Last updated: March 30, 2023

Article

Building America's Industrial Revolution: The Boott Cotton Mills of Lowell, Massachusetts (Teaching with Historic Places)

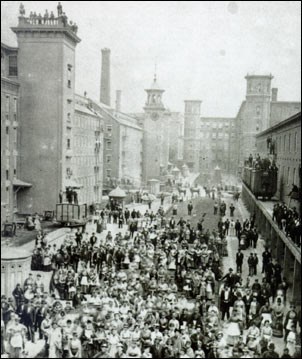

(Lowell Museum Collection/Lowell Historical Society)

This lesson is part of the National Park Service’s Teaching with Historic Places (TwHP) program.

Like a medieval fortress or great cathedral, the structure dominates all that is around it. A great wall separates it from the Merrimack River. Within that rampart, thick, red brick walls, punctuated by windows of many shapes and sizes, rise from the ground, surrounding interior courtyard spaces that can be entered only by crossing a single bridge over the deep water of a canal. Brick or wood stair towers placed along the exterior of the walls provide the only means of entry to upper floors. A single bell tower dominates the central courtyard.

For more than 100 years the bell called people to this place on a daily basis, not to protect the city from invaders or to worship, but to work. The sounds from the complex were not those of battles or church choirs, but of machinery clanking and rumbling 10 to 14 hours a day. Rushing water ran water wheels and turbines, and bells constantly clanged to regulate life's daily activities. This was the Boott Cotton Mills complex at Lowell, Massachusetts. It was typical of what some call a "cathedral of industry" where people from all over the world toiled for the single purpose of mass-producing a consumer product: textiles.

The Boott Cotton Mills complex contains mills built from the mid-1830s to the early 20th century, reflecting the early use of waterpower, steam power, and finally electric power. Changes in technology and production capability influenced the development and appearance of the millyard over time. In essence, the Industrial Revolution's transformation of America from an agrarian-based society to an industrial society can be seen through the physical development of the Boott Cotton Mills from 1835 through the early 20th century. Today, the restored mill complex houses the Boott Cotton Mills Museum, a part of Lowell National Historical Park.

About This Lesson

This lesson is based on the National Register of Historic Places registration file, "Lowell National Historical Park" (with photographs) and other source material about this millyard, as well as other industrial sites in Lowell. It was written by Stephen Stowell, a former Park Ranger, at Lowell National Historical Park who is now Administrator of the Lowell Historic Board. TwHP is sponsored, in part, by the Cultural Resources Training Initiative and Parks as Classrooms programs of the National Park Service. This lesson is one in a series that brings the important stories of historic places into the classrooms across the country.

Where it fits into the curriculum

Topics: The lesson could be used in units on America's Industrial Revolution and in other related disciplines such as science and the history of technology. Students will strengthen their skills of observation, analysis, interpretation related to history, geography, the social sciences, and architecture.

Time period: Early to mid-19th century

United States History Standards for Grades 5-12

Building America's Industrial Revolution: The Boott Cotton Mills of Lowell, MA

relates to the following National Standards for History:

Era 4: Expansion and Reform (1801 to 1861)

-

Standard 2A- The student understands how the factory system and the transportation and market revolutions shaped regional patterns of economic development.

-

Standard 2B- The student understands the first era of American urbanization.

-

Standard 4C- The student understands changing gender roles and the ideas and activities of women reformers.

Curriculum Standards for Social Studies

(National Council for the Social Studies)

Building America's Industrial Revolution: The Boott Cotton Mills of Lowell, Massachusetts relates to the following Social Studies Standards:

Theme II: Time, Continuity and Change

-

Standard C - The student identifies and describes selected historical periods and patterns of change within and across cultures, such as the rise of civilizations, the development of transportation systems, the growth and breakdown of colonial systems, and others.

-

Standard D - The student identifies and uses processes important to reconstructing and reinterpreting the past, such as using a variety of sources, providing, validating, and weighing evidence for claims, checking credibility of sources, and searching for causality.

Theme III: People, Places, and Environment

-

Standard I - The student describes ways that historical events have been influenced by, and have influenced, physical and human geographic factors in local, regional, national, and global settings.

Theme VII: Production, Distribution, and Consumption

-

Standard A - The student gives and explains examples of ways that economic systems structure choices about how goods and services are to be produced and distributed.

-

Standard I - The student uses economic concepts to help explain historical and current developments and issues in local, national, or global contexts.

Theme VIII: Science, Technology, and Society

-

Standard B - The student shows through specific examples how science and technology have changed people's perceptions of the social and natural world, such as in their relationships to the land, animal life, family life, and economic needs, wants and security.

-

Standard C - The student describes examples in which values, beliefs, and attitudes have been influenced by new scientific and technological knowledge, such as the invention of the printing press, conceptions of the universe, applications of atomic energy, and genetic discoveries.

Objectives for students

1) To compare the initial and later power sources of the Boott Mills and explain why they changed.

2) To compare the appearance of earlier mills, such as Slater's Mill, with those constructed in the Boott millyard to see how industrial design changed over time.

3) To explain how function influenced mill design.

4) To discover how the Boott millyard was changed to increase production.

5) To identify the types of industry and industrial structures (factories, mines, bridges, dams, canals, etc.) that exist in their own community or region and to explore how these industries were alike and different from the Boott Cotton Mills.

