Last updated: June 12, 2024

Article

Conserving Plastics in Early Aircraft Cockpits

Plastics in Early Aircraft: Enclosing the Cockpit

by Odile Madden

Abstract

Early aviation design incorporated the most innovative plastics of the time, and examples of these technologies are represented in the Smithsonian National Air and Space Museum (NASM) collection. Particularly interesting is the co-evolution of transparent sheet plastics and the enclosure of cockpits in heavier-than-air aircraft of the 1920s through World War II. A novel, non-invasive study of goggles, helmets, and airplane canopies in Smithsonian collections was the first known large-scale technical survey of aviation plastics. It leveraged the world’s largest air and space collection as evidence of the materials and technologies used to create polymeric windows in the early-20th century.

The Wright brothers first flew at Kitty Hawk in an open architecture aircraft. By 1910, aircraft were streamlined and pilots were given some protection from the slipstream and elements by covering the aircraft’s skeletal frame with fabric, leaving the top open for the pilot’s head and shoulders. These early cockpits were located behind the engine, and the pilot was pelted with wind, rain, ice, oil, and the occasional bird that happened into the propeller. All threatened the pilot’s ability to see and maneuver the plane. Goggles and small windshields were a first defense, provided they did not fail. As flying became more common, ambitious pilots flew ever higher, faster, and year round, which brought the need to enclose cockpits and still see out of them. This period coincided with the development of shatterproof laminated safety glass and water-clear transparent plastic sheets that were lighter, more flexible, easier to shape, and less likely to shatter on impact. Aviation soon was a target market for these products.

Because the evolution of transparent window materials and plastic occurred on a similar trajectory, early aircraft – the production history of which is well known – are an opportunity to study developments in early transparent plastics. Written documentation of plastic products available at that time tends to come from manufacturers’ R&D reports, marketing materials, and advertisements, all of which offer valuable insight into what was available but may not coincide with what was used. The Smithsonian Museum Conservation Institute (MCI) and NASM teamed up to evaluate the potential of Raman spectroscopy to characterize the plastics that actually were used. Using these tools and X-ray fluorescence spectrometry we constructed a timeline for the development of aviator eyewear and aircraft window materials through World War II.

Presentation

Dr. Odile Madden: Good morning everyone. How do I move forward? Here we go.

The Wright brothers made their first powered flight at Kitty Hawk in 1903 in an open frame aircraft with the pilot lane prone. It was not long before chairs were bolted to the aircraft frame for pilots and passengers to sit in. The dangers of this configuration were obvious and exemplified by Harriet Quimby, the first licensed female American pilot, who in 19... I think I have it as 1911 here... was pitched out of her plane and killed during a demonstration flight.

By 1920 airplanes were streamlined, and pilots were given some protection from the slipstream and the elements by covering the aircraft's skeletal frame with fabric and leaving an opening or two on top for the pilot's head and shoulders. This would have improved an airplanes aerodynamics by directing the air around rather than through the plane, but the big hole on top would have been a significant source of drag. It also did little for pilot comfort and protection. These early cockpits, as they would come to be known, were located behind the engine and the pilot was pelted with wind, rain, ice, oil, and the occasional bird that happened into the propeller. All threatened the pilot's ability to see and maneuver the plane.

Kim Cullen Cobb and Odile Madden, MCI

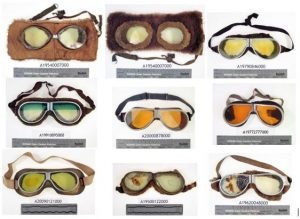

Goggles, as you can see here, and small windshields, which you do not see here, provided some protection provided they did not fail. And as ambitious pilots flew ever faster, higher, and longer distances and they carried heavier loads, the open cockpit would have become an engineering challenge. And yet cockpits were not enclosed consistently until the late 1930s.

