Springfield Armory’s Building 104: The M1 “Garand” Rifle Production FacilityLocated across Federal Street from Armory Square (Springfield Armory National Historic Site), Federal Square was an imporant site throughout the Armory's history. The site was the location of the Continental Powder Magazine and Ordnance Yard during the American Revolution and the site of a pitched battle during Shays' Rebellion in 1787. Beginning in the 1890s. the site was transformed into a major manufacturing site for Springfield Armory. The world-famous M1 rifle was manufactured in a state-of-the-art facility, Building 104, ensuring that the US soldier had the most superior rifle as the country entered the Second World War. Today, the site is a successful commercial site, training facility, and small business incubator.

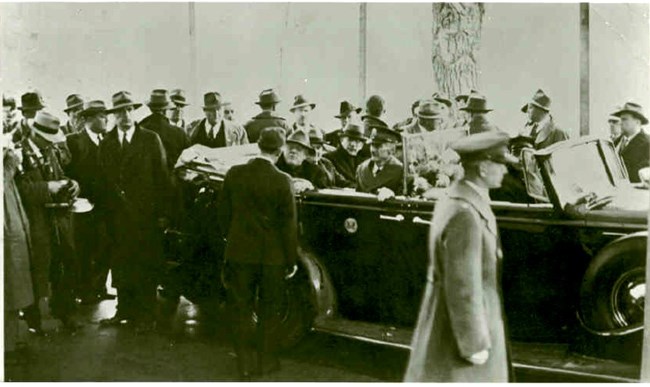

Photo Credit: Springfield Armory NHS Archives Taking the form of a large state-of-the-art production building, a city block in length along Magazine Street with 135,000 square feet of floor space, it was expected to double daily production of the new M1 “Garand” Rifle by the following summer – and none too soon just months before the Japanese attack on Pearl Harbor. Seeking to encourage this build-up at the Armory, President Franklin D. Roosevelt arrived October 30, 1940, attracting a record crowd for a speech at the Armory. That day, John Garand, inventor of the M1 Rifle, personally presented to FDR a completed rifle just off the assembly line (On display at the Museum). Armory superintendent Brig-Gen. Gilbert H. Stewart accepted the completed manufacturing building for the US ARMY two months later knowing that the keystone was in place to bring together the Armory’s swelling ranks of skilled workers with the raw materials and machines to place into the hands of the American serviceman the finest semi-automatic military rifle ever made.

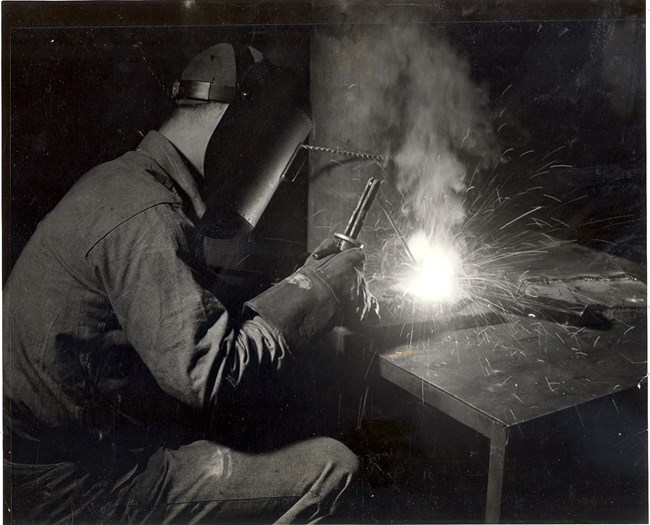

Photo Credit: Springfield Armory NHS Archives Within three short months, Building 104 was designed, engineered, and erected, attracting engineers from across the Nation. In February 1941, the new Milling Shop was ready. Production machines were moved in the dead of winter from the Water Shops and operational in less than two hours, averaging a loss of only four hours production time for each machine moved. This modern factory, housing tanks for coolants and lubricants, modern lighting (First in the Nation, electrical power, and ventilation, came to symbolize at the time the rebirth of the Armory.

When construction began, Springfield Armory produced 200 M1 rifles per 8-hour day. One year later, shortly after completion of Building 104, production increased to 1,000 per 8 hour day with a fivefold increase in output during fiscal year 1941 - justly a source of pride for Armory workers. By the time the United States formally declared war in December 1941, the number increased to 1,100 per 8-hour day. Production of the M1 “Garand” continued to accelerate to greater levels, thanks to the men and women working in Building 104, to more than 3,719,000 rifles by the end of the war – nearly a million a year! This is the rifle General George S. Patton called “the greatest battle implement ever devised.” Thousands of people worked in Building 104 through the years, but perhaps no group felt as much urgency, pride, and purpose as those who worked on the M1 rifle during the Second World War.

Photo Credit: Springfield Armory NHS Archives Walter Moczarski started at the Armory on January 2, 1940, and started working in Building 104 as soon as it was finished a year later. During the war, he was a set-up man for production. He worked with a team of 12 women, ensuring their machines were tuned, cutters were sharp, and the machine was able to perform for the night shift. (SPAR Oral History 92-1) Louise Speliopoulos was a student at Commerce High School when she went to work for the Armory, which was her first job outside of her father’s business. She worked first shift during the summer of 1943. She worked on a milling machine making butt-plates for the M1 rifle. Occasionally, she would visit the nurse’s station to tweeze out steel slivers from her hands. (SPAR Oral History 86-8)

Following the war, Building 104 again demonstrated the payoff for its modern open and flexible design as it continued to host modern and innovative manufacturing technologies. Within a few years, a production line for new vacuum-packing of weapons in metal containers for indefinite storage and immediate distribution was created. Better stock and rifle machinery was devised and installed, as well. Here, too, witnessed the early pioneering efforts and the eventual maturity of modern digital computer-programmed machining technology – without which America’s competitive edge in precision production would not be possible. Today, Smith & Wesson’s CNC machine production is a direct beneficiary of what occurred in the Armory’s Building 104. And, after all, what would one expect from an Armory legacy that includes nearly two centuries of advanced pioneering precision production starting with the 1820s Blanchard lathe that produced musket stocks by machine |

Last updated: August 19, 2021