Materials for students

The materials listed below either can be used directly on the computer or can be printed out, photocopied, and distributed to students. The maps and images appear twice: in a low-resolution version with associated questions and alone in a larger, high-resolution version.

1) Two maps of Massachusetts and Lowell's canal system;

2) Three readings compiled from historic studies and primary documentation on the physical and technological development of the Boott millyard;

3) Five drawings that illustrate the evolution of the site;

4) One historic photo of the Boott Mill complex.

Visiting the site

Lowell National Historical Park, administered by the National Park Service, is located 30 miles northwest of Boston, Massachusetts. The park includes historic cotton textile mills, 5.6 miles of canals, operating gatehouses, and worker housing. Trolley and boat tours run seasonally, while interactive education programs are presented in cooperation with the University of Massachusetts, Lowell's Tsongas Industrial History Center during the school year. The Boott Cotton Mills Museum includes an operating early 20th-century mill weave room of 88 power looms. The Working People Exhibit is located in a former mill boardinghouse. The park is closed New Year’s Day, Thanksgiving Day, Christmas Eve, and Christmas Day. For more information, contact the Superintendent, Lowell National Historical Park, 169 Merrimack Street, Lowell, Massachusetts 01852, or visit the park's web pages.

Getting Started

Inquiry Question

(Courtesy of American Textile History Museum, Lowell, Mass.)

What might this structure be?

What product do you think it produced?

Setting the Stage

The Boott Cotton Mills, constructed from 1835-c. 1910, was one of many cotton textile mill complexes established in the growing city of Lowell, Massachusetts. It represents one of the oldest surviving textile mill complexes in the United States. Boott Cotton Mills' buildings were products of the earliest large-scale industrial planning project in America and were developed by the same industrialists who founded the city of Lowell. Among the planners was Kirk Boott, first agent of the initial textile company in Lowell, for whom the Boott Mills are named.

The Boott millyard is regarded as one of the most architecturally significant millyards in the United States. The four mills and the counting house were constructed in the 1830s. They survive as part of an interconnected series of mill buildings built over a 75-year period. The Boott millyard illustrates the development of a single textile company in the early years of America's Industrial Revolution and how it paralleled the rise and decline of the Northern textile industry.

Locating the Site

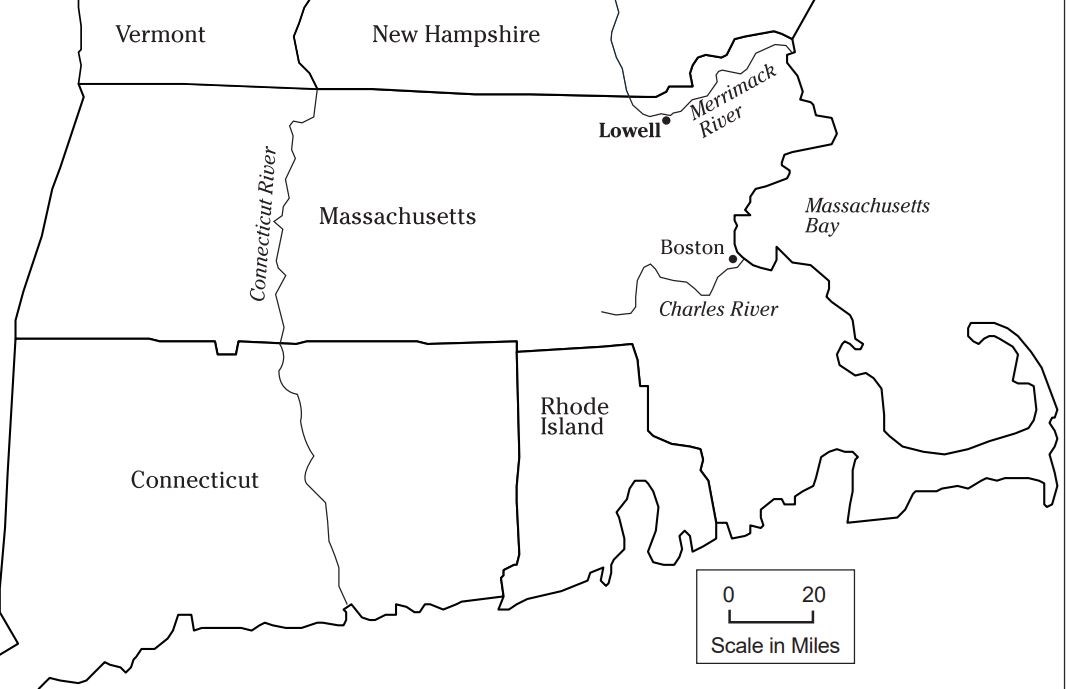

Map 1: Massachusetts & surrounding region.

Questions for Map 1

1. Note the location of Lowell, Massachusetts. How do you think raw materials needed for textile manufacture and finished textiles were transported between Lowell and Boston as well as other cities in the 19th century?