The drawback... the central challenge was that a pilot needed to see out of a plane in order to fly. And our hypothesis was that through World War I suitable window materials did not yet exist. Other material challenges included weight, shatter-ability, and the strength to withstand fluctuating pressure and temperature.

So think about it. In 1903 the landscape of transparent sheet materials included mica, glass, and some natural and early synthetic plastics, including shellac, gelatin, and nitrocellulose, which many of you might know by the name celluloid. I'm going to be talking a fair bit about that. I'll also call it cellulose nitrate. Small windows of heat resistant mica were popular in furnaces and boilers and were later incorporated into automobiles like Ford's Model T. Plate glass was also used in automobiles, but would have been inappropriate on airplanes due to its weight and tendency to shatter on impact into sharp shards that lacerate and kill a pilot.

Strauss & Bugeleisen 1918

Now my calculation says that a quarter inch thick pane of glass, one foot square, can weigh three to eight pounds. If enclosing an airplane conservatively might've taken 20 of these, the glass alone would have added 60 to 160 pounds to the vehicle weight. For a sense of scale, the total weight of the Wright Flyer including the pilot was a mere 625 pounds, and it was moved by an eight horsepower engine. Eight. A glass enclosure would've increased the weight by... of the Flyer by 20... 10 to 26%. Now the carrying capacity of planes increased dramatically in the ensuing decades obviously, but the weight of windows in the first decades was important.

Injury from broken glass also would have been a hazard as experience showed with automobiles, which were going through a similar evolution. As with early aircraft, the first cars were open carriages without roofs or windshields. Passengers traveled in the open and relied on special clothing and gear, goggles and duster coats, to protect them from dirt and dust kicked up on unpaved roads as well as engine oil, rain, sleet, and other bad weather.

Sunset 1915

Windshields began to be incorporated onto automobiles by 1906 and were included as standard equipment on luxury vehicles as early as 1914. And this advertisement is from Sunset Magazine in 1915. Typically these were large flat sheets of plate glass that were attached to the front of the passenger compartment. And in time, the elegant vehicles enclosed on all sides with glass windows allowed people to travel more comfortably, and if this advertisement is taken for truth, without bulky over gear to protect their finery.

Now sophisticated as these were, these traveling showcases were considered a really dangerous fad. It's been estimated that 33% to 65% of automobile accident injuries were caused by flying glass. And a name came to be coined for the term for the main injury, which was called a glass necklace. And that was one's heads going through the windshield. Plate glass enclosures obviously would not have been wise for an airplane where the stakes for crashes were much higher.

Flight July 16, 1915, p. 522

So we didn't go into this project looking to write a history about aircraft enclosures. The story became interesting to us much later. We went to NCPTT because we... I'm a material scientist and a conservator, and my colleague and co-author Kim Cullen Cobb is a conservator of objects. And in conservation science we're often trying to figure out what is this material? I don't know what this thing is. And in plastics in particular we're dealing with materials that have only existed since the mid-19th century, and the evolution has been really quick. So materials that we would use today are often very different from what it would have been used then.

What was used then is often obsolete and very difficult to track down what it was, and artifacts don't come to us with manuals. So we develop techniques to identify what the materials were. I like using a technique called Raman spectroscopy. It shines light at a sample, a laser light, and a detector captures the wavelengths of light that come back to the detector. And by plotting those wavelengths, I can tell you... I can give you some idea often of what that material is for organic and some inorganic materials.

Now in around 2010 we bought a... with a generous donation... bought a portable Raman spectrometer, which you can see right there. And it weighed six pounds as opposed to the one that's behind me here, which weighs over 200 pounds. And I was thinking, okay, this is going to be a good thing to identify... to analyze plastics, but I need a test case. So in the Smithsonian collection, we must have some examples of historic plastics. It's easier if they're transparent. It's easier if they're colorless. It's easier if they're a uniform thickness. What do we have? And I was probably sitting on a plane at the time when I thought, oh, we have airplanes.

