Last updated: January 7, 2025

Article

Building 22 Windows Restoration

Student Conservation Association photo, M. Lin.

One of the ongoing projects of the Student Conservation Association's Massachusetts Historic Preservation Corps (SCA HPC) is to repair and restore the windows of Building 22—part of the USS Constitution Museum—in the Charlestown Navy Yard. Rather than simply replacing the windows, repairing them preserves the historic material of the building and creates less waste. The project began in 2020 and will continue until all windows in the building have been restored.

Site History

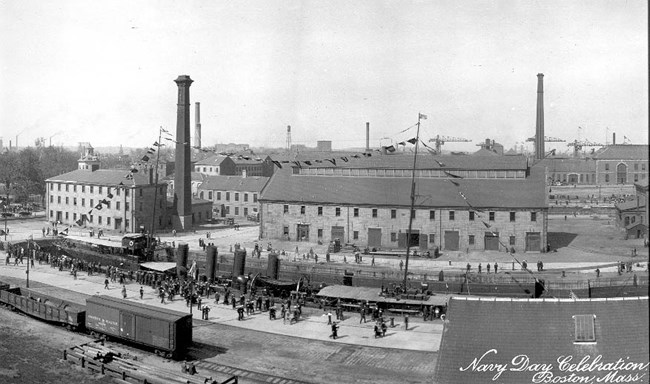

Boston National Historical Park, BOSTS-S772-2

Building 22, built in 1832, was designed by architect and engineer Alexander Parris.[1] Parris also designed several other Navy Yard structures. Building 22 served as the pumphouse for the Navy Yard's first dry dock, as well as the machine shop and blockmaker's shop.[2] In 1976, after the closure of the Navy Yard, Building 22 became home to the USS Constitution Museum.[3]

Project Overview

As wooden windows age, they degrade over time, requiring the paint and any damaged or rotting wood to be replaced. This is to both ensure that the windows do not have any further degradation, and to prevent water damage to the surrounding structure. Although replacing the old wooden windows with new, vinyl windows is a possibility, preservationists typically prefer to repair the existing wooden frame rather than replace it entirely. This practice keeps as much of the original building's material intact as possible. It also is more eco-friendly since it avoids replacing natural material with plastic.

Over 20 windows have been restored to date, with the 2024 Historic Preservation Corps crew having restored 9 of Building 22's windows.

Left image

One of the windows BEFORE restoration. March - April 2024.

Credit: Student Conservation Association photo, M. Lin

Right image

One of the windows AFTER restoration. March - April 2024.

Credit: Student Conservation Association photo, N. Kinni

Preservation Efforts

Due to decades of exposure to the elements, most of Building 22's windows were in rough shape, with heavily chipped paint, rotting wood, and cracked glass. Reversing the damage to the windows every few decades is vital to ensuring the stability of both the windows themselves and the building as a whole. Recognizing this need, the Historic Preservation Corps has stepped in to preserve the windows.

The first step of the process was to remove the windows and bring them back to the Historic Preservation Corp's workshop. As the windows had been previously painted with lead paint, crew memers had to take special precautions to remove the windows. They laid down plastic sheeting around the windows and instituted proper cleanup procedures to prevent the spread of stray lead paint chips.

Student Conservation Association photo, R. Davis

Upon their arrival at the shop, the windows were organized and individually assessed for any specific repairs or replacement parts they needed.

Student Conservation Association photo, N. Kinni

The crew removed the lead paint using paint scrapers and heat guns, wearing proper equipment—such as respirators and safety goggles—to prevent lead contamination. After they stripped the paint and removed the glass panes, crew members made any necessary wood repairs. Smaller holes were filled with wood filler. More intense damage, such as rotting wood, required the crew to make dutchman repairs, in which the original, damaged area of wood is cut off and replaced with a newly-cut piece of wood matching the original frame.

Student Conservation Association photo, M. Kaiser

After they completed all wood repairs, crew members cut replacement glass and secured the panes to the wooden frame using metal fasteners and glaze, a clay-like material that hardens over time. Once the glaze dried, crew members painted the windows with one coat of primer and two topcoats before bringing the windows back to the site for reinstallation.

Student Conservation Association photo, A. Lueth

Contributed by: Greg Bsales, SCA Historic Preservation Corps Crew Member

Footnotes

[1] Stephen P. Carlson, Charlestown Navy Yard Historic Resource Study vol. 1. Boston, MA: Division of Cultural Resources, Boston National Historical Park, National Park Service, US Department of the Interior, 2010, 38. NPS History.

[2] Stephen P. Carlson, Charlestown Navy Yard Historic Resource Study vol. 1. Boston, MA: Division of Cultural Resources, Boston National Historical Park, National Park Service, US Department of the Interior, 2010, 33-38, 60. NPS History.

[3] Stephen P. Carlson, Charlestown Navy Yard Historic Resource Study vol. 1. Boston, MA: Division of Cultural Resources, Boston National Historical Park, National Park Service, US Department of the Interior, 2010, 177. NPS History.