Locating the Site

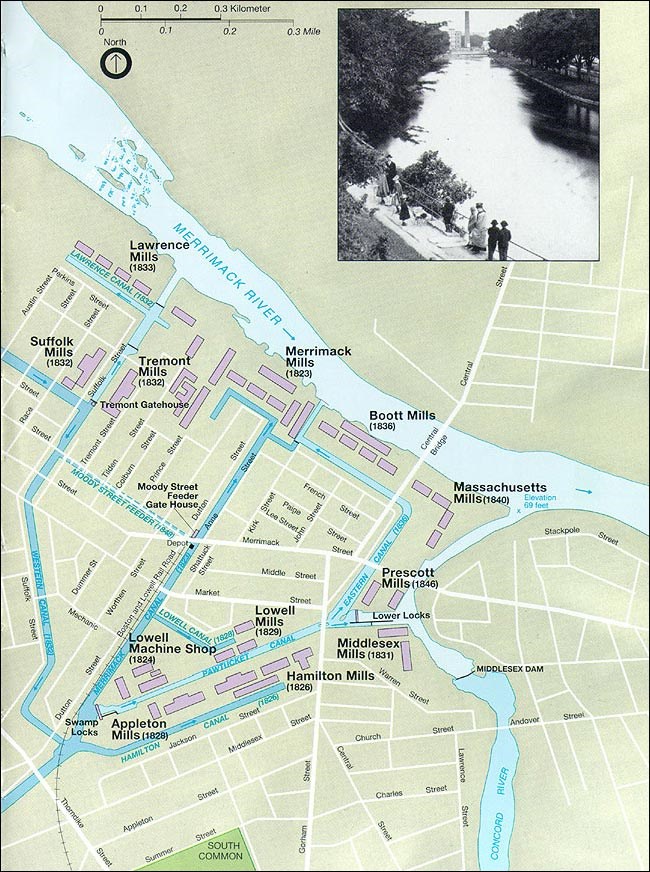

Map 2: Lowell's canal system in 1850.

(Lowell National Historical Park)

In planning Lowell, the primary objective was to place each mill in a location to take advantage of waterpower. The sites chosen were contained within or adjacent to the eastern half of an irregularly shaped island formed by the Merrimack River and the Pawtucket Canal. Feeder canals were extended from the Pawtucket Canal to the mill sites which were located parallel to either the river or canals. Power was transmitted from the canals to the mills first by water wheels and later by the more efficient water turbines that began to be installed by the late 1840s. By the late 1830s, increased demands for waterpower were beginning to produce shortages. Continued industrial growth was contingent upon an increased supply of waterpower. In 1847 the construction of the Northern Canal, an alternative waterway connecting the Merrimack River to the Western Canal, improved the quantity and efficiency of waterpower and prompted further growth in the productive capacity of Lowell.¹

Questions for Map 2

1. Locate Boott Mills. Between what two waterways was the Boott Mills complex situated?

2. How many mill complexes are indicated on the map? How many of these were constructed before Boott Mills? What does this indicate about Lowell's importance as an industrial site?

Determining the Facts

Reading 1: The Industrial Development of Lowell

In 1814 on the Charles River in Waltham, Massachusetts, a group of Boston investors introduced the first integrated cotton textile mill. Here each step in the production of cloth from bale to bolt took place under one roof with machinery powered by water. Management also turned to an innovative source of labor, the daughters of New England Yankee farmers. The success of the "Waltham Experiment" encouraged investors to explore other sites on which to expand and print calico cloth. In 1821, they chose an area around the Pawtucket Falls on the Merrimack River at East Chelmsford, Massachusetts. This site became Lowell, the first large, planned, industrial city in America. The system of factories and power canals created here surpassed previous engineering schemes in both scale and level of sophistication.

At the Pawtucket Falls, the Merrimack River fell 32 feet over a series of drops and rapids in the space of one-half mile. In 1796, a company called the Proprietors of Locks and Canals on Merrimack River built the Pawtucket Canal, as a transportation canal, to bypass these falls. The Boston investors purchased the Proprietors of Locks and Canals and some 250 acres of adjacent farmland for development in 1821. Between 1822 and 1848, they rebuilt Pawtucket Canal into a feeder canal. They planned and constructed a dam at the head of the falls, seven power canals, and 10 large companies consisting of more than 50 mill buildings, including two print works, a bleachery, and a machine shop. They also provided schools, churches, libraries, and housing for their workers. During this period, Lowell's population grew from about 2,500 to 33,000.

Lowell became America's model industrial city during the first half of the 19th century. Lowell offered the hope that the country would profit socially as well as economically by adopting industrialism as a way of life. The early Lowell system was distinguished by its state-of-the-art technology, the engineers and inventors who worked on its canal system, its mill architecture, enormous production capabilities, rational city planning, and most of all, by its much-heralded workforce of Yankee "mill girls."

Throughout the 19th century wave after wave of immigrants--Irish, French-Canadian, Greeks, Polish, and Portuguese--arrived in Lowell looking for job opportunities in the expanding textile industry. During this period Massachusetts implemented reform legislation affecting child labor, education, and working conditions which cut investors' profit margins. In the 1920s rather than reinvesting in aging Northern textile factories with high taxes, union labor, and expensive transportation costs, investors turned to new textile plants in the South. As a result many of the textile companies in Lowell closed or moved south. A few companies diversified or produced specialized products. After the 1920s, except for occasional economic boons such as World War II, Lowell experienced some of the highest unemployment rates in the country until the 1970s.

Lowell is not, as is sometimes claimed, the birthplace of the Industrial Revolution in America. Most of the developments associated with this phenomenon in the nation's history had their origins elsewhere. But it was at Lowell that these developments converged in a way that made them revolutionary. New forms of technology, power generation, finance, labor, and industrial organization were combined on a scale that foreshadowed today's industrialized and urbanized society.

