Last updated: June 29, 2018

Article

Common Problems with Brick Masonry

Monitoring

Exposed masonry should be inspected periodically for cracking, spalling, bowing (vertical bulges), sweeping (horizontal bulges), leaning, and mortar deterioration. Before beginning a detailed masonry inspection, determine which walls are loadbearing and which are not. Usually this can be done by examining the beams and joists in the buildings basement or crawl space or attic. Note also whether the walls are solid masonry or masonry cavity, or whether they are non-structural brick or stone veneer.

Example of a common wall crack which follows the brick in a stair-step pattern. This type of movement was probably caused by thermal or moisture expansion.

National Park Service

Thermal Cracking

Although masonry can deform elastically over long periods of time to accommodate small amounts of movement, large movements normally cause cracking. Cracks may appear along the mortar joints or through the masonry units. Cracking can result from a variety of problems: differential settlement of foundations, drying shrinkage, expansion and contraction due to ambient thermal and moisture variations, improper support over openings, the effects of freeze-thaw cycles, the corrosion of iron and steel wall reinforcement, differential movement between building materials, expansion of salts, and the bulging or leaning of walls.Above-ground brick walls expand in warm weather (particularly if facing south or west)

and contract in cool weather. This builds up stresses in the walls that may cause a variety of cracking patterns, depending on the configuration of the wall and the number and location of windows and doors.

Such cracks (Figure 1) are normally cyclical and will open and close with the season. They will grow wider in cold weather and narrower in hot weather. If possible, monitor such cracks over a period of time to see if they’re active. Active cracks should be sealed with a flexible sealant; inactive cracks may be pointed.

Wall Cracking or Displacement Associated with the Structural Failure of Building Elements

Structure-related problems, aside from those caused by differential settlement or earthquakes, are usually found over openings and (less commonly) under roof eaves or in areas of structural overloading. In these instances, the masonry units will show cracks through the units themselves rather than along the weaker mortar joist. Typical displacementissues include:

- Cracking or displacement of masonry around openings, resulting from the deflection or failure of the lintels or arches that span the openings, or displacement due to overstressed masonry units. In older masonry walls with wood lintels, cracking will occur as the wood sags or decays. Iron and steel lintels also cause cracking as they deflect or rust over time. Correcting such problems usually means replacing failed components and rebuilding the area around the opening with additional reinforcing.

- Cracking or outward displacement under the eaves of a pitched roof due to failure in (or lack of) the horizontal roof ties that results in the roof spreading outward. The lateral thrust of the roof on the masonry wall may cause it to crack horizontally just below the eaves or to move outward with the roof.

The weight also can be transferred to interior walls. Jacking of the ridge (if one exists) and rafters is possible too.

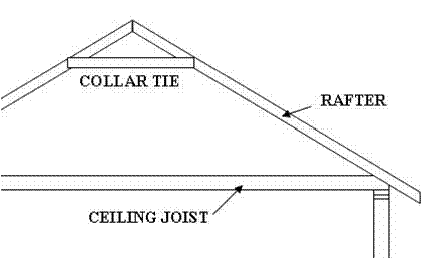

Typical roof framing.

Photo courtesy of www.diychatroom.com.

An examination of the attic over the main portion of a building should disclose the presence (or absence) of a ridge rafter and collar ties (Figure 2). It is likely that snow loads might overstress the roof causing the masonry walls to start to buckle outward, causing structural cracking.

- Cracking due to overloading (or interior movement), which is fairly uncommon, may be caused by a point load (often added during an alteration) bearing on a wall of insufficient thickness.

National Park Service

Pointing

Once the nature and source of cracks has been determined, the next step is repair. Structural repairs precede minor or cosmetic repairs. Repointing mortar joints is often required, however, this action requires care and is best done with professionals familiar with historic masonry techniques. All too often, more damage is done to historic brick buildings with improper pointing than most any other treatments. And the damage is not only cosmetic. Care must be taken to match the properties (color, hardness, permeability) of the existing mortar. Hard mortars (those with high concentrations of portland cement) are less permeable than surrounding brick, and with both differential movement and differences in moisture permeability, will often cause the surrounding masonry to deteriorate or deteriorate faster. The application must also be carefully controlled. Width of joints and tooling should match the historic appearance, and care must be taken in application and cleanup to ensure that mortar does not extend past the joints of individual units and onto the surface of bricks. From a distance this latter action is most bothersome – the wall changes from a uniform to a mottled appearance. National Park Service (NPS) Preservation Brief No. 2: Repointing Mortar Joints in Historic Masonry Buildings is an excellent guide for this work: http://www.nps.gov/history/hps/TPS/ briefs/brief02.htmCoating

A severely deteriorated brick wall will often cause an owner to consider coating the wall with a waterproofing substance or paint in an attempt to improve its appearance and/or arrest deterioration. A brick wall that has deteriorated to the point that it has become unsightly has probably received a treatment that caused the loss of the wearing surface of the brick. Often that treatment was an abrasive cleaning method (such as sandblasting). The blasting operation causes the loss of the outer, hard surface of the brick, exposing the softer core. Water, the most destructive force on historic masonry surfaces, can then wick into the brick cores, and if in a northern climate where winter freezes are prevalent, will cause the brick to deteriorate from freeze-thaw action.Waterproofing the brick either with chemicals sold for this purpose, or by painting with non-permeable paint or other coatings will accelerate the decay by trapping moisture behind the new coating.

If it is absolutely necessary to coat a brick wall, a water-permeable coating will work best, but if a wall is this deteriorated and has not been abrasively cleaned, a closer assessment of its deterioration is warranted. NPS Preservation Brief No. 1: Assessing Cleaning and Water-Repellent Treatments for Historic Masonry Buildings; and No. 6: Dangers of Abrasive Cleaning to Historic Buildings are excellent sources of information.

Originally published in "Exceptional Places" Vol. 3, 2008, a newsletter of the Division of Cultural Resources, Midwest Region. Written by Mark Chavez.