So started talking to the National Air and Space Museum about their collection. They were working on moving their collection out to a new facility at Dulles Airport, the Udvar-Hazy Center. So a lot of what we were given access to was aviator goggles, but we did get to look at some planes as well. In the end, we analyzed 87 different sets of goggles and airplane windows using our Raman spectrometers, either the one in the lab or the portable, and also X-ray fluorescent spectrometry, which tells us what elements are present in most inorganic materials.

So the study of aviation combined research of historical documents with visual examination, our Raman spectroscopy and some X-ray fluorescent spectroscopic analysis. And with that we realized that we could create a timeline of window materials used in aviation in addition to figuring out if our portable Raman spectrometer was going to be useful. Archival research and having a story also helped us deciphering the Raman spectra, which as you'll see, they're squiggly lines and they can be very hard to interpret, particularly when the composition is a mixture of materials.

And this resulted in two articles that were published in the German Journal of Raman Spectroscopy. And I got to tell you, the Journal of Raman Spectroscopy readers are not particularly interested in the history of aviation, so I'm really glad to be able to come and present to you today. I thought it was a way more interesting part of the story, but we've gotten nowhere with them.

So to give you an idea of what plastics are, because it's a material that's relatively new to most, we use it all the time, but we don't actually understand it. If somebody gave you a ring made of brass you would probably have an intuitive sense it's not gold. If somebody gives you something made out of aluminum, you're probably not going to confuse it with steel. But we're not able to do that very well with plastics yet. So a plastic is made up of a polymer. It's a very long molecule made up usually based on carbon, and polymers are not useful necessarily on their own. So other ingredients are added to the mix. And those are often plasticizers which affect the flexibility of the material and also its melting temperature, which helps in processing, a stabilizer so the stuff doesn't turn yellow and sticky and break apart as you're going to see in the early examples of plastics, fillers to make the material cheaper, colorants, etc. These are what you're going to see a lot of in the Ramen spectra. I don't think I included any of the composition information about other components.

So by 1910 the most industrial... most important industrial polymers were shellac, vulcanized rubber, and cellulose nitrate. Of these, cellulose nitrate could be fairly transparent and is known to have been used as windows for carriages in early automobiles despite a reputation for turning cloudy, scratched, and broken over time. Cellulose nitrate is less dense than glass and thus would have weighed less, probably on par with the wood used in the airplane. Now the artifact record shows that cellulose nitrate windows were used in some aircraft. One I want to see so badly is the spirit of St. Louis had... I don't know if you're familiar with that plane, but Charles Lindbergh flew without the side windows. The airplane had no front windshield, but it had side windows. And he took them out and tucked them away, and they are at the Air and Space Museum. And I sense they might be this material as well. One day I'm going to find out.

The Douglas World Cruiser Chicago however was accessible. It's one of a set of four planes that flew around the world in 1923 and that was acquired by the National Air and Space Museum soon afterwards. The cockpit was open as you can see, but some small utility windows on the wings presumably allowed for inspection of the equipment. And you can see one of those windows below or what's left of it. That one badly deteriorated window was removed from the airplane and analyzed for this study. The window had crizzled, which is a word for a lot of cracking, and fragmented and the exterior surface had taken on a light green tinge. Sorry. The exterior surface had taken on a yellow tinge, which is what you see, and the interior surface had taken on a light green tinge.

Raman spectra, which you can see there... See if I can point it out. I've got the lower... The middle spectrum is cellulose nitrate. The spectrum below that is camphor, which is a plasticizer that is needed to make cellulose nitrate into a solid sheet. And the spectrum at the top is the Douglas window. And you can see that the peaks are corresponding pretty well. This is using... in this case, this is using our FT Raman spectrometer in the lab.