Questions for Reading 1

1. What conditions at the Merrimack River did Lowell's early industrialists use to their advantage?

2. Besides mills, what were other important elements of the industrial planning at Lowell?

3. What were some of the reasons for the decline of the Lowell textile mills?

Reading 1 was compiled from Charles Parrott, Industrial Heritage 1984 Guidebook: Lowell Excursion, The Fifth International Conference on the Conservation of the Industrial Heritage, 1984; and Robert Weible, "Lowell National Historical Park" (Middlesex County, Massachusetts) National Register of Historic Places Registration Form, Washington, D.C.: U.S. Department of the Interior, National Park Service, 1985.

Determining the Facts

Reading 2: The Mill as a System

The typical Lowell textile mill consisted of an integrated sequence of mechanized processes which transformed raw cotton into finished cloth. The system drew on diverse people and skills to make it work. Factory owners, workers, agents, overseers, machinists, millwrights, checkers, and boardinghouse keepers together with machine belts, shafting, water wheels, turbines, lighting and fire safety equipment, even the building itself were all parts of an immense and complex process of interrelated functions. Viewed in its broadest perspective, the Lowell factory system reached far beyond the city limits. Vital raw material was shipped from the American South, and finished textile products could be found in all sections of the United States, Europe, Central America, Canada, and even China. Included in this system, broadly conceived, were railroad workers, seamen, plantation owners, slaves, sales agents, retail merchants, and cotton factors. From a more limited perspective, the factory system encompassed every aspect of activity confined within the walls of a given mill.

Two central components of the Boott Mills, and others like the Boott, were the power system and the production system. There were several other subsystems such as communications, lighting, heat and humidity, sanitation and safety, fire prevention, transportation, maintenance and repair, machine building, architecture and construction, management, and labor which were vital parts of the whole. Changes in these subsystems affected both power and production; in turn, innovations in either the power system or the production system affected the subsystems. As a result, many of the innovations and changes inherent in the founding and development of the factory system brought unanticipated consequences. The factory system was a process where change was the order of the day and in which the whole was greater than the sum of its parts.

Questions for Reading 2

1. What was the end product of the mill system? How do you think this product was made before mills were built?

2. In the broadest sense, the mill system stretched far beyond a single factory or factory complex. What outside forces had an impact on the functioning of the mill?

3. In addition to the power and production systems, what other subsystems were vital parts of the mill?

Reading 2 was adapted from the "Mill As A System: Developing the Interpretive Program and Three Historical Essays on 19th Century Lowell," unpublished exhibit planning report for the Boott Mills Area, Lowell National Historical Park, by the Center for History Now, Williamsburg, Virginia, September 1983.

Determining the Facts

Reading 3: Forms and Structures of the Textile Industry

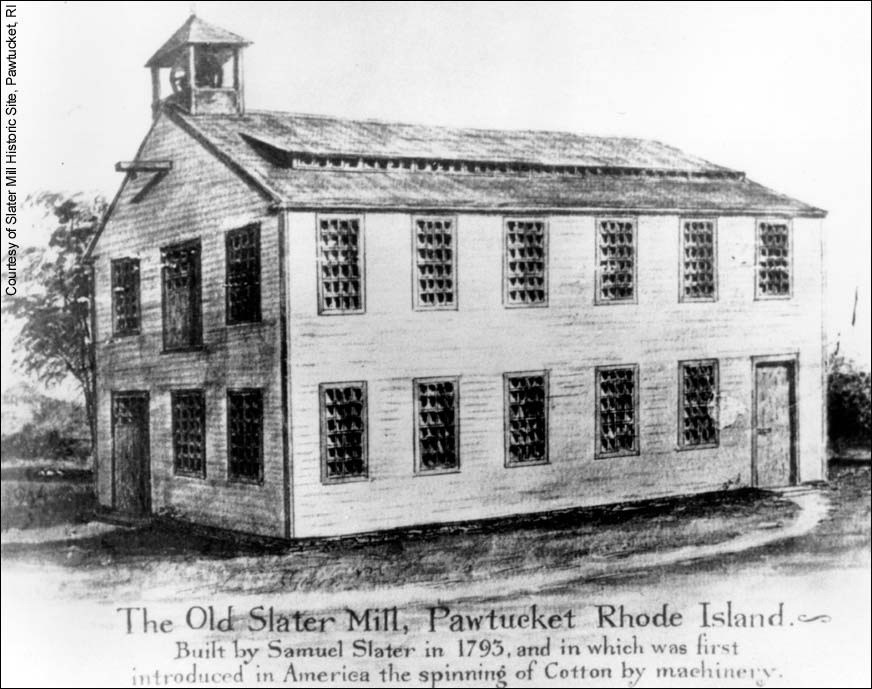

The Rhode Island System

In the United States, the first use of waterpowered spinning frames was at Slater Mill in Pawtucket, Rhode Island. Additional mills based on the pattern of Slater Mill were quickly built. Usually referred to as the "Rhode Island System," these mills borrowed heavily from standard English patterns, especially that of spinning in a factory and "putting out" the spun yarn to be woven into cloth at workers' homes. The spinning mills were housed in a variety of building types that were usually based on contemporary house types and buildings used for light industry in the region. Their appearance did not directly relate to the manufacturing activity they contained. Slater Mill was typical of early Rhode Island mills. It used traditional building construction forms and techniques to meet the requirements of the evolving industry. Early wooden mills like Slater were replaced in the early 1800s by somewhat larger structures of either rubble stone or granite block with interior wood framing. They still looked like large houses, but they were more solid and provided better protection against the danger of fire.

