|

KATMAI

Fure's Cabin Historic Structure Report |

|

III. APPENDIX

B. PREVIOUS FIELD NOTES

United States Department of Interior

NATIONAL PARK SERVICE

Denver Service Center

755 Parfet Street

P.O. Box 25287

Denver, Colorado 80225

IN REPLY REFER TO:

H30-DSC-MH

Sep. 3, 1975

Memorandum

To: Superintendent, Katmai National Monument

From: Robert Carper, Historical Architect, Historic Architect Branch, Historic Preservation Division, Denver Service Center

Subject: Fure's Cabin Floor Stabilization

I wish to thank you and the Park staff for the assistance you provided during my recent visit to conduct the survey for the List of Classified Structures program. My report on the findings for Katmai should be complete in the near future.

As you recall, during our discussion of Fure's Cabin, I had volunteered to forward to you suggestions for the stabilization of the floor. Enclosed is a brief description of the approach for the work; however, these suggestions should be considered in light of conditions unique to Katmai. Mike Shapsnikoff has the experience in local construction techniques and climatic factors and can undoubtedly be the best judge on the materials and methods. A copy of our suggestions is being sent to the Regional Associate Director for Professional Services and to the Alaska State Office. Before taking any action, Regional concurrence should be solicited since the building may be eligible for National Register listing and subject to compliance procedures.

We would be interested in your findings and results of the stabilization work and hope the suggestions are helpful. Your efforts to preserve the structure will surely be appreciated by present and future Park staff who use the cabin on patrols as well as visitors who will be able to visualize the history of the Park.

Robert L. Carper

Enclosure

cc:

Assoc. Reg. Director, PS, PNR

State Director, Alaska State Office

Floor Stabilization Suggestions

Fure's Cabin

Katmai National Monument

Description

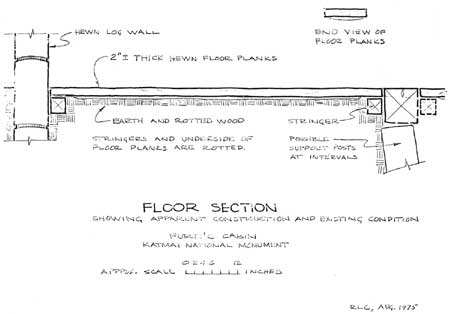

The southeasterly or front half of the wood plank floor of the cabin has settled and become uneven, probably caused by both rotting and settling of the plank supports. The floor is pitched and uneven and at one location there is perhaps a 4 inch difference from the surface of one plank to the adjacent one. A brief investigation at this location gave some clues as to the construction of the supporting members of the flooring. The attached sketches show possible constructions, but these remain in part, conjecture, as only a small area beneath the planks could be felt.

If in the original construction an air space was provided below the floor, it is now for the most part filled with dirt and rotted wood particles. The underside of the floor planks were hewn flat at each end to provide full bearing area on stringers or ledgers running the length of the cabin, one at the wall and one at the longitudinal center beam. A post was evident under the stringer or ledger; there may be others spaced along its length. However, this post may have been for support of the longitudinal center beam, and is out of place. If such is the case, it seems possible that the plank supporting member may have been a ledger nailed to the center beam. Or rather than a ledger board, the center beam may have been cut to provide bearing for the floor planks.

Initially, dismantling and inspection of this section of the floor will permit the maintenance staff to determine the construction and replacement materials needed. Much of the material preparation can then be done in the shop at Brooks Camp to minimize transporting of equipment to the site in the boat.

Methods and Materials

The coated canvas-like covering on this part of the floor is partially gone. Assuming it is bonded in some manner to the planks, it may not be removable without special techniques. Thus, if it cannot be rolled back for reuse of any remaining portions, it may have to be cut along the edges of each plank and allowed to remain.

Each plank should be numbered for positioning with a marker that can be removed or will not be seen. Take up the planks and remove major rot from undersides. Inspect planks to determine those that cannot be reused.

Remove sufficient earth and rotted wood particles to provide an air space below the planks when replaced. Disposal of this material should be in a manner and location to be unobtrusive.

Inspect construction and condition of plank support system to determine what must be replaced. Take measurements for replacement members.

New members can be precut at Brooks Camp and treated with a pentachlorophenol preservative. If feasible, it would be preferable to soak the members in a tank for at least 30 minutes. If not, they should be thoroughly drenched by brushing or spraying, two applications given at least 24 hours apart. Original planks being reused should be allowed to dry before application of preservative. (Note: The preservative may remove the canvas floor covering, in which case a sample should be retained for future reference prior to preservative treatment.) Allow to dry and remove any surface residue before transporting to the cabin.

If bearing for stringers is inadequate, it may be desirable to put in a bed of beach gravel or sand under wood blocking or rock supports. Set and secure new stringers and/or ledger boards. An additional stringer should be placed under the planks at mid-span since the rot has reduced the effective thickness and the earth no longer will support them. (Consideration was given to laying in a 6 mil minimum thickness polyethelene moisture barrier, bringing up vertically against the walls and center beam. However, this standard approach may be detrimental by trapping moisture within the air space under the planks.)

Replace original and new planks in their proper locations and secure in the same manner as originally done (if any).

|

| (click on image for a PDF version) |

| <<< Previous | <<< Contents>>> | Next >>> |

katm/fures_cabin/appb.htm

Last Updated: 26-Mar-2008