This kind of problem in museums with the cellulose nitrate, it affects all sorts of objects, so not just in aviation where you see a lot of flying equipment, transparent... things for using... I'm not an aviation specialist, but things for helping read maps, for example. Those are all deteriorating, and we're losing them very quickly in collections. But why wasn't this material used more extensively in aircraft windows at the time? One possibility is it's extremely flammable, but cellulose nitrate was also a popular dope for the fabric used to wrap planes of this era, so they were already very flammable. It seems more likely that the cellulose nitrate was not used in cockpit windows even then because it was insufficiently transparent and durable.

And in the case of the Douglas World Cruiser of 1923, it was a utility window. So we can assume it was not suitable for enclosing the cockpit, or rather the potential benefit was not outweighed by the pilot's desire to fly in the open. And there you can see the spectrum at the top is what we got with the portable instrument. And you can see I've labeled the peaks... the main peaks that we use to identify cellulose nitrate and camphor.

Cellulose nitrate had more success as a laminating layer in safety glass whereby two or more sheets of glass are cemented together with an adhesive polymer such that the fragments would hold together if the window is broken. You know this from your windshields in your cars. This technology remains the industry standard for windshields and airplanes as well, although the polymer inter layer has evolved.

Now the invention of safety glass typically is attributed to a French chemist named Edouard Benedictus, who in 1930 recounted having made a serendipitous discovery in 1903, 27 years later. It's a little bit more romantic how he describes it. He was mulling over a pair of automobile accidents in which people had been gruesomely injured by flying glass, and he was reminded of a glass flask. He once had dropped in the laboratory. The flask, which was lined with a film of evaporated cellulose nitrate solution had cracked, but the glass particles had remained fastened to the dry film within.

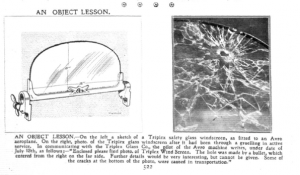

The idea germinated leading to the development of what he branded Triplex safety glass. It was a laminate composed of a sheet of cellulose nitrate plastic adhered with gelatin between two glass plates, and Benedictus supplied for the first of several American patents for Triplex in 1910. In fact, the earliest patent for laminated glass was... in automobile windows was issued to an Englishman named John Crew Wood in England. His patent was very similar, but it doesn't seem that his material was as commercially successful. So the creation myth usually goes... creation story usually is that of Benedictus's Triplex.

So his patents describe a more iterative innovation process, and this facts suggests that a fair amount of technological experimentation was taking place. In the first patent, filed in 1910, Benedictus described laminated safety glass as, "A product formed of two sheets of glass united by the interposition and sticking or pasting between them of a sheet of celluloid." He described positioning a sheet of celluloid between two sheets of glass, softening the celluloid with a suitable solvent such as acetone, and submitting the whole to a considerable pressure such as could be obtained with a hydraulic press. He also included the possibilities of multilayer laminates or a sheet of celluloid adhered to a single pane of glass and that the glass panes could be curved rather than flat. And he included substances other than celluloid.

This first patent is quite visionary and shows that he appreciated safety glass's great potential and envisioned a broad range of potential applications that have since become reality. His composite glass was intended for windows and windshields for vehicles including automobiles, cabs, carriages, omnibuses, railway carriages, boats, and the like. And though in 1910 he didn't specify aircraft... It was even...even suggested it as a deterrent to burglary. He also specified that his glass could be used for windows with quite original effects by coloring or otherwise ornamenting the nitrocellulose or the glass. And today laminated glass is still really important. There's the windshield in your car for example, but also descended technologies like architectural glass, stuff you see on skyscrapers, anti-ballistic and explosion proof glass, and even photovoltaic materials.

Benedictus followed up with a series of improvement patents that demonstrate the practical experience of the early production years, which effectively served as a period of research and development. The second patent filed only eight months after the initial describes the use of vacuum pressure rather than hydraulic pressure to compress the sandwich. This allowed for cementing curved, arched, or convex glass.

