Article

Hanford: T Plant Panoramic Tour

NPS

Built during the Manhattan Project, Hanford’s T Plant was the first separations plant in the world constructed to chemically separate radioactive materials. Much of the separations work was done remotely to protect workers from the tremendous amount of radiation given off by the irradiated uranium fuel slugs. While humans had separated base and rare metals using heat and chemical processes for millennia, separating a man-made material from a highly radioactive fuel slug at an industrial scale had never been done before.

T Plant was designed to chemically separate about a half-pound (250 g) of plutonium metal from one ton (907 kg) of irradiated uranium each day. That is like separating the weight of a hamster from a mass that weighed as much as an average automobile! The chemical separations process that enabled Manhattan Project personnel to recover miniscule amounts of plutonium from the irradiated uranium were developed by University of California chemist Glenn Seaborg. His original experiments were conducted with micrograms of plutonium. T Plant’s separations processes used a billion times the amount of chemicals that Seaborg used in the lab.

US DEPARTMENT OF ENERGY

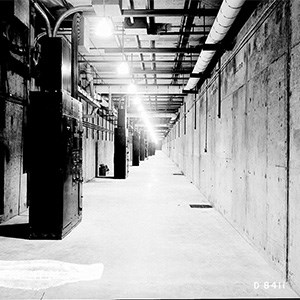

The Electrical Gallery

The T Plant building is a concrete box measuring 875 feet (266.7 m) long, 65 feet (19.8 m) wide, and 85 (26 m) feet tall. Along one side, there are three rectangular galleries: electrical gallery, pipe gallery, and the operations gallery. These galleries are stacked on top of one another and run the entire length of the building. Adjacent to and running alongside the three galleries is the canyon portion of the building, composed of 40 individual concrete cells. The chemical separations process took place in the canyon portion of the building.

The electrical gallery is the lowest level of the manned portions of the T Plant. This gallery runs the length of the building adjacent to the canyon where the chemical separations took place. This gallery contains all electrical circuitry for the operation of the building. Since T Plant has been in continuous operation since 1944, much of the electrical circuitry has been upgraded, as is obvious by the newer electrical panels you see in the above panoramic image. Many of the original panels are still in use today.

US DEPARTMENT OF ENERGY

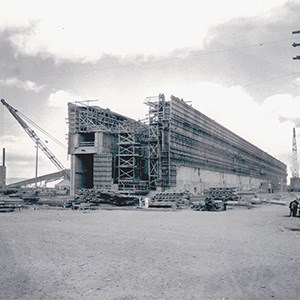

This picture shows a view of the west end of T Plant under construction. Note the thick concrete walls that protected workers from the intense radiation given off by the irradiated fuel slugs processed in the building. In the lower left is the electrical gallery, which is underground. Stacked on top of the electrical gallery is the pipe gallery. On top of the pipe gallery is the operating gallery. The space in the upper left is the “crane way” for a massive 75-ton (68 mt) capacity crane that was suspended over the canyon where plutonium was chemically separated from the irradiated uranium. The crane cab traveled the length of the building using the crane way with the actual crane sitting atop the large space in the right portion of the photo. T Plant also has an office complex and facilities where workers mixed the chemical used in the separations process.

US DEPARTMENT OF ENERGY

The Pipe Gallery

The steam, water, and various chemicals that were used in the separations process were brought into T Plant through the pipe gallery. No special shielding or procedures were required for normal operation in the pipe gallery because radioactive solutions did not pass through the pipe gallery. Radioactive materials were all contained in the canyon side of the building.

US DEPARTMENT OF ENERGY

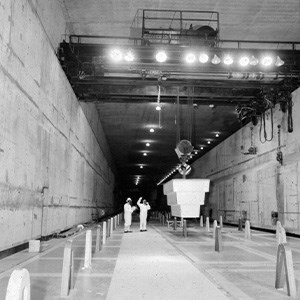

During the design of the separations building a major concern was the level of radiation that workers could be exposed to during separations activities. To reduce this hazard, the canyon was designed to be operated remotely. To accomplish that task, it was necessary to design and build equipment that could operate without direct hands-on manipulation by individuals. The result was a crane with multiple hooks and multiple capacities and equipment that could be operated using air or electrical connections such as impact wrenches and piping equipment that had impact wrench connections to open and close the valves.

The crane spanned 58 feet (17.67 m) across the canyon (pictured). The bridge, the side-to-side transport that carried the hooks for lifting equipment, across the canyon’s width, had a range of 32 feet (9.75 m), covering the working area of the canyon. There were multiple lifting hooks and hoists available that provided the crane operator with the ability to raise the cover blocks, lift equipment into and out of each cell, and remotely add and remove liquid and electrical jumpers in the cell.

US DEPARTMENT OF ENERGY

The Operations Gallery

In the operations gallery, workers remotely monitored and control the separations process in the canyon as there are no openings between the galleries and the canyon.

Gardner C. Blackburn worked as a carpenter foreman in the T Plant starting in 1943. He described a typical workday in the T Plant:

We were going all the time with several batches; once we got one going, another one would be right behind it. I had an operator on each of the boards (one for each section). Before there was any movement of the process materials from one tank to another, I had to go unlock the board. The steam went to them for jetting, and then the air blew them out to cool them off, and then we locked them up again. So I had a lot of walking up and down the gallery.

I had a supervisor who sat in the office most of the time. Of course, he would talk to the operators, but I did all the running on my shift (there were four shifts and four of us chief operators).

I had the keys and had to write in the book at the end of a shift; we always had a log, and I was responsible for filling it out. The pages in the log told the operators just how long to settle, how much and what type of chemical to put in. And then the operator had to put in that he did this, and he did that, and he did this. That’s the way we ran it.

Gardner C. Blackburn, 17-Nov-1999

US DEPARTMENT OF ENERGY

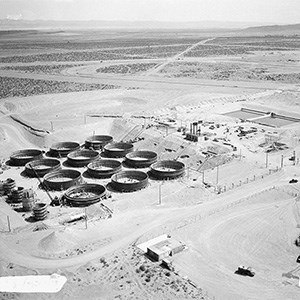

Once the plutonium was extracted, the chemically separated uranium, unwanted radionuclides, and chemicals used to dissolve the fuel slugs became liquid waste and was put into underground waste storage tanks at Hanford. The removal of liquid wastes from the chemical separations process was handled by the 241-T tank farm, a system of large-scale storage tanks, and drainage fields. At the heart of the tank farm were 12 large storage tanks each was 75 feet (22.86 m) in diameter and could hold about 530,000 gallons (2,006,268 l) with a depth of 16 feet (4.87 m). Each series of three tanks were linked together in a cascade, so that as the first tank filled, it would spill into the second tank, which would eventually spill into the third tank.

Today the waste legacy left by the Manhattan Project and the Cold War plutonium production is about 56,000,000 gallons (211,983,060 l) of highly radioactive liquid waste that in many cases has been stored for nearly 80 years and continues to be managed by the Hanford contractors under contract with the Department of Energy.

The plutonium processed at T Plant was used in the Trinity test on July 16, 1945, and in the Fat Man atomic bomb dropped on Nagasaki, Japan, on August 9, 1945. T Plant ceased plutonium separation in 1956. In 1957 it was brought back into service as a decontamination, repair, and waste handling facility. Its current mission is interim storage for radioactive sludge from a fuel storage basin near the Columbia River.

Last updated: February 9, 2024