contrast, a simple material such as natural cork was selected for it’s high level of heat resistance and it was lightweight. It was also so popular they were concerned that they were actually going to deplete the world’s supply of cork. The Huntsville foam insulation system of partial foam-filled honeycomb with a nylon phenolic skin and a tedlar seal, is a version that was not used on any man-flight missions. It was replaced with a spray-on foam insulation that we have on the Houston Saturn V. This is the same foam used on the fuel tanks of the space shuttle and my colleagues, unfamiliar with the differences heading into the Huntsville project, it was just another item that required special research and treatment development time.

Early attempts to provide adequate insulation to prevent freezing of cryogenic fuels used to power the stage two of the Saturn V rocket had included the use of polyurethane foam filled phenolic resin honeycomb which was then encased in a thin film of tedlar. The tedlar facing mirrors a typical installation of sprayed on, closed cell polyurethane foam in a building construction, which is then applied to a flat roof or walls prior to the application of a waterproof membrane. In attempting to preserve both the tedlar skin and the foam substrate of the Saturn V, my colleagues found that after 35 years of outdoor exposure, that the foam actually had become fully saturated with water through infiltration and condensation. Substantial inactive biogrowth was found in these areas where the tedlar was removed. By the way, tedlar is still used today.

Conservation Science International (CSI)

Deterioration of S-II Tank Insulation

A few photos showing the deteriorated finishes on the stage two. The spray urethane foam insulating the Houston tank on the left was extensively cracked, damaged, blistered, trapping water and concealing corrosion of aluminum tank. While what seemed to be a better preserved version in Huntsville with the tedlar appearing to be intact, actually turned out to be far more complicated. Trapped moisture within the honeycomb cell and foam structure and large losses and damage to the tedlar were uncovered after paint removal. The tedlar remained in relatively good condition and most was saved with some repaired areas and, as I said, tedlar is still used today. But, what is interesting, is that closed cell foam isn’t perfectly closed cell. It does have a perm rating and under solar gain, there are pressures that form moistures into the cell and urethane does not bond well to a wet surface. This is just some spec information on tedlar and cross sections of the foam.

Another material is mylar. The rocket’s used different colors and each one had it’s only properties for reflectivity. So, in this particular case, the mylar is acting as a reflecting insulator to keep cryogenic fuels from overheating. Of the Saturn V’s mylar survived in only a few instances, it isn’t UV stable and it deteriorated. Mylar is another one of these products that had a spin off application. As you can see on the right, it is used as a wall covering. This is just a quick slide to show the previous attempt to restore the rocket in ’84. Research into previous treatments show that these were misguided attempts at repairing the problems without first understanding the cause of deterioration and this caused more problems down the road. But we learned from these mistakes and, more importantly, utilizing the most current techniques by borrowing from corrosion and coating industries. The main problems stemmed from overly aggressive coating and corrosion techniques that were not effective in dealing with the main problem being soluble salts. Previous sand blasting spreads salts over the surface then seals them with the new coating system. Catastrophic failure of the coating was visible in a few short years.

CSI tested the appropriateness of ultra high pressure water jetting on aluminum test coupons and original tunnel covers from both Saturn V’s as a method for removing coatings, corrosion, and surface contaminants such as soluble salts. Automotive and aerospace companies have cleaned manufacturing components and removed thermal coatings with UHP water for many years. As you can see in the photograph, the water jetting technique could be tailored to take it down to bare metal or just to remove the top coats, leaving the original coropon primer and fabrication stamps below intact. Just a photo of the technique. Once the proper testing and analysis was complete, the work moved to full scale treatment and it was decided that it was more important to remove soluble salts from corrosion pits, so it was cleaned to bare metal. Unlike NASA, the city of Houston has very strict VOC regulations, which prompted CSI to use a waterborne coating system. In addition, the client wanted a coating system that could be touched up with minimal preparation and touch ups that would visually integrate with the existing finish.