Now Triplex was expensive. There were nonstandard thicknesses of glass. They had to be defect free. You couldn't have a glass with any defect if you were going to press it because that's where it would break. And the work was done in very clean conditions, maybe not to clean room like we're used to now conditions, but very clean for the time. And in 1924 one square foot would've cost about $10 to $12. So World War I provided a major incentive for developing Triplex into airplane and automobile windshields, bulletproof glass for tanks, glass for submarines, battleship bridge windows, and eye blanks for gas masks and aviator goggles. And in particular, lenses for eye protection made economic sense because they were small.

So you can see here we've got one advertisement down at the bottom right for a windshield that has been struck by... pierced by a bullet. And you can see two images about goggles. Resist all gave you... Oh, I can't remember. I'll find... I think it gave you absolute protection and perfect vision, and it gave you unparalleled satisfaction. So yeah, this stuff was... it was a big deal.

So the one on the left however, shows a pair of shattered goggles and a similar pair of unshattered goggles. And the quote underneath is blurry, but I'll read bits of it for you. "The enclosed pair of goggles may interest you. They were worn by a late lieutenant who was unfortunately killed in an airplane accident." The caption goes on to describe a very gruesome plane crash and his demise. "The goggles were found in the condition you will find them, still in position on his face." And the letter ends, "Please let me have your price lists for goggles."

Laminated glass goggles had become popular for civilian automobile driving, were adopted by pilots for flying, and were specified by the United States War Department for pilots in 1917. In the air and space collection, laminated safety glasses found in aviator goggles of the World War I period and in airplane windshields. The fact that the lenses are laminated suggest that protection of the eyes from impacts was a concern. Other details such as a fur face pad... here. It's consistent with open cockpit flying, right? It was cold.

Other interesting features of these goggles include the tinted inter layers. So you see cyan, amber, the two toned blue and clear, which was suggested by Benedictus and intimates the importance of being able to see in a range of light... in a range of lighting conditions. And I've looked at the photos of the Wright Flyer and of Harriet Quimby, and they're not wearing goggles. So the faster you go, the more you need to protect your eyes. I also want to point out the deterioration in these goggles down here, and I'll come back to that in a moment.

We couldn't access the inner layer directly. Ramen looks with a laser. It can look into materials, but typically the instruments are designed to look at the surface. So we designed a small adaptor that fit on the end of our fiber optic probe right here, and it allowed us to... by screwing in and out the front piece, we were able to determine... we were able to fix where the laser focus would be. And if we wound it forward, we were able to look. If we wound it back, we were able to look into the glass, to the laminating layer. And if we wound it forward, we were able to just look at the glass. And here you can see the analysis being done down here.

And here are some of the spectra that we got. You can see the two very deteriorated goggles at the top. The one in the middle... the second from the bottom is also showing deterioration. And in all of those spectra you can see... I'll show the overall spectrum here. This is an artifact of the glass, but there are some little peaks right here. And this area here is blown up here for the four pairs of goggles. So you can see the peak here is consistent with cellulose nitrate, here with camphor. And that's not... it's a really noisy spectrum. It's not great. But if you have an idea that you've only got a few options given the technology of the time, that's enough to identify cellulose nitrate and camphor.

This pair of goggles here has something different. The peaks didn't match, and we didn't go on to try to identify it. But we did notice that the face... the leather components were actually pleather there. I think a PVC over a fabric. So they were faux leather, and that's all consistent with them being a later manufacturer.

Oh my God. Really?

By the 1920s the shortcomings of cellulose nitrate were well known, and safety glass inter layers were known to deteriorate within a few years of use. Several goggles in the NASM collection exhibit the deterioration I'm showing you, shrinkage and separation of glass panes.

So here's the JRS Sikorsky... JRS-1 Sikorsky. It is an amphibious aircraft that was made in 1938. And you can see by now the aircraft is enclosed. The round side windows we managed to analyze. It was the... It's the only aircraft in the air and space collection at Smithsonian that was on the ground at Pearl Harbor. This is what it looks like today. And we analyzed the laminate layer of the side windows and saw that they are actually something else. They are a cellulose nitrate layer... a cellulose acetate layer. And down there you can see the plasticized... There's something called dimethyl phthalate, and this is another plastic that's extremely unstable in museum collections.