The Mills at Waltham

Francis Cabot Lowell and his circle of Boston friends were the first to improve upon the design and organization of the early New England textile mills. Lowell's Boston Manufacturing Company was producing cloth by 1815, utilizing power looms he had developed after observing similar machines in British factories. That mill at Waltham, Massachusetts, was the first vertically integrated factory in the United States, which means that all operations for cloth production were accomplished under one roof. Construction of the second mill at Waltham in 1816-1818 completed the evolution of the physical form, structural system, and construction technique that later would be used in Lowell.

The standard Waltham plan was rectangular, 150'-160' long (reflecting the dependability of interior overhead line shafting) by 40'-50' wide (the optimum for spaces relying on exterior windows for natural light). The four stories of open floor space had a dormer-lit gable roof, brick construction with stone foundations, and a full-height exterior stair tower centered in one of the long elevations. Initially, these mills were built either as a series of similar structures, or constructed so they could easily be expanded.

The Boott Cotton Mills

Built in the 1830s, the four original Boott mill buildings reflected the typical Waltham mill structure. The four rectangular brick "boxes" each had four stories and a dormer-lit attic, water wheels, and a basement. Stair towers centrally located on the exterior of each building provided access to upper floors.

As the century progressed, new technologies affected the millyard's development. Structures were added. The development of new means of fire protection such as ceiling sprinklers and better lineshafting to run machinery reduced the danger of fires spreading, allowing existing buildings to be connected. As sources of artificial lighting were introduced, the original width of buildings was increased. The introduction of steam power made it possible to construct several additional large buildings. The complex demonstrates the challenges of expanding on an increasingly restrictive site, bounded by a canal and a river. The Boott Mill complex is one of the few corporations at Lowell that managed to expand on its site while retaining and enhancing the architectural quality of the millyard.

Questions for Reading 3

1. Where had industrial development begun in the United States before Lowell was established?

2. How were the operations of Slater Mill different from those of the Boston Manufacturing Company?

3. Why was brick considered a better construction material for a mill than wood?

4. Why do you think the stair towers were placed on the exterior of the mill?

Reading 3 was compiled and adapted from Laurence F. Gross and Russell A. Wright, "Historic Structure Report-History Portion, Boott Mill Complex, Lowell National Historical Park," Lowell, MA: National Park Service, 1985; and Robert Weible, "Lowell National Historical Park" (Middlesex County, Massachusetts) National Register of Historic Places Registration Form, Washington, D.C.: U.S. Department of the Interior, National Park Service, 1985.

