Last updated: August 15, 2025

Article

Glossary of Weaving Terms

Like any skilled trade, there is a specialized vocabulary of terms used to talk about weaving. As you explore this glossary to learn these terms, pay attention to any words you might recognize. Many of the terms used to talk about weaving have made their way into our everyday language. Did you know ‘space shuttle’ comes from the shuttle of a loom? Like our shuttles, a space shuttle travels back and forth carrying something, only people instead of weft yarn!

Cloth Beam

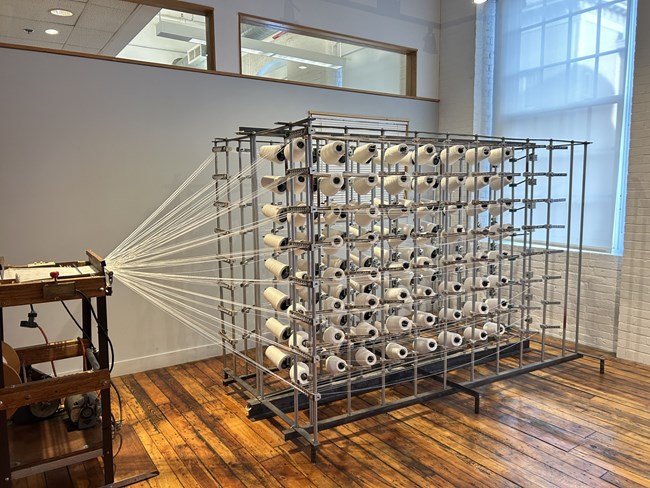

Creel

A rack that holds individual cones or spools of yarn so that many ends can be pulled out at the same time, evenly and without tangling.End

An individual warp yarn. A warp is composed of many ends, roughly the width of the cloth to be woven.

Heddle

A flat metal strip with a loop, or eye, near the center through which one or more warp ends pass on a loom. Heddles are strung on rails held at both ends by a harness frame. These are used to manipulate the threads and control the weave pattern. The shed is opened as the harnesses are raised and lowered during weaving. Heddles can also be made of wire or knotted cord.

Harness

A frame that holds the heddles in position during weaving that is attached to the loom. A harness is often called a shaft in hand weaving.

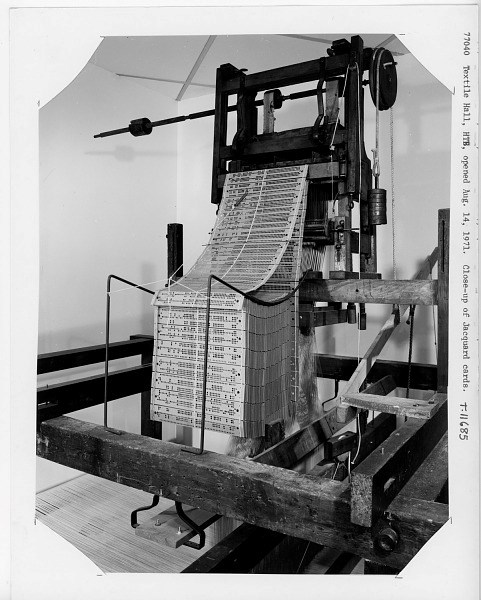

Jacquard

A specialized type of loom. A Jacquard loom uses a versatile pattern mechanism to produce intricate, often figured, designs. A pattern is programmed in by a series of punched cards. Each row on the cards represents one pick and each punched hole controls an individual warp thread, which is either raised or lowered as the card is read by the machine. Depending on the length and complexity of the design, large strings of punch cards may be needed. Jacquard weaving is used for patterned fabrics, such as brocades, damasks, and some carpets.

Loom

A machine for weaving fabric by interlacing a series of vertical, parallel threads (the warp) with a series of horizontal, parallel threads (the weft). The warp yarns pass through the heddles and reed, and the weft is shot through the shed of the warp threads by means of a shuttle (or other device) and is pushed into place by the reed and lay. The woven fabric is then wound on the cloth beam.

Reed

(Also called a beater or batten): A comb-like device, attached to a loom, that separates the warp yarns and beats each new pick against those already woven. A reed is usually made of a top and bottom rib of wood (or steel, in modern looms) into which metal strips or wires are set. Warp yarns are drawn through the dent, or space between each adjacent wire.

Selvedge

(Also spelled selvage): The vertical (running parallel to the warp) edge on either side of the woven fabric. A selvedge can be more densely woven than the rest of the cloth or made of stronger yarns to prevent the fabric from fraying or curling

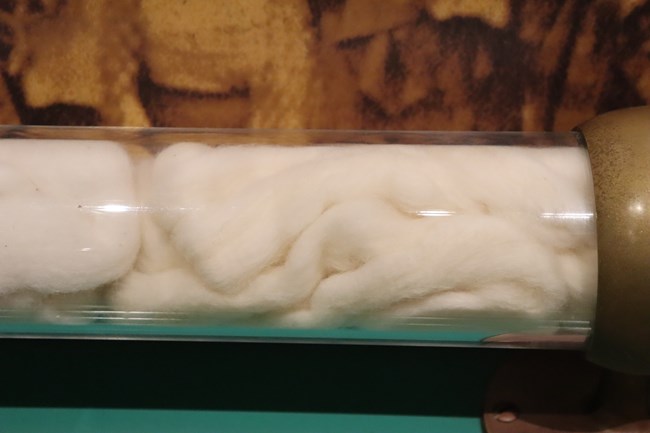

Sliver

Combed cotton fiber that has been removed from hand cards or the carding machine and split into long ropes, about the thickness of a wrist. Sliver is one of the steps in processing cotton between carding and spinning, where each progressive step makes the combed cotton thinner and longer.

Roving

Cotton sliver that has been further stretched out to be thinner and longer before it can be spun, about the thickness of a pencil, and very light twisted. Roving is the next step after sliver in processing cotton between carding and spinning. Roving is often stored in cans, shown below.