So in 1939 a bunch of companies got together, DuPont, Libbey-Owens-Ford, Pittsburgh Plate Glass, Monsanto Chemical, and Carbide and Carbon Chemical Corporation, and they spent 6 million dollars in R&D and developed a new inner layer, which is what we use today, which is called polyvinyl butyral. And that remains an industry standard. It's a fabulous material.

Then around the same time, two Germans, Otto Rohm and Otto Haas, who founded Rohm & Haas, discovered trying to make safety glass that if they poured the plastic in... their plastic, a poly methyl methacrylate monomer, in between two sheets of glass, the glass didn't stick. It came away perfectly. And that's how we got Plexiglas, by an accident in trying to make safety glass. And they discovered in... by 1936 they had thought, oh my God, this is great for airplane windows. And they started taking out ads in magazines that they placed prominently. These are full page ads right across from the table of contents. And as best I can tell, this is the first set of advertisements for an airplane window material. But they're also specifying it for windshields and windows, which was not appropriate.

Up until that point you also see aircraft enclosures across the world, so the Japanese were doing it too, that had many small panes that could be laminated. Safety glass, maybe cellulose acetate, maybe plexi. But all of a sudden you see that with this Plexiglas revolution that you could start making nacelles, blisters, also opened the... what'd you call them? Glass cockpits? Where you could see out like this B-29 Superfortress. That's the Enola Gay.

And so you had much better visibility in war. And if you're looking here, you can see a hole. You can see a hole in that Plexiglas nose cone that here was actually for a laminated safety glass sheet that allowed... because it was flat, it didn't have the optical aberrations that Plexiglas did, so you could aim bombs and take pictures with cameras.

The last planes that we looked at were actually German all-wing aircraft that were captured... taken after World War II. These are called Hortons, named after Walter and Reimar Horten, two brothers who were aviation enthusiasts who started making plywood jets in the 1930s. And you can see here, this is a crashed one. This is a reconstruction of it. And the that canopy is in three parts. It is made of poly methyl methacrylate that we identified with our Raman spectrometer. This is the portable. The top two spectra are of each of the Hortons, and the bottom is a reference spectrum.

One thing I want to point out with the Horton for all of you who are doing preservation is that these planes are useful. You can see they're useful for other purposes than studying aviation history. They're very useful for us for understanding technology transfer, history of technology in other fields, testing out instruments. Other things that have been very interesting on this plane have been looking at the plywood manufacturer that went from natural materials like blood to phenol and urea formaldehydes, a special paint that was thought to be flame resistant polyvinyl chloride that allowed a plywood jet to not catch on fire. Although this plane never flew, it was clear the Germans were thinking about it. But there's value to keeping even these crummy looking materials because technologically they're very interesting.

Other materials started competing in the window market. So we know that cellulose acetate manufacturers were competing with Plexiglas saying that they incorporated UV stabilizers that didn't cause sunburns like Plexiglas did. Because Plexiglas lets through so much light that pilots were getting sunburned. Plexiglas was saying it's much better... easier for you to see through their material than cellulose acetate, and so competition starts. From about, I want to say 1938, you start to see in manufacturer lists in trade journals, you see lots of window companies now, whereas you saw none before 1936.

Once pilots are in... once cockpits are closed, you see goggle design change. This is a cellulose acetate design of B-8 goggle. These were interchangeable lenses that could be made in a variety of colors. I'd like to point out just this one that had... It was a polarizing plastic that had iodoquinine sulfate crystals in it, and those seem to have caused a great deal of damage in the cellulose acetate.