Visual Evidence

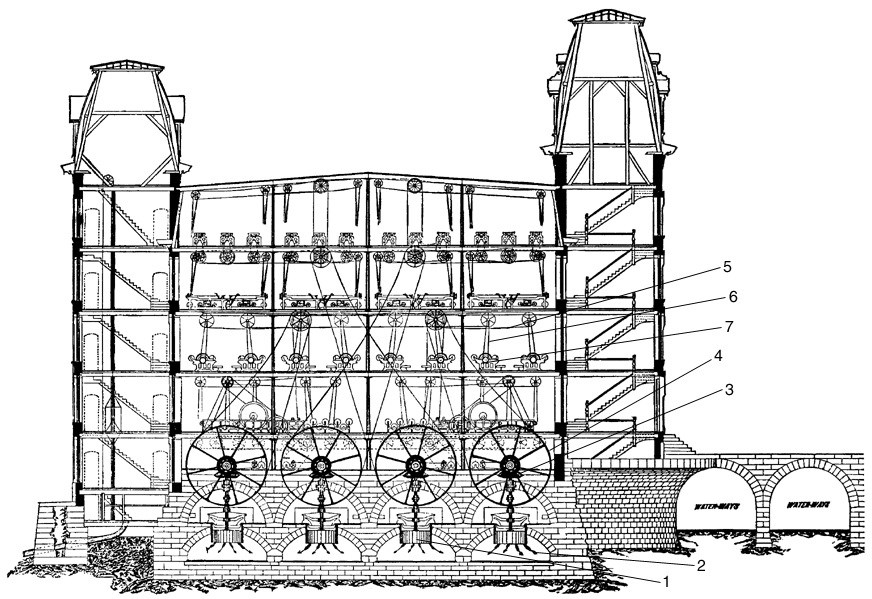

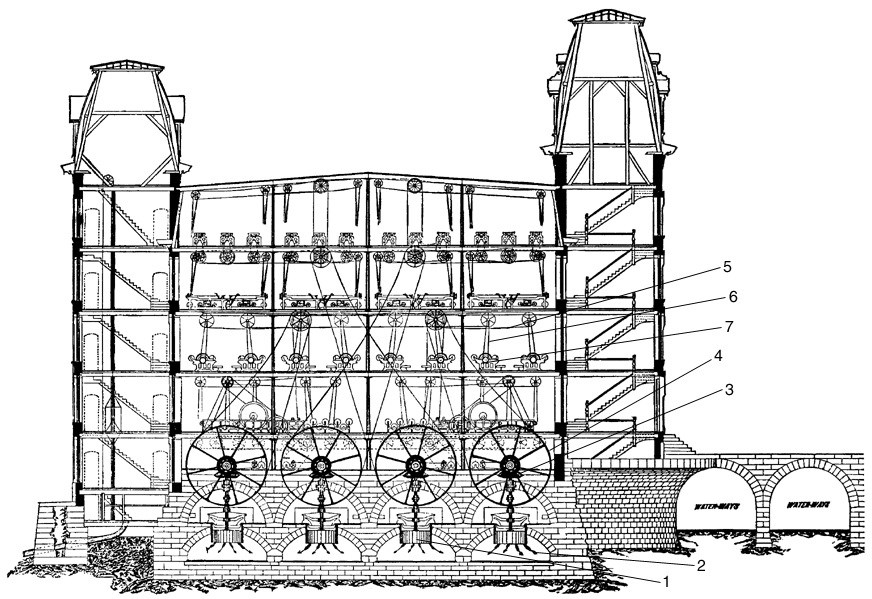

Drawing 1: Transverse view of Manville Company's No. 3 Mill, Manville, RI, 1874.

(Courtesy of American Textile History Museum, Lowell, Mass.)

Drawing 1 is a transverse view of a typical textile mill with turbines. Transmission of power from water wheels or turbines was achieved by a direct drive system. Water was funneled from the canal down into the mill through an intake known as a penstock (see upper row of arches and dashed lines on Drawing 4). The water from the higher level fell, turning the turbine (1), and then returned to the river (2) or to another canal via lower level tunnels called tailraces (see lower row of arches and dashed lines on Drawing 4). Power was then transferred upstairs through the complex series of gears (3), wheels (4), and belts shown. Eventually the power turned the overhead line shafts (5) on each floor. Individual leather belts (6) running on pulleys connected each individual textile machine (7) to the line shafts.

Questions for Drawing 1

1. Identify all of the numbered items on the drawing.

2. How was water used to create power for the mills?

3. What seasonal problems might water-powered mills like the Boott have encountered?

Visual Evidence

Drawing 2: Conjectural drawing of Almy, Brown, and Slater's Mill, 1793.

(Courtesy Old Slater Mill Association)

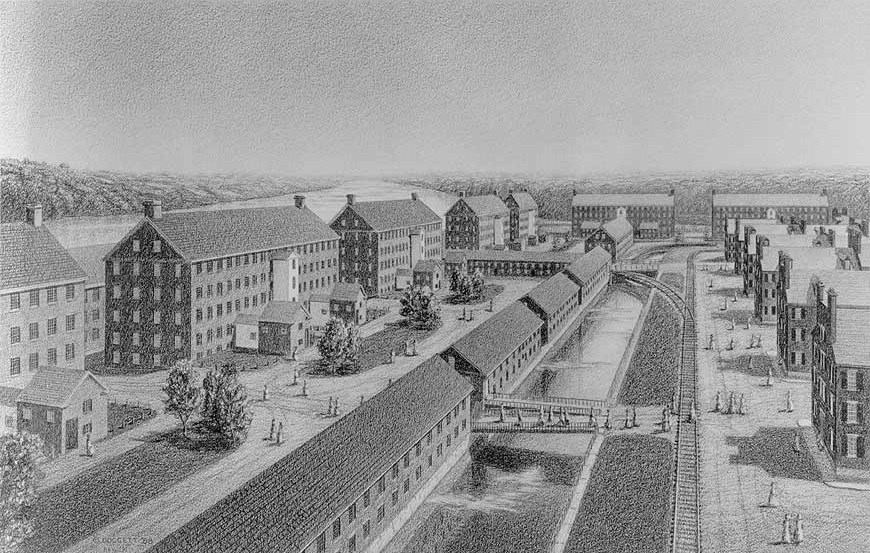

(Lowell National Historical Park; Kirk Doggett, Illustrator)

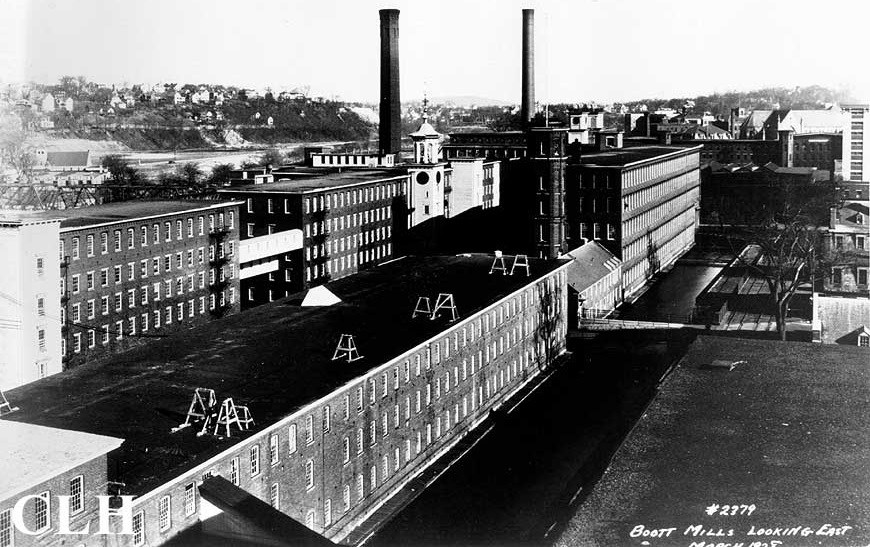

Photo 1: Boott Cotton Mills, March 1928

(University of Massachusetts Lowell, Center for Lowell History)

Many factors influenced factory design. When the first mills in the Boott millyard were constructed in the 1830s, they reflected the standard type of factory construction for the times. Drawing 3 and Photo 1 show similar views of the Boott millyard approximately 75 years apart. Several of the original freestanding Boott mills appear to the left in Drawing 3. Secondary buildings, the canal, and boardinghouses for workers appear to the right.