Conservation Science International (CSI)

Saturn V

And the final product. This is the space and rocket center in Huntsville, but both Saturn V rockets were treated the same way. The decals are actually recreated by the company that produces bus wraps. So, we have provided a few examples of space age materials and how we have attempted to solve problems, but there are other materials that have been used in architecture and we will need to learn how to deal with. The following are but a cursory look at other technologies developed by NASA for space flight and landings that have been applied to consumer and commercial building products and processes. Nastran, a finite element analysis program was developed by NASA and is used today throughout the world in aerospace, automotive, and maritime industries. Software was also developed for architecture permitting these exotic designs such as Frank Gehry and others but, initially, Nastran was used by PPG to develop new technology to create glass walls. NASA created all kinds of protective coatings. The Statue of Liberty restoration, a zinc silicate primer based on a 1970 NASA patent was specifically developed to provide superior corrosion protection for the iron armature. Fiberglass and teflon tension fabric roofs are an outgrowth of the material formulated by NASA from 1967 for new spacesuit fabric. A recent development that I found is an open lattice composite design allowing for lightweight, stronger structures that don’t corrode or rot. The strength comes from the efficient geometry, isosceles triangles that form a truss of pyramids which is what gives the truss it’s unique strength and stiffness.

The space age represents monumental technology and human achievements whose influence ultimately extended far beyond the space program itself. In many ways, technical innovations and materials that are synonymous with this period for exploration were disseminated to the public through a variety of consumer goods, building technologies and processes. From new alloys born out of improved mining, refining, and alloying processes to synthetic materials, engineers and labs, American design directly benefitted from the increased variety and range of properties afforded by these new materials. The architectural expression and innovative construction that resulted is increasingly becoming the charge of preservationist and conservators and we need to work with industries outside of conservation to find solutions to preserve the space age.

Thank you.

Abstract

While the influence of the machine age on architecture and design is well known, seen in the streamlining of the Art Deco and Modernist styles, the “space age” is more a cliché as a period than a true architectural influence. Design anomalies like the Sheets-Goldstein House by John Lautner exist, but they were far less ubiquitous than the esthetic of sleekness and speed that permeated many aspects of the early modern age, from railroads and aircraft to skyscrapers. Originating in Southern California in the late 1940s, Googie architecture, a form of futuristic architecture influenced by the space and atomic age, was popular into the 1960s. There was a design progression from the streamlined electric locomotives of the 1930’s, the Avanti automobile of the 1960’s, to the Space Station of the 1970’s (all designed by Raymond Loewy), but the urge to create buildings that reflected the speed of the modern age could not be sustained. The design impulse petered out after the height of the space age and we didn’t end up living in houses that looked like rocket ships.

Instead, a stronger influence on building history can be found in the transfer of materials developed for space flight into use in construction. NASA and DARPA explicitly encouraged the development of commercial uses of materials first developed for space exploration and advanced weaponry of the Atomic Age. Commonly used materials include urethane foam, honeycomb panel construction, various lightweight/high strength aluminum alloys, nickel alloys, beryllium, MylarTM, TedlarTM, RTV silicone, PlexiglasTM, and various resins. Although not visually consistent, there is a direct relationship between the research and development of titanium plates for aircraft skins used for Kelly Johnson’s A-12 and SR-71 supersonic spy planes to Frank Gehry’s titanium-covered Guggenheim Bilbao.

Just as the space-age was responsible for the creation of many modern materials that are currently in use in the building industry today, the authors are employing knowledge obtained from the treatment of mid-century modern artifacts to the conservation of mid-century building materials. A thorough understanding of these materials is critical as many have unique requirements for preservation; titanium can shatter when worked on with conventional cadmium-plated tools and the material is highly susceptible to chlorinated water or cleaning materials.

The authors have unique experience assessing, studying, testing, researching and conserving several significant Space Age artifacts including Space Shuttles, Saturn V Rockets, Skylab, a titanium A-12 spy plane, and a Corona spy satellite. Through this they have gained knowledge on the preservation of these exotic materials that can influence the treatment of these materials in an architectural setting. This paper will present examples of this research and use case studies to illustrate their findings.

This presentation is part of the Mid-Century Modern Structures: Materials and Preservation Symposium, April 14-16, 2015, St. Louis, Missouri. Visit the National Center for Preservation Technology and Training to learn more about topics in preservation technology.

Tags

- gateway arch national park

- ncptt

- mid-century modern

- mid-century modern structures

- mid-century modern structures: materials and preservation symposium

- conservation

- st. louis

- caroline guay

- conservation

- joseph sembrat

- justine p. bello

- mark rabinowitz

- nasa

- preservation

- tedlar

- space age

- titanium

- tom mcdowell