So conclusions. Early aviation incorporated the most advanced materials available at the time. Coevolution of aviation and plastics facilitated advances in cockpit enclosures. The enclosure in cockpits depends on material innovation that came about over several decades, and there's an iterative nature of innovation here. Museum artifacts are primary evidence of their own manufacture. And Raman spectroscopy turned out to be a very powerful tool for characterizing historic plastics, and we now use it regularly in our labs.

I'd like to thank the Museum Conservation Institute where I did this work, my current employer the Getty Conservation Institute for sending me out to give this talk, my other PI, Alex Spencer, who... at the National Air and Space Museum who allowed us to have a grant at the time, and I'd like to thank the other people on the slide, but especially the NCPTT staff who gave us this grant. Because believing in us doing something a little strange has really allowed us to advance in science in a way that I am... for which I am tremendously grateful.

Thank you.

Questions

Mary Striegel: Thank you. We have time for two questions.

Speaker 1: Hi. Thank you so much for this interesting talk. I have a question about the deteriorated aviation goggles that you're seeing.

Odile Madden: The tinted ones?

Speaker 1: No, the deteriorated.

DOdile Madden: Uh-huh (affirmative)- Yep.

Speaker 1: Is the deterioration due to physical damage that occurred prior to them being acquired by the Smithsonian or is it a direct result of the cellulose nitrate, the interleaving layer between the glass?

Odile Madden: It's the cellulose nitrate degrading, and it's a problem. So eventually it's specified that cellulous nitrate lenses could be sealed around the outside with wax, and that's to keep moisture and air out trying to prolong that life. But this was a problem. Even within a year of use it's recorded that these windshields and goggles started to fail. So it's purely chemical deterioration. What happens in museums often is that... or sometimes is that there'll be a desire to take those pieces of glass apart and get that... scrape that stuff out and put them back together. So now you've got a transparent goggle again. I'd like to point out that it's ugly, but it's very... technologically, it's very interesting. But it's a challenge. But it's definitely chemical degradation.

Anyone else? All right. Thank you.

Mary Striegel: Hang on. You’ve got a question over here.

Josie: So I don't know if you can answer this question, but maybe you can say something about it. So we know that cellulose nitrate is flammable. And if all of these museums still have these materials, for example, at the Smithsonian, are they doing any special precautionary housing or in terms of... if not housing, maybe the environment to make sure that they can still remain in the collection and maybe not just prevent deterioration, but to prevent other artifacts in the collection from possibly exploding?

Odile Madden: It's a really good question. Cellulose nitrate is the material of celluloid the film. And for those of you who've seen Cinema Paradise or Inglorious Bastards, other films, it's often a plot device that film catches on fire and kills the bad guy, kills someone you're really sympathetic towards, but cellulose nitrate film is... has legal requirements of how you must store that. You must store it in metal closed containers only so much in it... within a container to prevent spread of fire should it occur.

That has not... I believe that legal requirement does not extend to three-dimensional artifacts. And three-dimensional artifacts are usually not present in such a concentration that. It's not a full scale conflagration, but you don't want a fire starting in a store room, obviously. But they have not been discussed, I don't think, in the same legal way. And we talk about this periodically. Are we supposed to do something with these? Also, I know of no stories of an artifact catching on fire in a museum. So it's actually a really good topic for research. Thanks, Josie.

Speaker Bio

Odile Madden is Senior Scientist of the Getty Conservation Institute’s Modern and Contemporary Art Research Initiative, which aims to improve understanding and conservation of new material technologies used in nineteenth- through twenty-first-century cultural heritage. Prior to joining the GCI in 2017, she was Research Scientist at the Smithsonian’s Museum Conservation Institute, where she studied the technological evolution of early synthetic plastics to improve their preservation. She holds a PhD in Materials Science and Engineering from the University of Arizona and a MA in History of Art and Archaeology and Advanced Certificate in the Conservation from New York University.

Read other articles from this symposium, Preserving U.S. Military Heritage World War II to the Cold War, or learn more about the National Center for Preservation Technology and Training.