Questions for Drawings 2, 3, & Photo 1

1. Many Americans were influenced by negative public opinion about industry in the early years of the Industrial Revolution. Which of the two mill designs shown in Drawings 2 and 3 do you feel would blend into the existing American landscape better and be a less threatening industrial form? Explain.

2. Based on what you already know, which type of mill looks as if it would better withstand machinery vibrations and better guard against fire? Explain.

3. What reasons can you give for constructing larger mills like those shown in Drawing 3?

4. Compare and contrast Drawing 3 and Photo 1. What features shown in the drawing do you see in the photo? What are some of the changes that appear to have taken place over time?

5. What evidence of a new source of power for the Boott Mills can be detected in Photo 1?

Visual Evidence

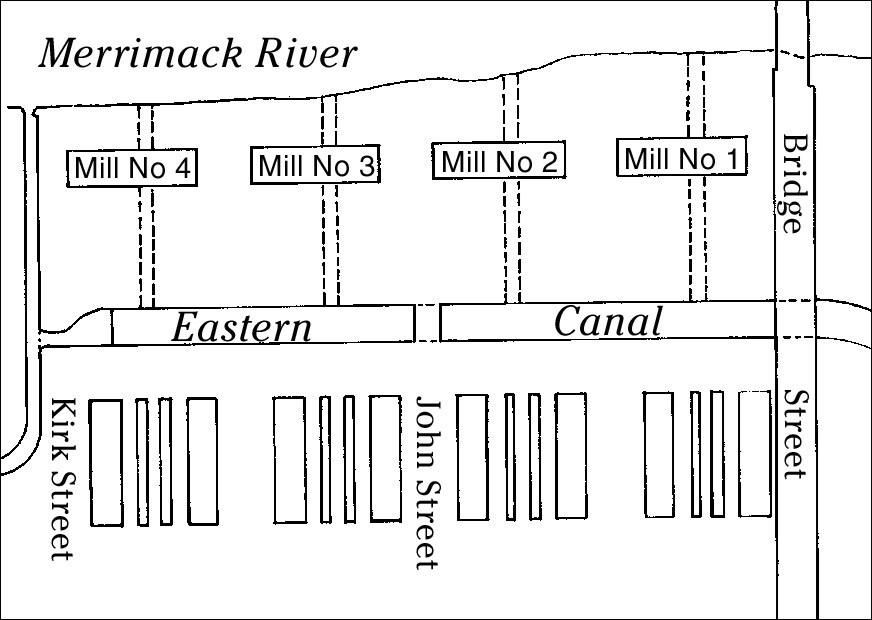

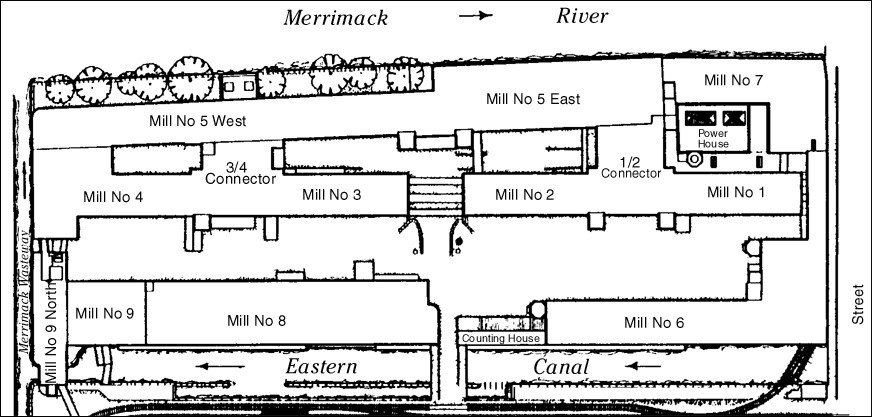

Drawing 4: Original plan of Boott millyard.

(Lowell National Historical Park; Nicholas Wyman, Illustrator)

(Timothy Short-Russell, Boott Mills Recording Project, Historic American Engineering Record, 1986)

Originally, the Boott millyard was more open. The mills were freestanding and had individual tunnels known as penstocks delivering water from the canal to the mill's water wheels. Tailraces would then return the water to the river (the penstocks and tailraces are indicated by dashed lines on Drawing 4). Eventually, newer, larger mills were built as shown in Drawing 5. New sources of power are also evident (the powerhouse in Drawing 5). Steam and electricity allowed the millyard to expand and run more efficiently.

Questions for Drawings 4 & 5

1. Compare and contrast the two drawings. Highlight the original mills still evident in Drawing 5.

2. Based on what you already know, what did these four original mills look like? Why were they separated? Why were they later able to be connected?

3. Look at all that has been built up around the original mills. What might explain this construction?

4. What two sources of power for the mills are evident in the drawings? Which one allowed the mill to run more efficiently?

Putting It All Together

The Boott Mills were part of a larger industrial complex in Lowell. Like any system that has many subsystems, the Boott was just one part of a whole. By looking at what influenced the development of the Boott millyard, students can more easily understand the workings of the industrial system at Lowell.

Activity 1: Role Play

Construction of industrial sites moved at a rapid pace in the first years of the development of Lowell. Have students assume the roles of local farmers and villagers taking part in a town meeting. Based on what they have read and the visual material they have studied, have them consider the amount of construction that took place in Lowell's early years. Have several students make short speeches describing 1) the frenzied pace of construction, 2) their reaction to the types of activities they have witnessed, and 3) the changes to the land. Now have several other students discuss what would happen to their current ways of life if their own neighborhoods suddenly underwent such rapid and dramatic changes.

Activity 2: Building a Mill

Many materials were needed for the construction of a mill such as the Boott. Have students compile a list of the basic things necessary to build a mill (construction materials, equipment, and people). Remind them that early in Lowell's history there were no cranes or steam shovels. Ask them to speculate on how a four- or five-story mill building would have been constructed--for example, how would you move heavy bricks to upper portions of a wall or how would you dig a deep canal for waterpower? Discuss the lists to elicit understanding of the complexity of industrial start-up. (You may wish to have an architectural historian or someone in the building trades discuss the lists with the students.) Students who are particularly interested in how textile mills were constructed and operated might elect to build a three-dimensional model of a mill and explain what would be a proper location for it. David McCauley's Mill (Boston: Houghton Mifflin Co., 1983) is a particularly useful source for this activity.

Activity 3: The Mill as a System

A system is defined as a group of interacting elements forming a collective entity. The Boott Mills complex is an example of the mill as a system. Power, people, machinery, capital, and many distinct subsystems came together to produce textiles. A school is also a system with many subsystems coming together to create the eventual product: educated persons. Have students identify the elements (people, places, objects, outside elements, etc.) that come together to produce a school system. Have students think again of what they learned from Reading 2, "The Mill as a System," and have them list internal and external forces that affected the smooth running of the operation. Then have students make a list of positive and negative forces that act on a school system. Have them develop a plan for action that might moderate negative forces.

Activity 4: Local Industrial Development

Each community has its own history. Much of the information in this lesson has come from local documents, historic photographs and sketches, and local histories. Although your community may not have had a textile mill like the Boott Cotton Mills, other historic industries may have helped your community prosper. Have the students research their own community to discover what industries were important to the growth of the area. Ask your students to choose a local industry or business historically important to their community and, in essays or oral presentations, report on when it started, how long it existed, and its contribution to the local economy. Also have students compare the local industry to a textile mill such as Boott. Have them determine if the local industry is similar to or different from the industries in Lowell. Ask them to include information about what conditions supported the development of their local industry and explore why that particular industry has or has not remained in the region.

Building America's Industrial Revolution: The Boott Cotton Mills of Lowell, Massachusetts--

Supplementary Resources

By looking at Building America's Industrial Revolution: The Boott Cotton Mills of Lowell, Massachusetts, including what influenced the development of the Boott millyard, students can more easily understand the workings of the industrial system at Lowell. Those interested in learning more will find that the Internet offers a variety of materials.

Lowell National Historical Park

Lowell National Historical Park is a unit of the National Park System. The park's web page details the history of the park and visitation information. The site also offers a photographic tour of Lowell in the page titled "Images of Lowell."

Places Where Women Made History

The National Register of Historic Places, a division of the National Park Service, offers a travel itinerary on Places Where Women Made History. The site features Lowell National Historical Park as an example of how the Industrial Revolution produced a new way of life for American women.

Center for Lowell History

The University of Massachusetts Lowell, Center for Lowell History offers a wealth of information about Lowell, Massachusetts. Included on the site is special collection called "The Blue Plate Special: An eclectic View of the Lowell Historical Society's Collection" and a comprehensive "links" page that directs you to archives, timelines, research topics, and much more.

Slater Mill

Slater Mill Historic Site provides an overview of the site as well as the story of Samuel Slater.

Modern History Sourcebook

The Modern History Sourcebook is one of a series of internet history primary sourcebooks created by the History Department of Fordham University in New York. Included on their web page is account of Harriet Robinson as a "Lowell mill girl."

Lowell Mill Girls and the Rhetoric of Women's Labor Unrest

Lowell Mill Girls and the Rhetoric of Women's Labor Unrest is an essay examining impact of the Industrial Revolution on working women. The essay was written by Catherine Lavender at the Department of History, The College of Staten Island of The City University of New York.

For Further Reading

For further reading about the development of the textile mills in Lowell and America's Industrial Revolution consider the following useful works: David Macauley, Mill (Boston, Houghton Mifflin Co., 1983) and William H. Pierson, American Buildings and Their Architects: Technology and the Picturesque, the Corporate and the Early gothic Styles (New York: Doubleday and Company, 1978). Sources for related topics include Thomas Dublin, Farm to Factory: Women's Letters 1830-1860 (New York: Columbia University Press, 1981; revised edition, 1993) which includes primary sources related to Lowell's early women mill workers and Katherine Patterson, Lyddie (New York: Lodestar Books, 1991) which is a historic novel based on factual accounts of Lowell's "mill girls."

Tags

- urban living

- industrialization

- industrial history

- labor history

- workers

- women and the economy

- women's history

- textile industry

- textile mills

- massachusetts

- massachusetts history

- national register of historic places

- nrhp listing

- teaching with historic places

- twhp

- industrial revolution

- science

- womens history

- women in the workplace

- womens work

- mid 19th century

- women in science and technology

- migration and immigration

- immigration and migration

- late 19th century

- gilded age

- twhplp